Inverted-type roofing heat-insulation light plate and preparation method thereof

An inverted roof, thermal insulation technology, applied to roofs, roof coverings, roofs using flat/curved panels, etc., can solve problems such as complex construction techniques, increased construction costs, and easy damage to insulation boards, and achieve simplified construction Craftsmanship, extended service life, long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

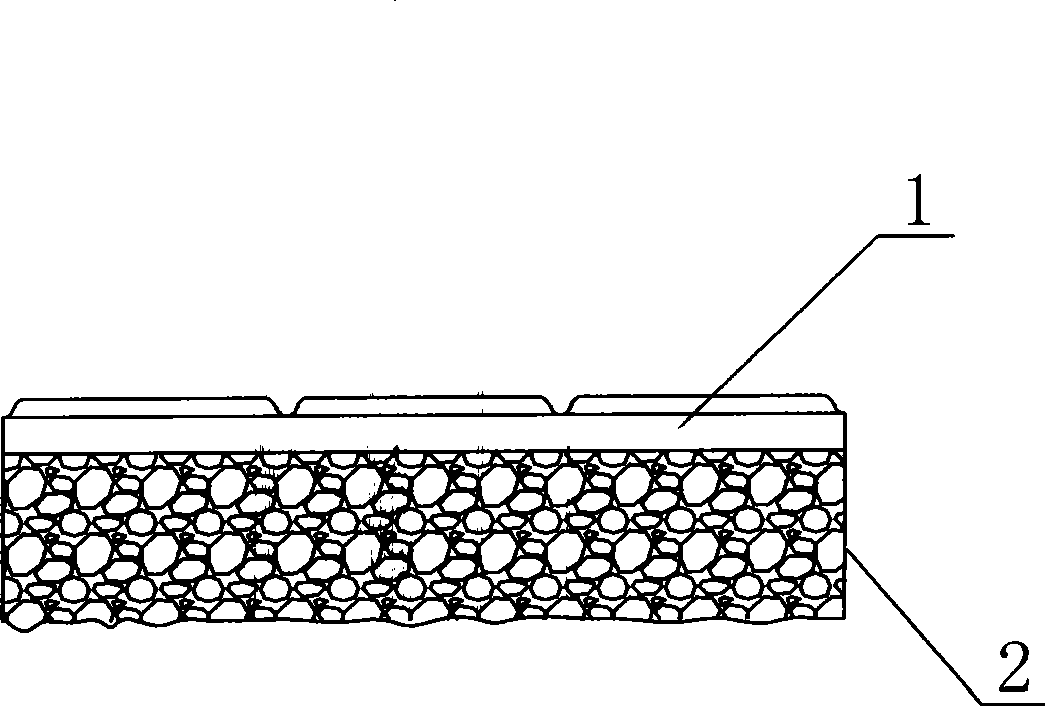

[0027] An inverted roof thermal insulation light board, which is a double-layer composite structure composed of a poured mixed mortar surface layer 1 with a thickness of 8-20mm and a lightweight granular material bottom layer 2 with a thickness of 30-100mm. The material of the surface layer 1 is composed of cement, fly ash, coarse sand, additives and water. The weight and addition ratio of cement, fly ash and coarse sand are: 24-28 parts of cement, 3-5 parts of fly ash , 65-75 parts of coarse sand, the addition of additives is 1.6% of the total weight of cement and fly ash, and the addition of water is 50% of the total weight of cement, fly ash and coarse sand; The material of the bottom layer 2 is composed of cementing material, granular material, water reducer, foaming agent, waterproof liquid and water. The parts by weight and addition ratio of each material are: 50-60 parts of cementing material, 1-2 parts of granular material, 0.2-0.5 parts of water reducing agent, 0.015-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com