Method for preparing high efficiency concrete water reducing agent by using industrial acenaphthylene

The technology of a concrete water-reducing agent and industrial acenaphthene is applied in the field of preparation of new concrete water-reducing agents, which can solve the problem of high manufacturing cost of high-quality water-reducing agents, and achieve the effects of reducing production costs and improving flexural strength and compressive strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

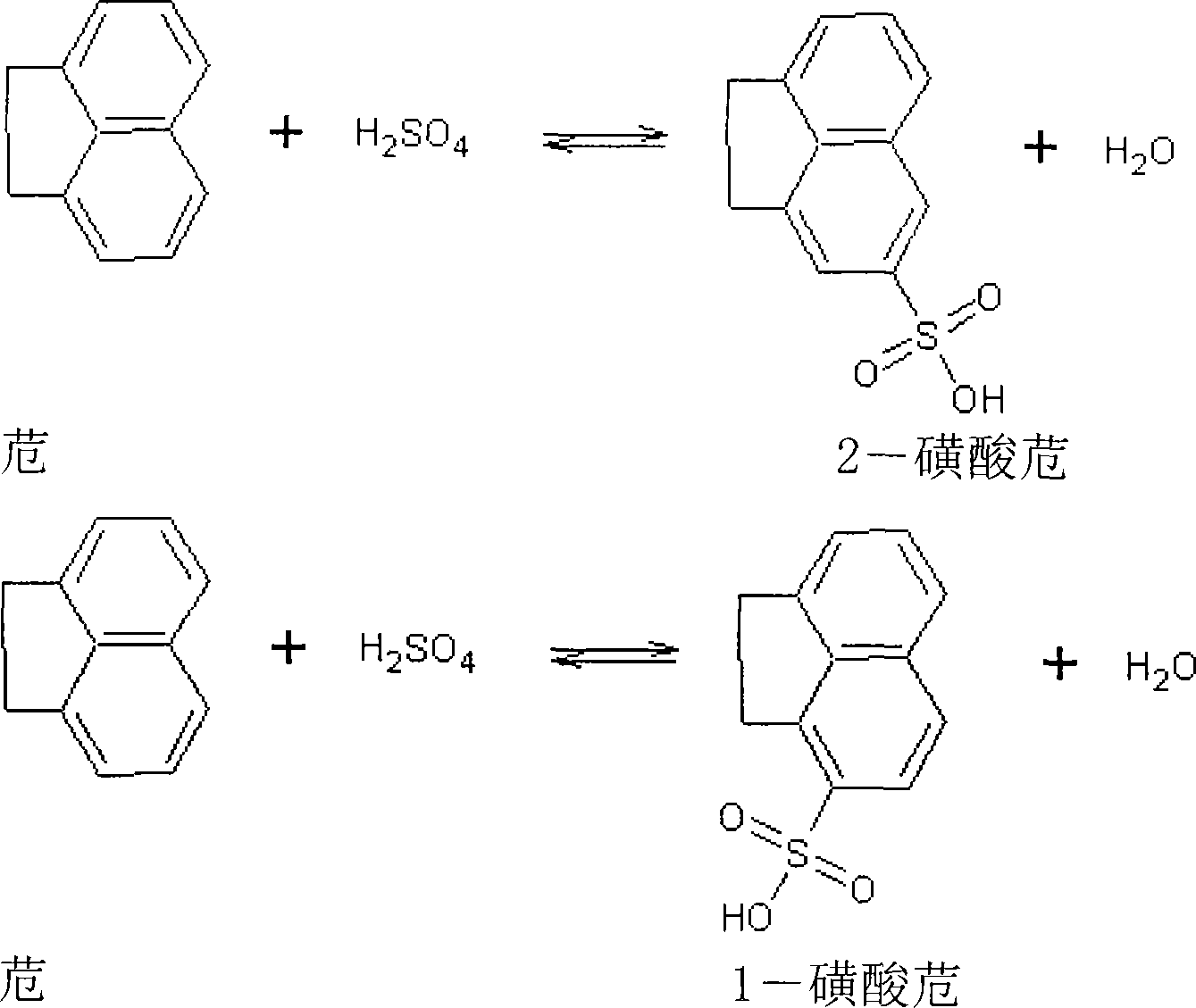

[0012] (1), sulfonation reaction: drop into 154g industrial acenaphthene in a 500ml three-necked flask, and heat to 110°C; add 93g of 98% concentrated sulfuric acid dropwise, and finish adding dropwise in 1 hour, and keep warm at 80°C for 4 hours to carry out sulfonation reaction, Generate 2-sulfonic acid acenaphthylene and 1-sulfonic acid acenaphthylene. The sulfonation reaction formula is as follows:

