Method for preparing polymer solar cell

A solar cell and polymer technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as large fluctuations in the efficiency of polymer cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

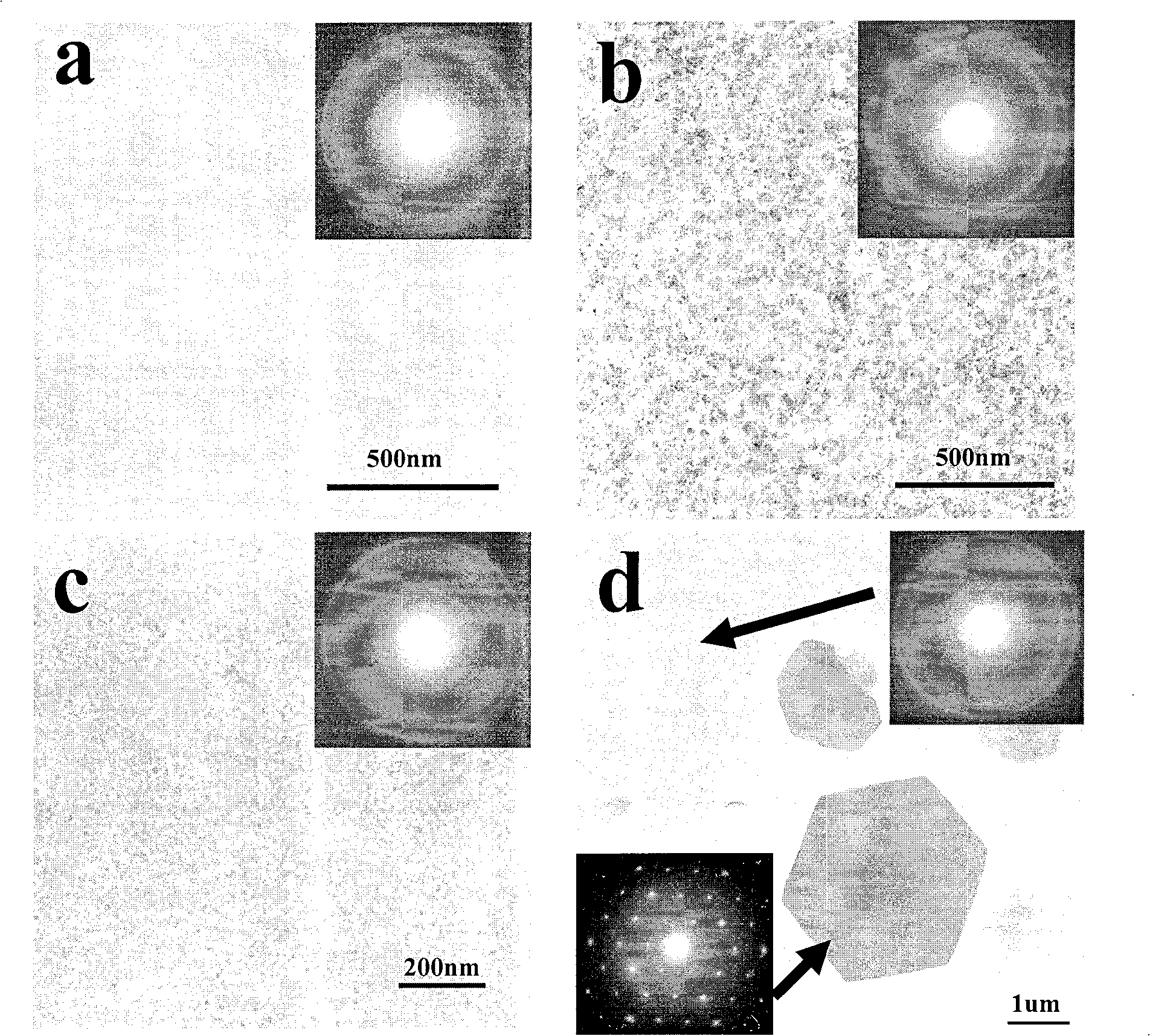

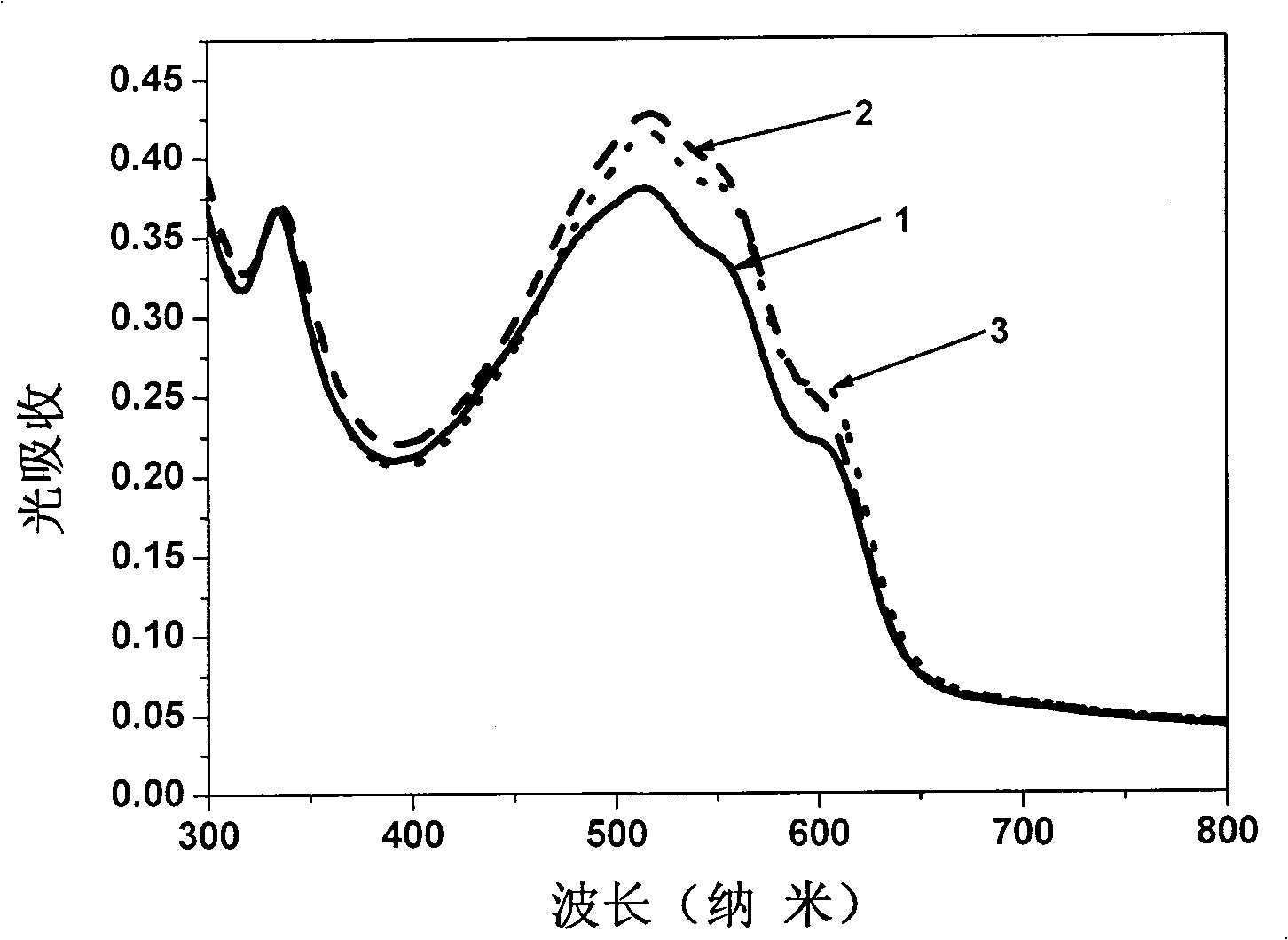

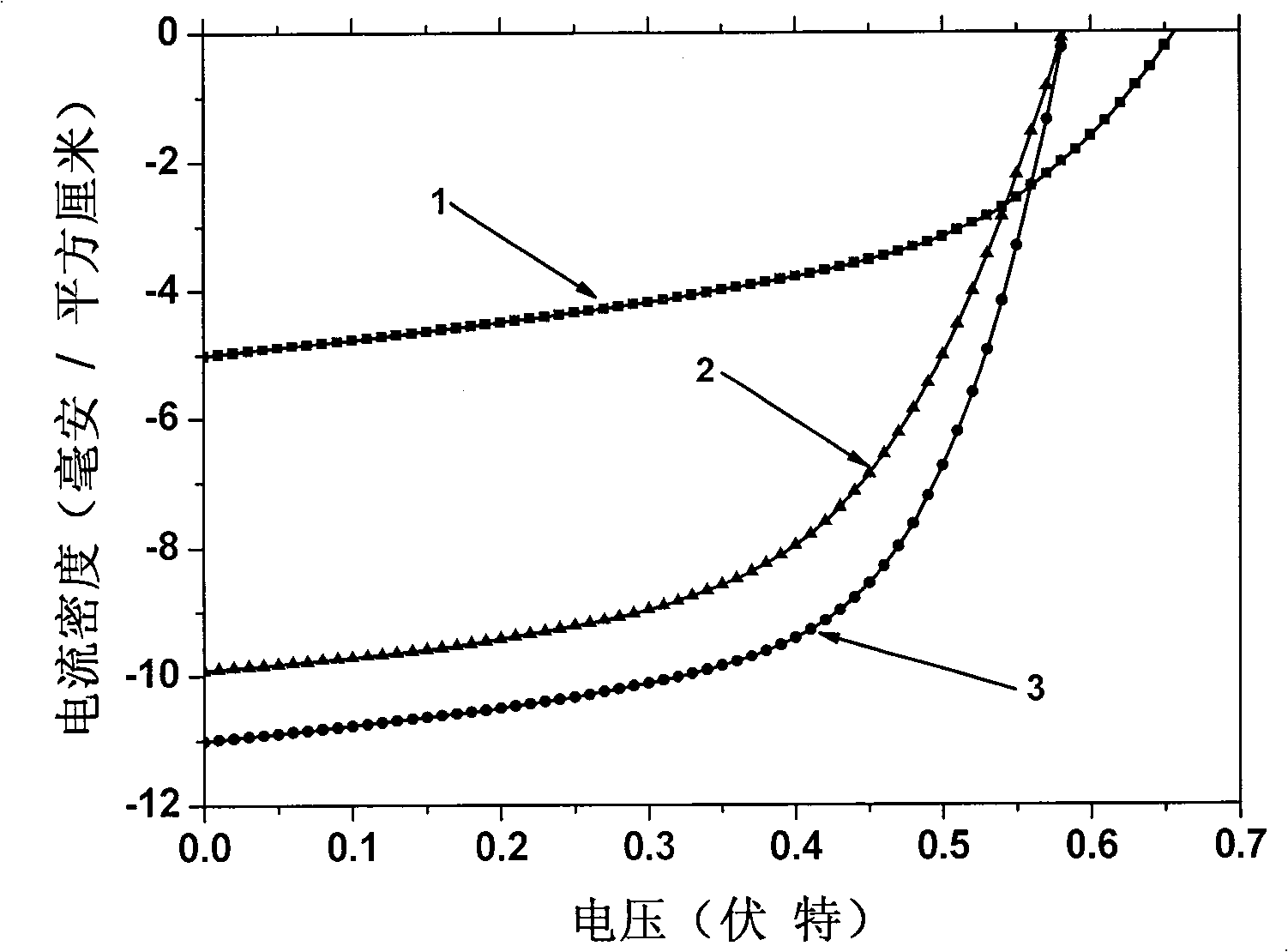

[0018] Experimental example 1: At room temperature, dissolve P3HT and PCBM with a mass ratio of 1:1 in o-dichlorobenzene (ODCB) solvent to prepare a mixed solution with a total concentration of 20 mg / ml, and then spin-coated with a spin coater A 100-nanometer film is obtained; the film is first placed in 1 times the saturated vapor pressure of tetrahydrofuran for 5 seconds at room temperature, and then the treated film is placed in 0.8 times the saturated vapor pressure