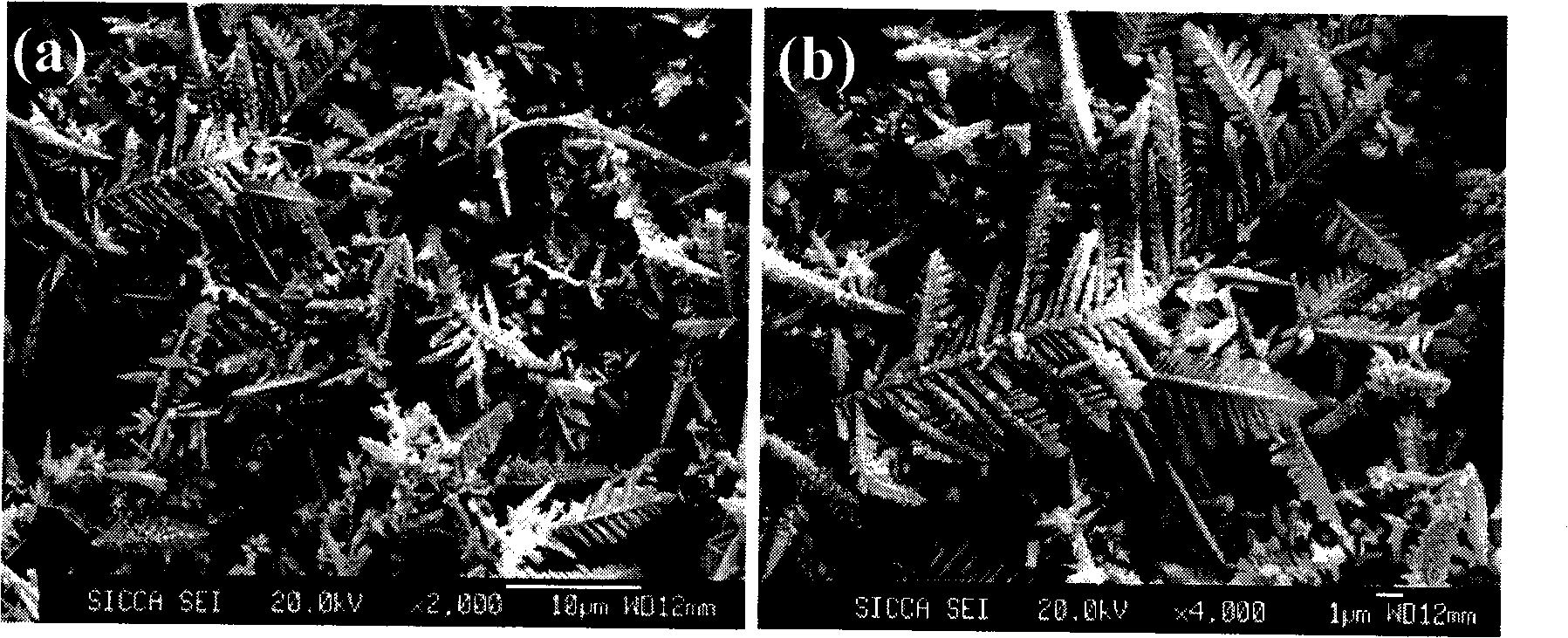

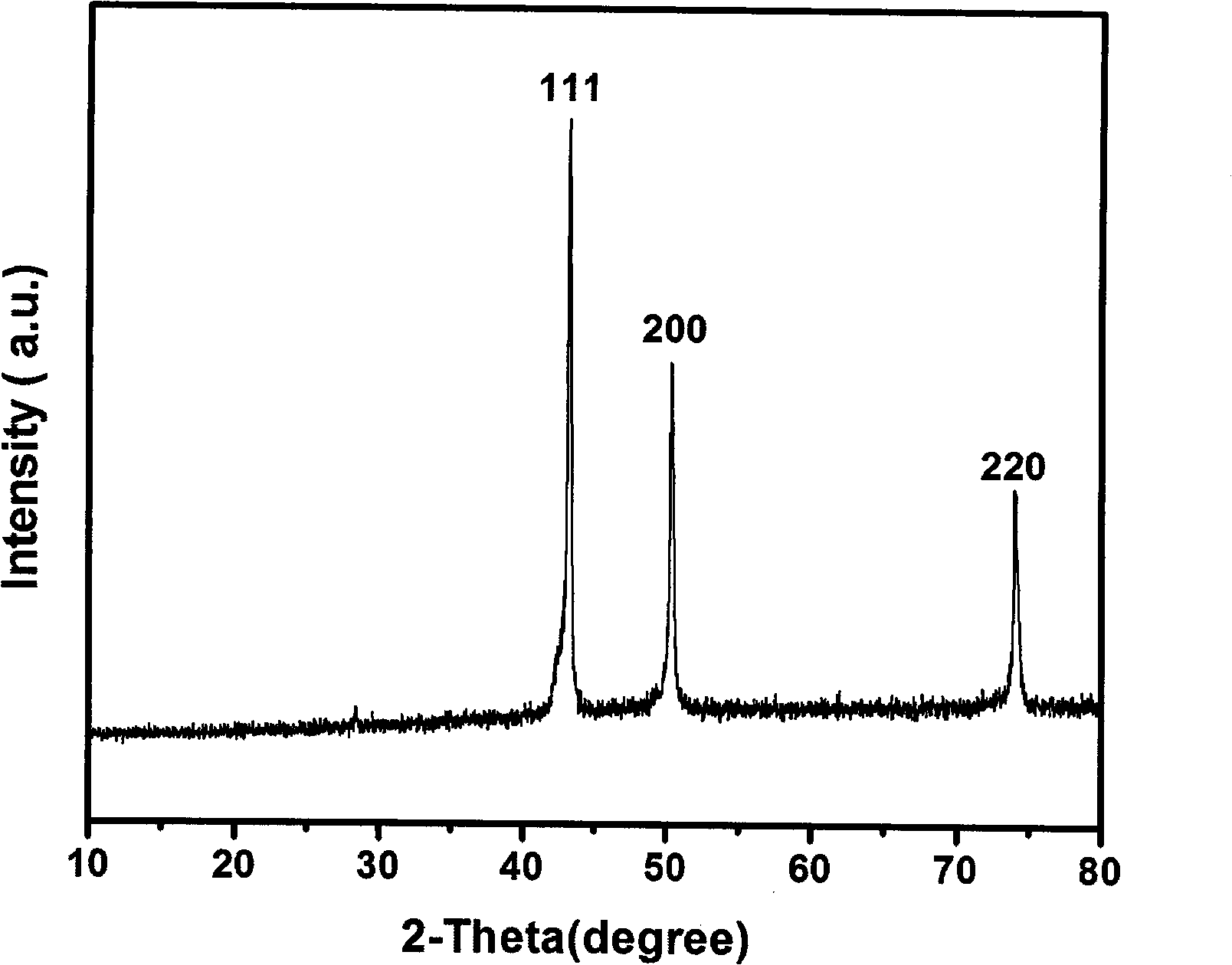

Cu dendritic single crystalline nano material and preparation method thereof

A single crystal nano, dendritic technology, applied in the direction of polycrystalline material growth, single crystal growth, single crystal growth, etc., can solve few problems, and achieve the effect of novel method, resource saving, and novel appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] This Cu dendritic single crystal nanomaterial and preparation method thereof, its specific process is as follows:

[0020] 1) Place a copper sheet (surface area about 1.5cm 2 ) polished, soaked in 30% hydrochloric acid for 8 minutes, and then placed in acetone for ultrasonication, and the obtained pure copper sheet was used as an anode;

[0021] 2) ITO conductive glass (surface area about 1.6cm 2 ) was washed with 0.1mol / L NaOH for 8 minutes, then placed in acetone for ultrasonication, and finally rinsed with deionized water as the cathode;

[0022] 3) The electrolyte is 0.5mol / L Cu(NO 3 ) 2 And 1.0mol / L citric acid, citric acid is used to adjust the pH to 1.5; electroplating is performed at a voltage of 0.8V;

[0023] 4) After 1.5 hours, take out the ITO conductive glass, and you can see a layer of light red attachment on it, which is Cu dendritic single crystal nanomaterial.

Embodiment 2

[0025] This Cu dendritic single crystal nanomaterial and preparation method thereof, its specific process is as follows:

[0026] 1) Place a copper sheet (surface area about 1.5cm 2 ) polished, soaked in 30% hydrochloric acid for 10 minutes, and then placed in acetone for ultrasonication, and the obtained pure copper sheet was used as an anode;

