Epoxy resin, phenol resin, their production methods, epoxy resin composition and cured product

A technology of epoxy resin and phenolic resin, which is applied in the field of epoxy resin, phenolic resin, the manufacture of these, epoxy resin composition and cured product, and can solve the problems of difficult formation of resin composition for transfer molding, low hygroscopicity, viscous Insufficient consideration of directness and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

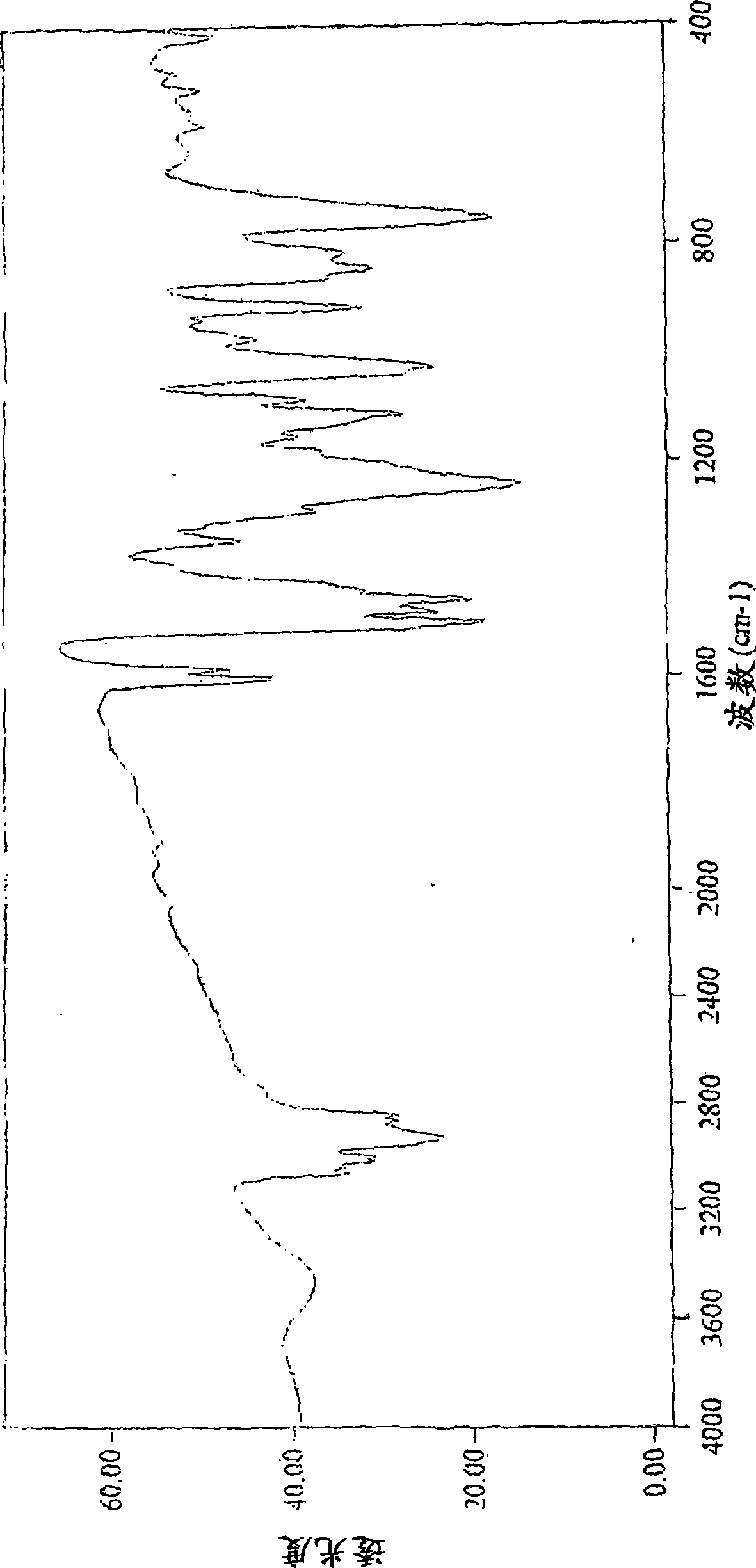

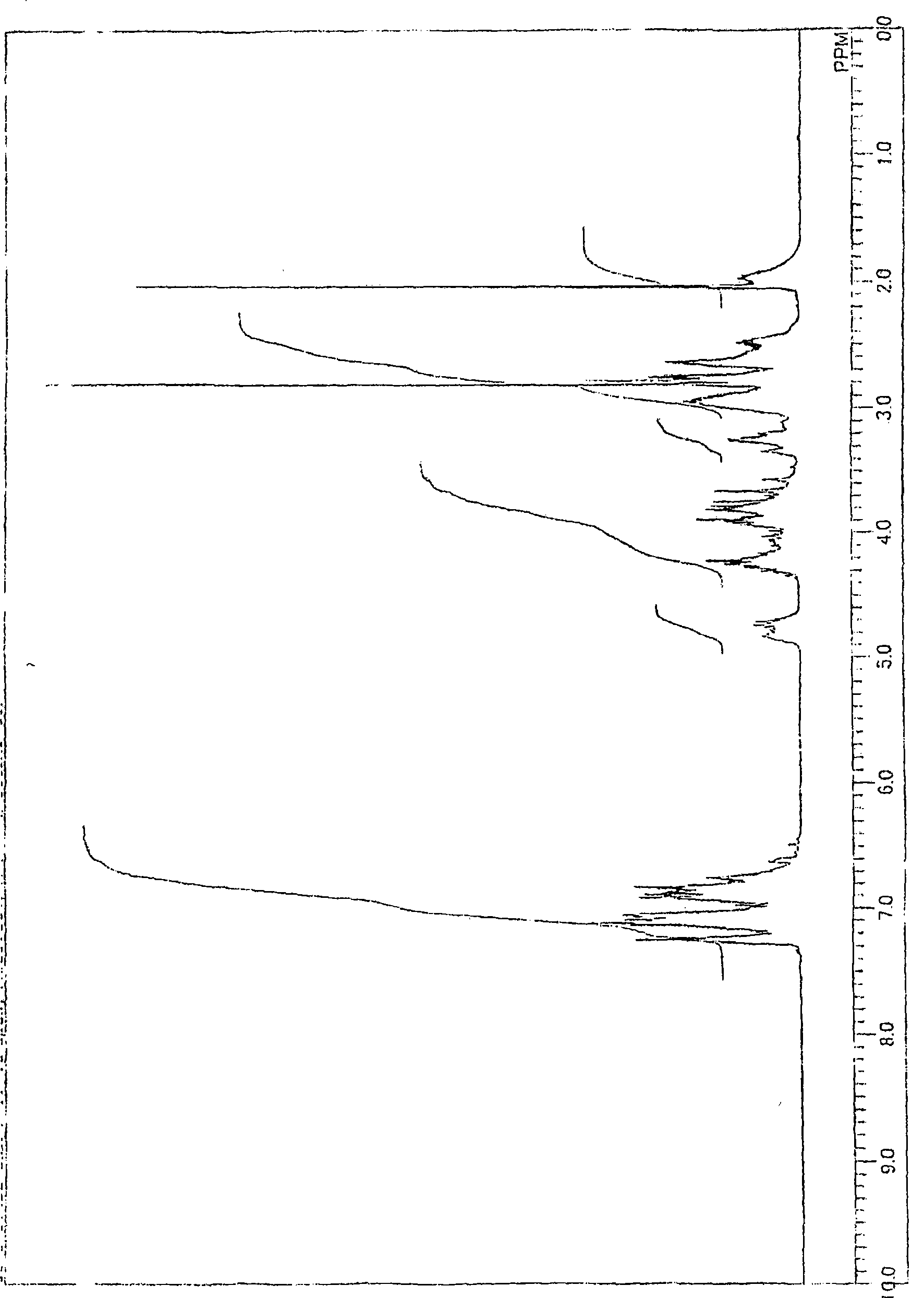

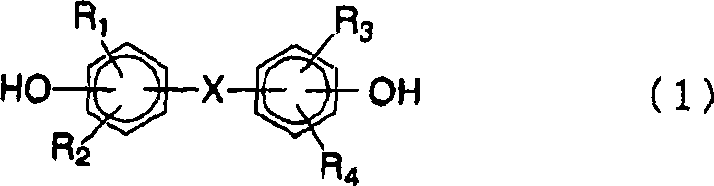

[0062] 200 g (1.0 mol) of bisphenol F (manufactured by Honshu Chemical Co., Ltd., 4,4' body (31%), 2,4' body (49%), 2,2' body (20%)) was charged in a 1L flask, and the temperature was raised. to 175°C. After melting, 0.1 g of p-toluenesulfonic acid was added with stirring, and 232 g (2.0 moles) of indene was added dropwise at 175° C. over about 3 hours. The reaction was continued for another 3 hours under reflux. Then, low boiling point components were removed under reduced pressure to obtain 413 g of an indene-added phenolic resin (phenolic resin A). The OH equivalent is 216 g / eq., the softening point is 78°C, and the melt viscosity at 150°C is 0.06 Pa·s.

Embodiment 2

[0064] 200 g (1.0 mol) of bisphenol F was charged in a 1 L flask, and the temperature was raised to 175°C. After melting, 0.15 g of p-toluenesulfonic acid was added with stirring, and 348 g (3.0 moles) of indene was added dropwise at 175° C. over about 3 hours. Then, low boiling point components were removed under reduced pressure to obtain 527 g of an indene-added phenolic resin (phenolic resin B). The OH equivalent is 274 g / eq., the softening point is 86°C, and the melt viscosity at 150°C is 0.15 Pa·s.

Embodiment 3

[0066] 200 g (1.0 mol) of bisphenol F was charged in a 1 L flask, and the temperature was raised to 180°C. After melting, 0.04 g of p-toluenesulfonic acid was added while stirring, and 304 g (2.0 moles) of acenaphthylene was added dropwise at 180° C. over about 3 hours. Then, the temperature was raised to 200° C. under reduced pressure, and low boiling point components were removed to obtain 491 g of acenaphthylene-added phenolic resin (phenolic resin C). The OH equivalent is 252 g / eq., the softening point is 99°C, and the melt viscosity at 150°C is 0.59 Pa·s.

[0067] In addition, the reaction rate of indene in Examples 1-3 was about 100%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com