[0013]

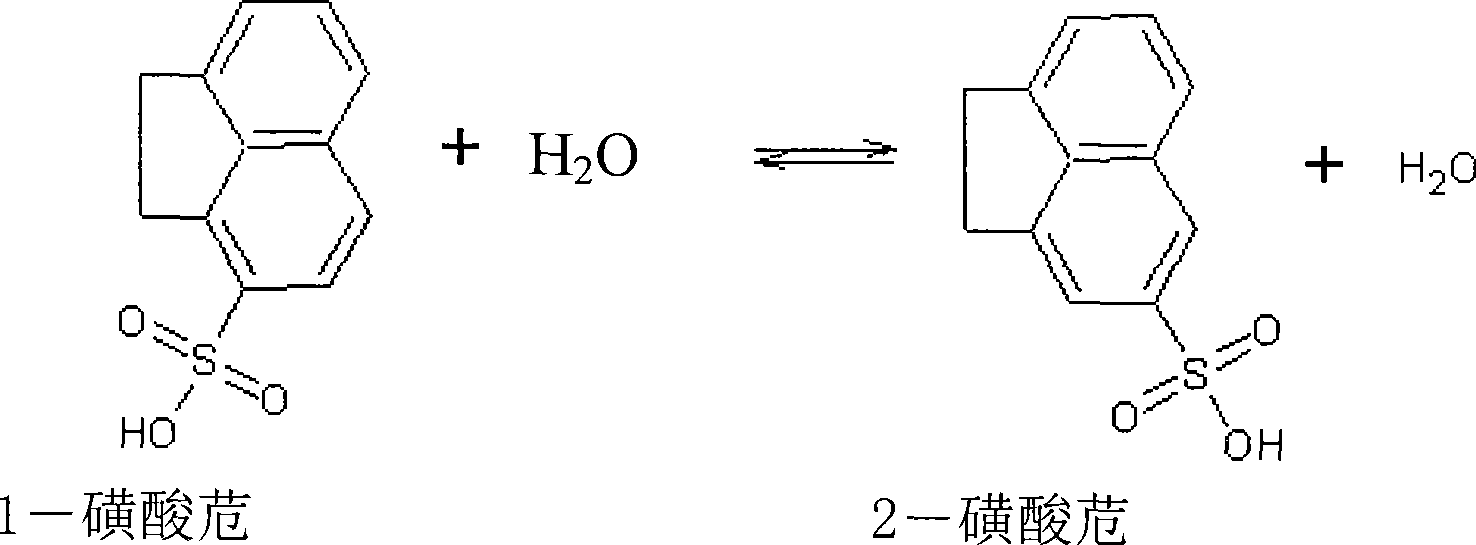

[0014] (2), hydrolysis reaction: then lower the temperature, add water, the acidity is 7.1%, hydrolyze for half an hour, 1-acenaphthylene sulfonate is converted into 2-acenaphthylene sulfonate. The hydrolysis reaction formula is as follows:

[0015]

