Mordenite/beta zeolite/analcime porous coexisting material and method for synthesizing same

A technology of mordenite and beta zeolite, which is applied in the field of mordenite/beta zeolite/analcite porous symbiotic materials and their preparation, can solve the problems of low activity, single pore size of porous materials, weak acidity, etc., and achieve good catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

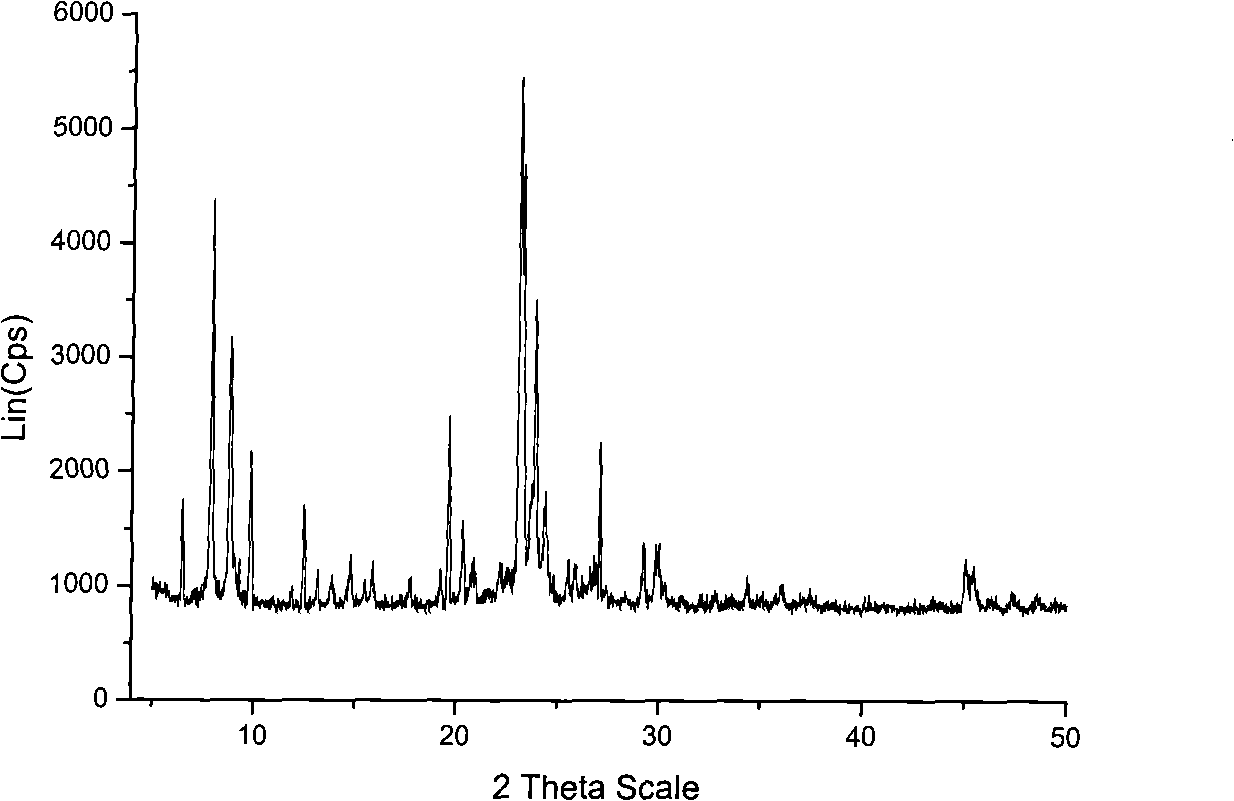

[0021] Take 284 grams of sodium metasilicate, dissolve it into solution A with 300 grams of distilled water, take 16.7 grams of aluminum sulfate, and make solution B with 100 grams of distilled water, slowly pour B solution into A solution, stir vigorously, and then add 24.4 grams of B Diamine and 29.4 grams of tetraethylammonium hydroxide are used as the template agent M. After stirring for a period of time, the pH value is adjusted at 12 with sodium hydroxide and dilute sulfuric acid, and the molar ratio of the control sol is: Si: Al: M: H 2 O:OH - =1:0.05:0.4:40, put the mixed solution in an autoclave, keep it warm at 160°C for 40 hours, then take it out and wash it twice, dry at 120°C for 4 hours, and roast at 550°C for 3 hours to obtain Mordenite / β Zeolite / alalcite porous intergrowth material, XRD diffraction pattern as figure 1 As shown, there are d-spacing maxima at 13.52, 11.32, 9.47, 8.96, 7.07, 6.71, 4.51, 4.15, 3.98, 3.76, 3.65, 3.53, 3.47, 3.31, 3.02 Angstroms. Q...

