Quality improving agent for foods and foods

A quality improver, food technology, applied in the field of food quality improver and food, to achieve the effects of excellent storage stability, prevention of starch aging, and simple manufacturing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

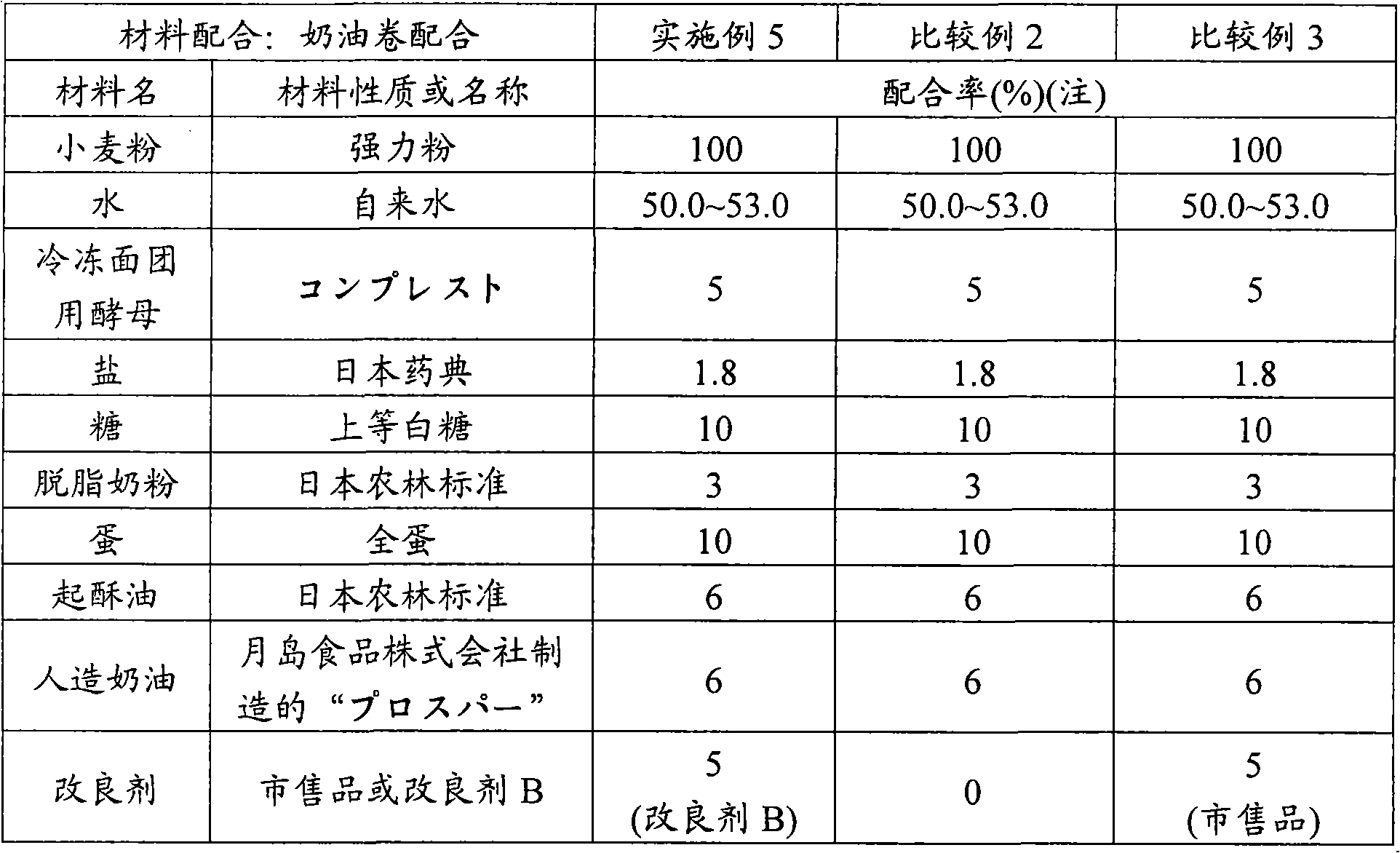

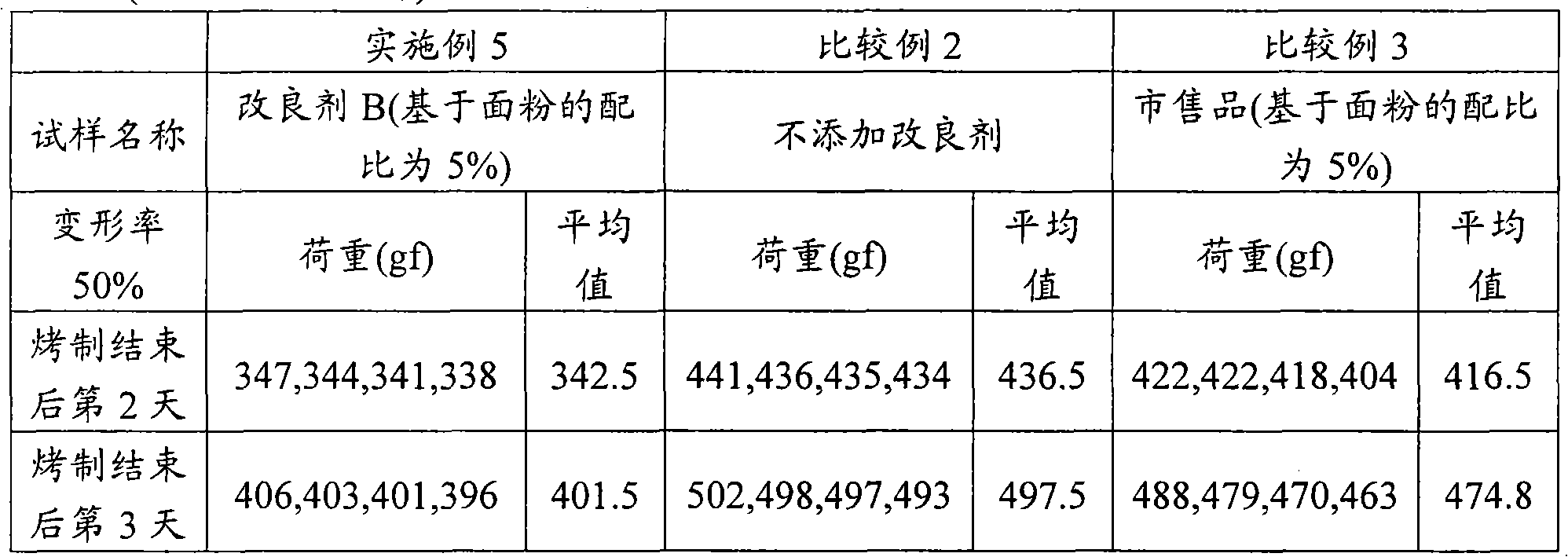

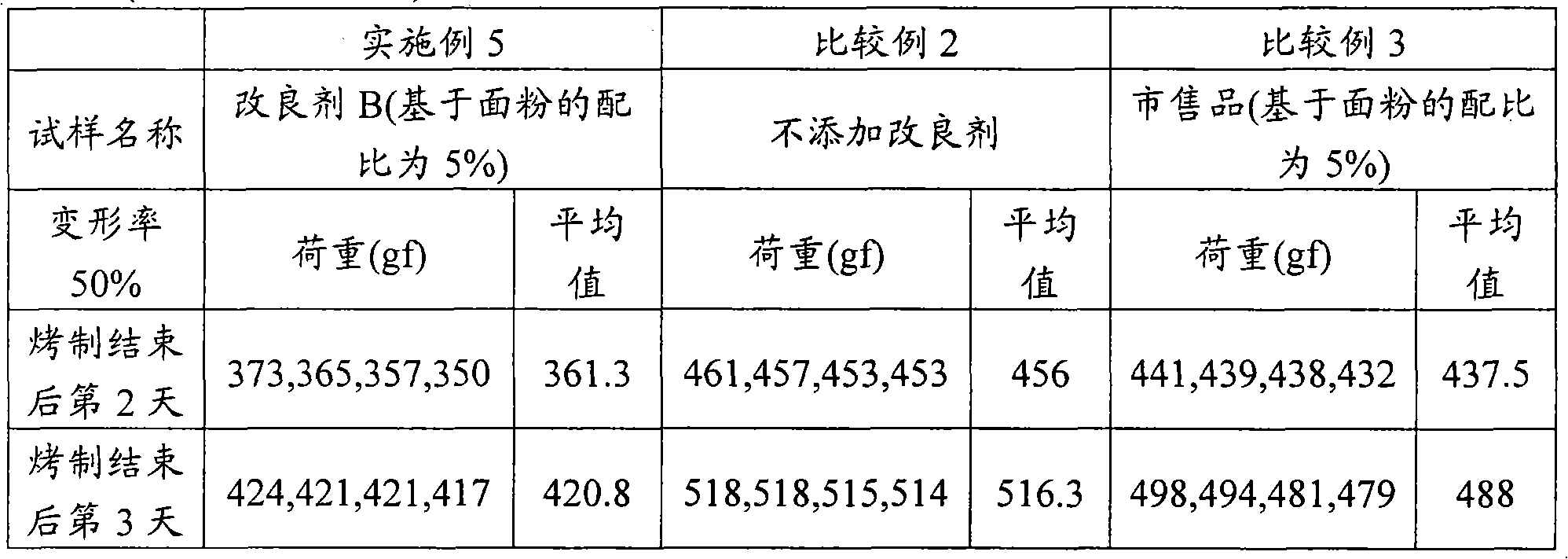

Examples

Embodiment 1

[0055] 50 g of HLB11 sucrose stearate ("RYOTO Sugar Ester S-1170" manufactured by Mitsubishi Chemical Foods Co., Ltd.) was dispersed in 50 g of ethanol at room temperature, and 700 g of oligosaccharide aqueous solution (Japanese food "High maltose (high maltose) MC-45" manufactured by Kagaku Co., Ltd.) (aqueous solution of 610 g of oligosaccharide solution and 90 g of desalted water) were mixed and stirred for 30 minutes (hereinafter referred to as "oligosaccharide solution"). On the other hand, 20 g of monoglyceride succinate ("Step SS" manufactured by Kao Corporation) was