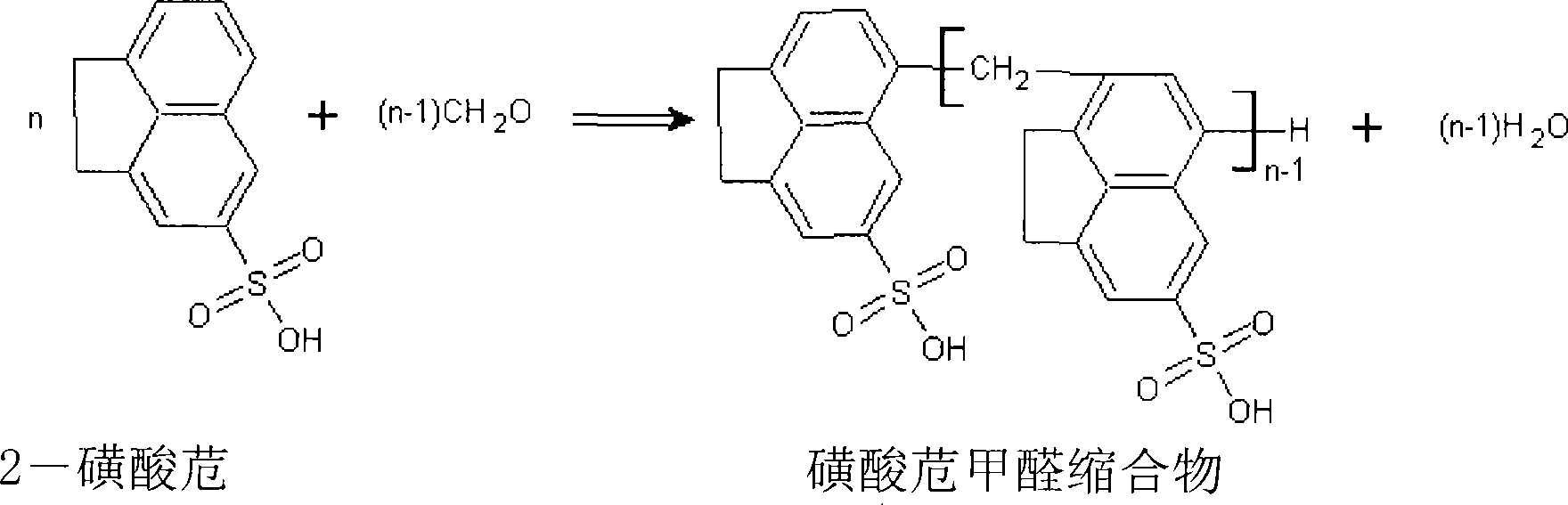

[0016] (3), condensation reaction: keep temperature 70 ℃, dropwise add 37% formaldehyde 60g, dropwise finish in 1~1.5 hours, and keep warm for 2.5 hours, generate sulfonic acid acenaphthylene formaldehyde condensate. The condensation reaction formula is as follows:

[0017]

[0018] (4) Neutralization reactio...

Embodiment 2

[0022] (1), sulfonation reaction: drop into 154g industrial acenaphthene in a 500ml three-necked flask, and heat to 85°C; add 198g 98% concentrated sulfuric acid dropwise, finish dropping in 1 hour, and keep warm at 90°C for 2 hours;

[0023] (2), hydrolysis reaction: then cool down to 85°C and add water to make the acidity at 19.2%, and hydrolyze for half an hour;

[0024] (3), condensation reaction: maintain temperature at 55 ℃ and drop 110g of 37% formaldehyde, dropwise finish in 1.5 hours, and keep warm for 5 hours;

[0025] (4), neutralization reaction: finally add 30% sodium hydroxide solution 100g, then adjust the pH value to 7.4 with calcium hydroxide solution, filter with a filter screen, remove sediment, and obtain powder after dehydration, drying and pulverization of the liquid High-efficiency concrete superplasticizer.

[0026] The powdery high-efficiency concrete water reducer prepared according to the above method is dissolved in water and the specific gravity i...

Embodiment 3

[0028] (1), sulfonation reaction: drop into 154g industrial acenaphthene in a 500ml three-necked flask, heat to 80°C; add 163g98% concentrated sulfuric acid dropwise, dropwise in 1 to 1.5 hours, and keep warm at 150°C for 5 hours;

[0029] (2), hydrolysis reaction: then cool down to 130 ℃ and add water, the acidity is 13.6%, hydrolysis for 40 minutes;

[0030] (3), condensation reaction: maintain the temperature at 105 ℃ and drop 100 g of 37% formaldehyde, drop it in 2 hours, and keep it warm for 4 hours;

[0031] (4) Neutralization reaction: Finally, add potassium hydroxide solution to adjust the pH value to 8, and finally cool to obtain a liquid high-efficiency concrete superplasticizer.

[0032] According to the liquid high-efficiency concrete water reducer prepared by the above method, the specific gravity is adjusted to 1.200, and when the dosage is 1.6%, the fluidity of the cement slurry reaches 241mm. When the dosage in the mortar is 1.8%, the water reducing rate can r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com