Embodiment 2~6

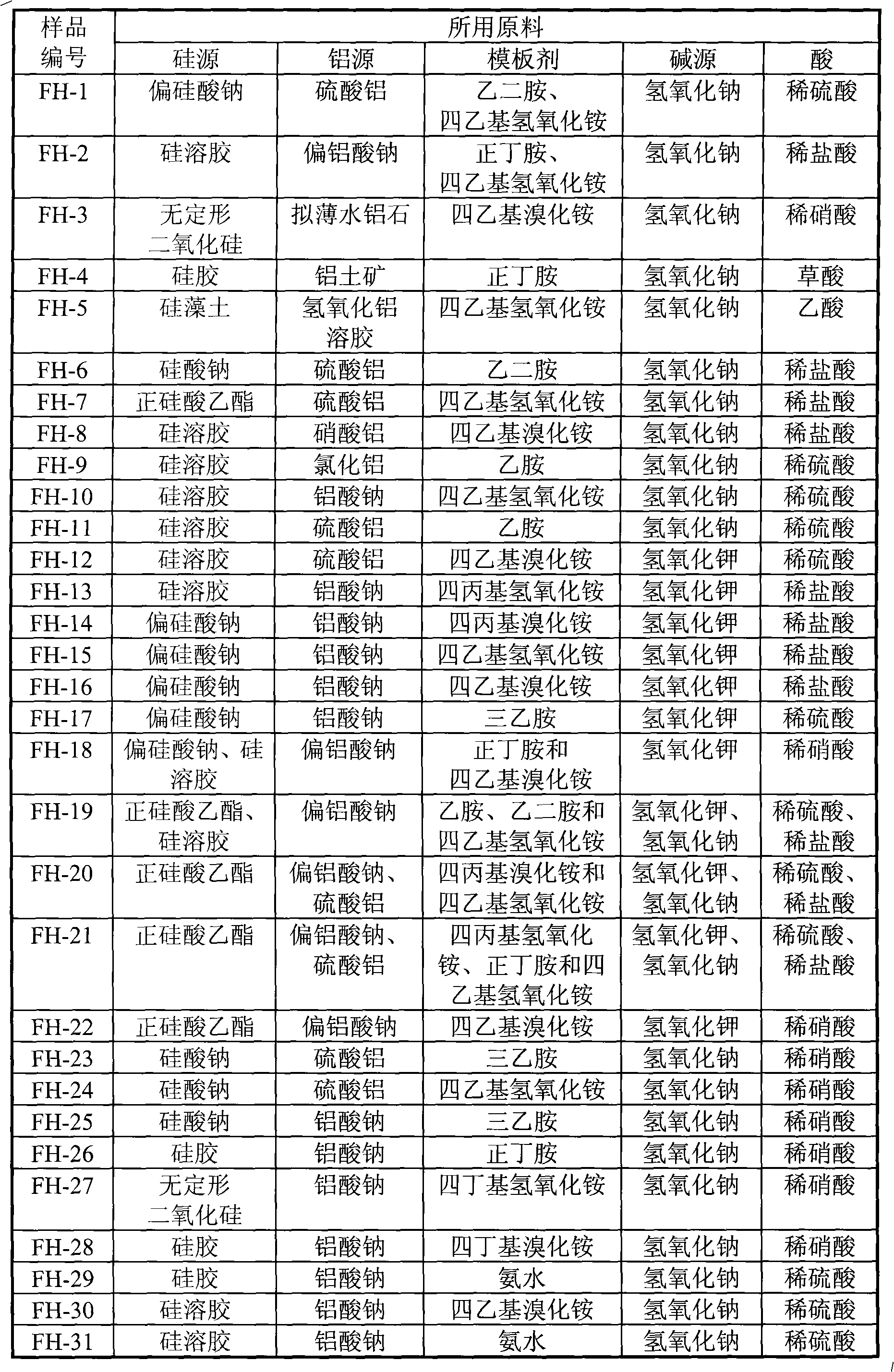

[0023] According to the method of Example 1, the raw materials used are as shown in Table 4, and the pH of the solution is controlled to be different, and mordenite / beta zeolite / analcite symbiotic materials were synthesized respectively, as shown in Table 1. The XRD diffraction pattern is the same as that of Example 1, and the proportions of zeolite beta, mordenite and analcime in the intergrowth material are shown in Table 3.

[0024] Table 1

[0025] Example

Embodiment 7~17

[0027] According to the method of Example 1, the raw materials used are shown in Table 4, and the different molar ratios of the solutions are controlled, and the mordenite / beta zeolite / analcite symbiotic materials synthesized respectively are shown in Table 2. The XRD diffraction pattern is the same as that of Example 1, and the proportions of zeolite beta, mordenite and analcime in the intergrowth material are shown in Table 3.

[0028] Table 2

[0029] Example

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com