Preparation process of one-dimensional pyromelane nanometer titanium dioxide

A technology of titanium dioxide and brookite, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., to achieve the effect of simple preparation process, wide parameter adjustable range and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

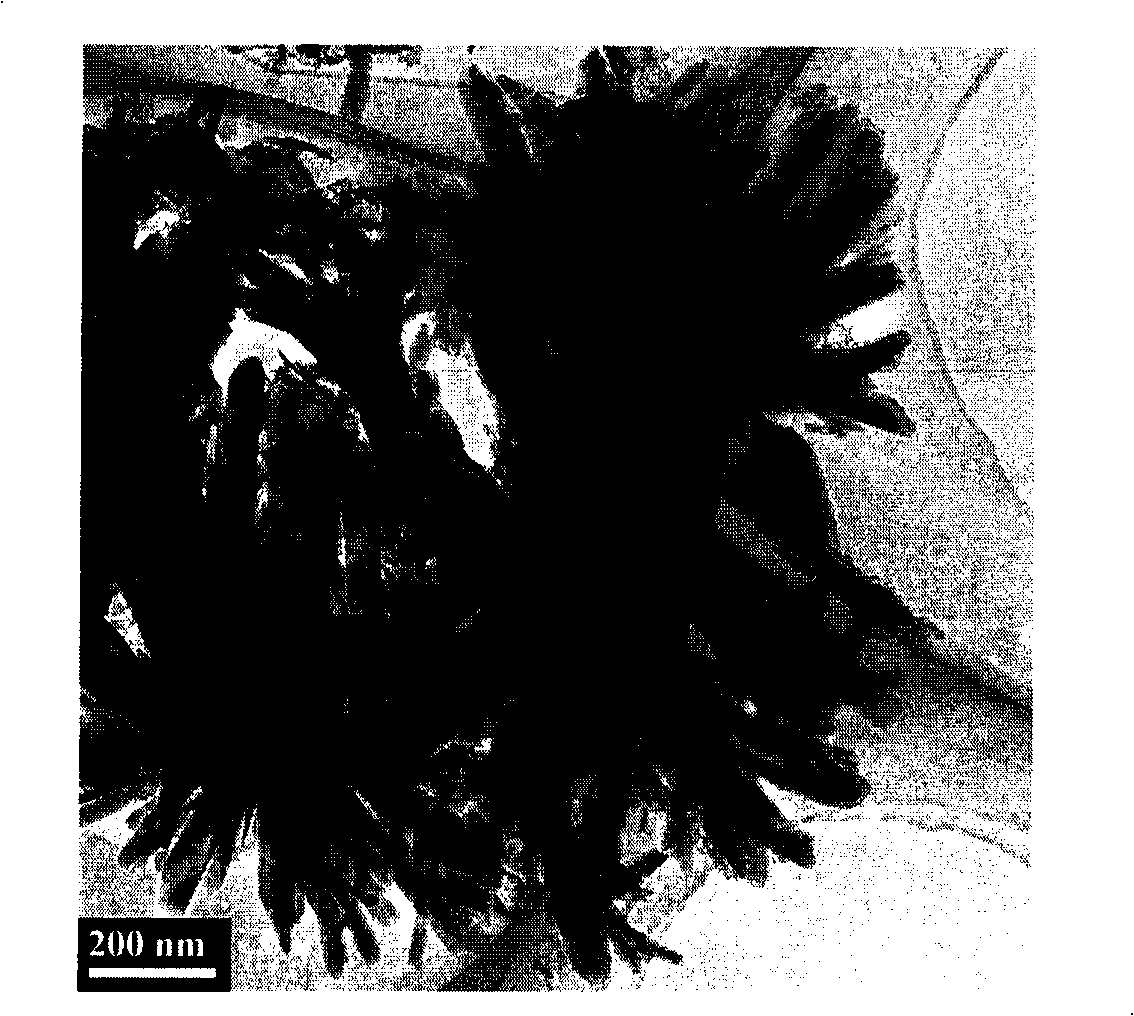

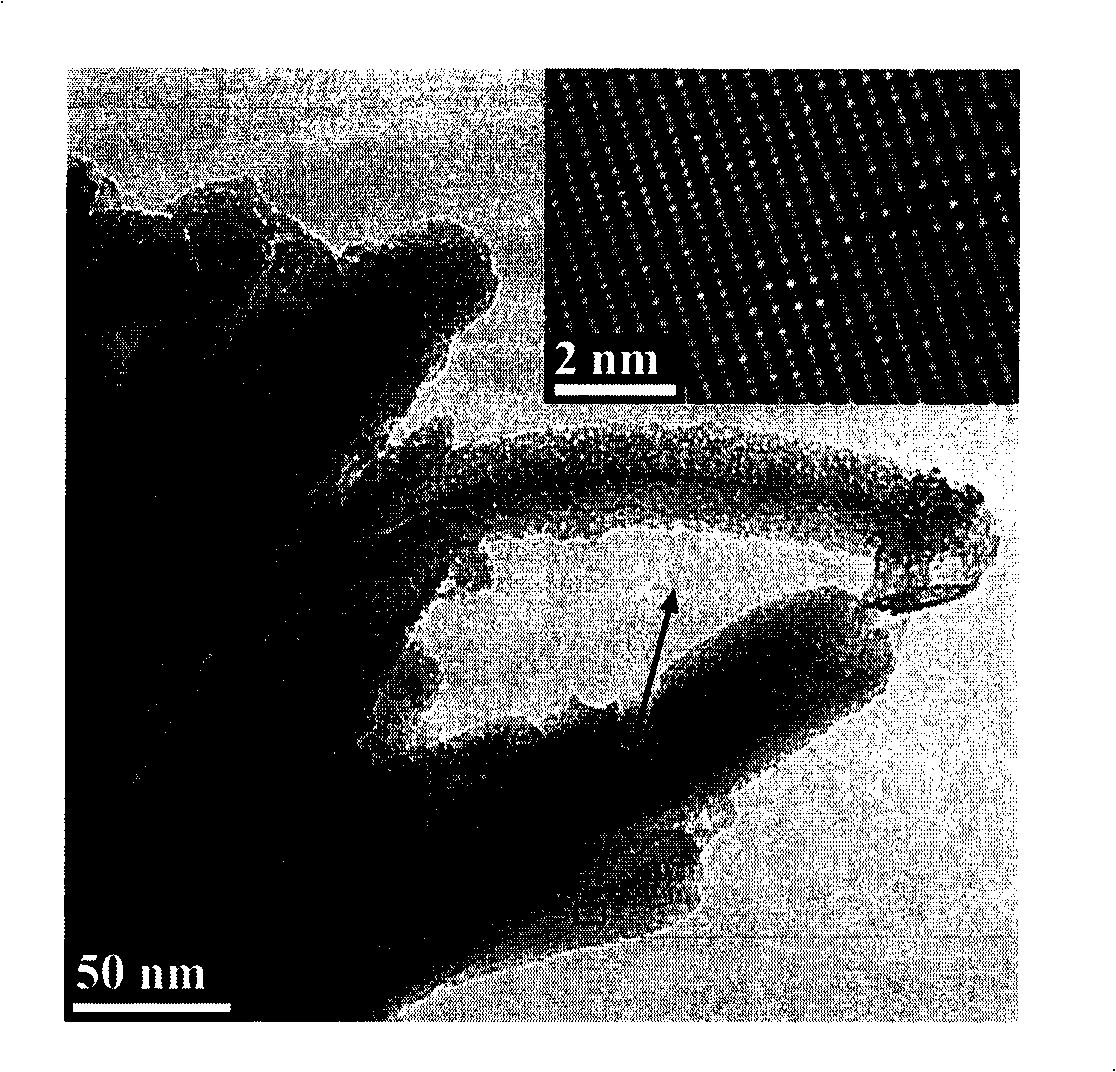

[0021] 8 ml of isopropyl titanate and 1.50 g of sodium chloride were added to 65 ml of ammonia water with a mass fraction of 20%, and the isopropyl titanate was rapidly hydrolyzed while stirring vigorously to mix them uniformly. Then the suspension was put into a Teflon-lined stainless steel autoclave and reacted at 433K for 48 hours. After the reaction, the precipitated product was washed with a large amount of deionized water and dilute hydrochloric acid, and then dried under normal pressure at 363K for 12 hours to obtain brookite-type titanium dioxide nanorods.

[0022] The prepared nano-rods are in the shape of multiple aggregated flowers, the diameter of a single nano-rod is 20-50 nanometers, the length is 500-2500 nanometers, and the purity is over 99%.

Embodiment 2

[0024] 5 ml of isopropyl titanate and 0.55 g of potassium chloride were directly added to 50 ml of ammonia water with a mass fraction of 10%, and the isopropyl titanate was rapidly hydrolyzed while stirring vigorously to mix