dispersed in 180 g of desalted water and stirred while raising the temperature to 60°C to obtain an aqueous dispersion of a layered structure. The above-mentioned oligosaccharide solution was cooled to 55° C., and the above-mentioned aqueous dispersion of the layered structure of monoglyceride succinate was added, followed by stirring for 20 minutes. Then, it cooled to 45 degreeC, and prepared 1000g of food...

Embodiment 2

[0058] 35 g of HLB11 sucrose stearate ("RYOTO Sugar Ester S-1170" manufactured by Mitsubishi Chemical Foods Co., Ltd.) was dispersed in 50 g of ethanol at room temperature, and 680 g of oligosaccharide aqueous solution (Mitsuwa Starch Industry Co., Ltd. "Oligotose") was mixed and stirred for 30 minutes (hereinafter referred to as "oligosaccharide liquid"). On the other hand, 35 g of monoglyceride succinate ("Step SS" manufactured by Kao Corporation) was dispersed in 200 g of desalted water and stirred while raising the temperature to 60° C. to obtain an aqueous dispersion of a layered structure. The above-mentioned oligosaccharide solution was cooled to 55° C., and the above-mentioned aqueous dispersion of the layered structure of monoglyceride succinate was added, followed by stirring for 20 minutes. Then, it cooled to 45 degreeC, and prepared 1000g of food quality improvement agents (henceforth "improvement agent B"). In addition, the confirmation of the lamellar structure ...

Embodiment 3

[0061] The sucrose stearate of HLB5 ("RYOTOSugar Ester S-570" manufactured by Mitsubishi Chemical Foods Co., Ltd.) was used instead of the sucrose stearate of HLB11 in Example 2. Method, prepare 1000 g of food quality improver (hereinafter referred to as "improver C"). Using this improver C, a sponge cake (cake C) was baked in the same manner as in Example 1. This sponge cake was stored at 4° C. for one week, and the change in the water content of the inner phase portion and the change in hardness measured by a rheometer were evaluated. The evaluation results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com