of carbon disulfide for 15 seconds. Finally, an electrode with a thickness of 100 nanometers is evaporated to obtain a polymer solar cell. The average efficiency of the obtained original device is 3.87%.

experiment example 2

[0019] Experimental example 2: At room temperature, dissolve P3HT and PCBM with a mass ratio of 1:2 in o-dichlorobenzene (ODCB) solvent to form a mixed solution with a total concentration of 18 mg / ml, and then spin-coated with a spin coater A 60-nanometer film is obtained; the film is first placed in 1 times the saturated vapor pressure of tetrahydrofuran for 5 seconds at room temperature, and then the treated film is placed in 0.8 times the saturated vapor pressure of carbon disulfide for 15 seconds. Finally, a polymer solar cell is obtained after the electrode is evaporated with a thickness of 80 nanometers. The average efficiency of the obtained original device was 2.91%.

experiment example 3

[0020] Experimental example 3: At room temperature, dissolve P3HT and PCBM with a mass ratio of 2:1 in o-dichlorobenzene (ODCB) solvent to form a mixed solution with a total concentration of 18 mg / ml, and then spin-coated with a spin coater Obtain an 80-nanometer film; first place the film at room temperature at 1 times the saturated vapor pressure of tetrahydrofuran for 5 seconds, and then place the treated film at 0.8 times the saturated vapor pressure of carbon disulfide for 15 seconds. Finally, an electrode with a thickness of 120 nanometers is evaporated to obtain a polymer solar cell. The average efficiency of the obtained original device was 3.11%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com