them uniformly. Then the suspension was put into a Teflon-lined stainless steel autoclave and reacted at 393K for 72 hours. After the reaction, the precipitated product was washed with a large amount of deionized water and dilute hydrochloric acid, and then dried under normal pressure at 353K for 18 hours to obtain brookite-type titanium dioxide nanorods.

[0025] The prepared nano-rods are in the shape of multiple aggregated flower bouquets, the diameter of a single nano-rod is 20-50 nanometers, the length is 500-1500 nanometers, and the purity is over 99%.

Embodiment 3

[0027] 7 ml of isopropyl titanate and 4.60 g of barium chloride were directly added to 55 ml of ammonia water with a mass fraction of 25%, and the isopropyl titanate was rapidly hydrolyzed while stirring vigorously to mix them uniformly. Then the suspension was put into a Teflon-lined stainless steel autoclave and reacted at 423 K for 48 h. After the reaction, the precipitated product was washed with a large amount of deionized water and dilute hydrochloric acid, and then dried under normal pressure at 333K for 24 hours to obtain brookite-type titanium dioxide nanorods.

[0028] The prepared nano-rods are in the shape of a bouquet of multiple aggregates, the diameter of a single nano-rod is 20-50 nanometers, the length is 500-2000 nanometers, and the purity is over 99%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com