[0027] 2) ITO conductive glass (surface area about 1.6cm 2 ) was cleaned with 0.1mol / L NaOH for 10 minutes, then placed in acetone for ultrasonication, and finally rinsed with deionized water as the cathode;

[0028] 3) The electrolyte is 0.5mol / L Cu(NO 3 ) 2 And 1.0mol / L citric acid, citric acid is used to adjust the pH to 2; electroplating is performed at a voltage of 1V;

[0029] 4) After 2.5 hours, take out the ITO conductive glass, and you can see a layer of light red attachment on it, which is Cu dendritic single crystal nanomaterial.

Embodiment 3

[0031] This Cu dendritic single crystal nanomaterial and preparation method thereof, its specific process is as follows:

[0032] 1) Place a copper sheet (surface area about 1.5cm 2 ) polished, soaked in 30% hydrochloric acid for 9 minutes, then placed in acetone for ultrasonication, and the obtained pure copper sheet was used as an anode;

[0033] 2) ITO conductive glass (surface area about 1.6cm 2 ) was washed with 0.1mol / L NaOH for 9 minutes, then placed in acetone for ultrasonication, and finally rinsed with deionized water as the cathode;

[0034] 3) The electrolyte is 0.5mol / L Cu(NO 3 ) 2 And 1.0mol / L citric acid, citric acid is used to adjust the pH to 1.5; electroplating is performed at a voltage of 1V;

[0035] 4) After 2 hours, take out the ITO conductive glass, and you can see a layer of light red attachment on it, which is Cu dendritic single crystal nanomaterial.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com