Method for producing poly-lactic acid products

A production method, polylactic acid technology, applied in the field of polylactic acid production, can solve the problems of reduced flexibility, production knocking, PLA difficulties, etc., and achieve the effect of solving the service life problem, increasing the service life, and cheap price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

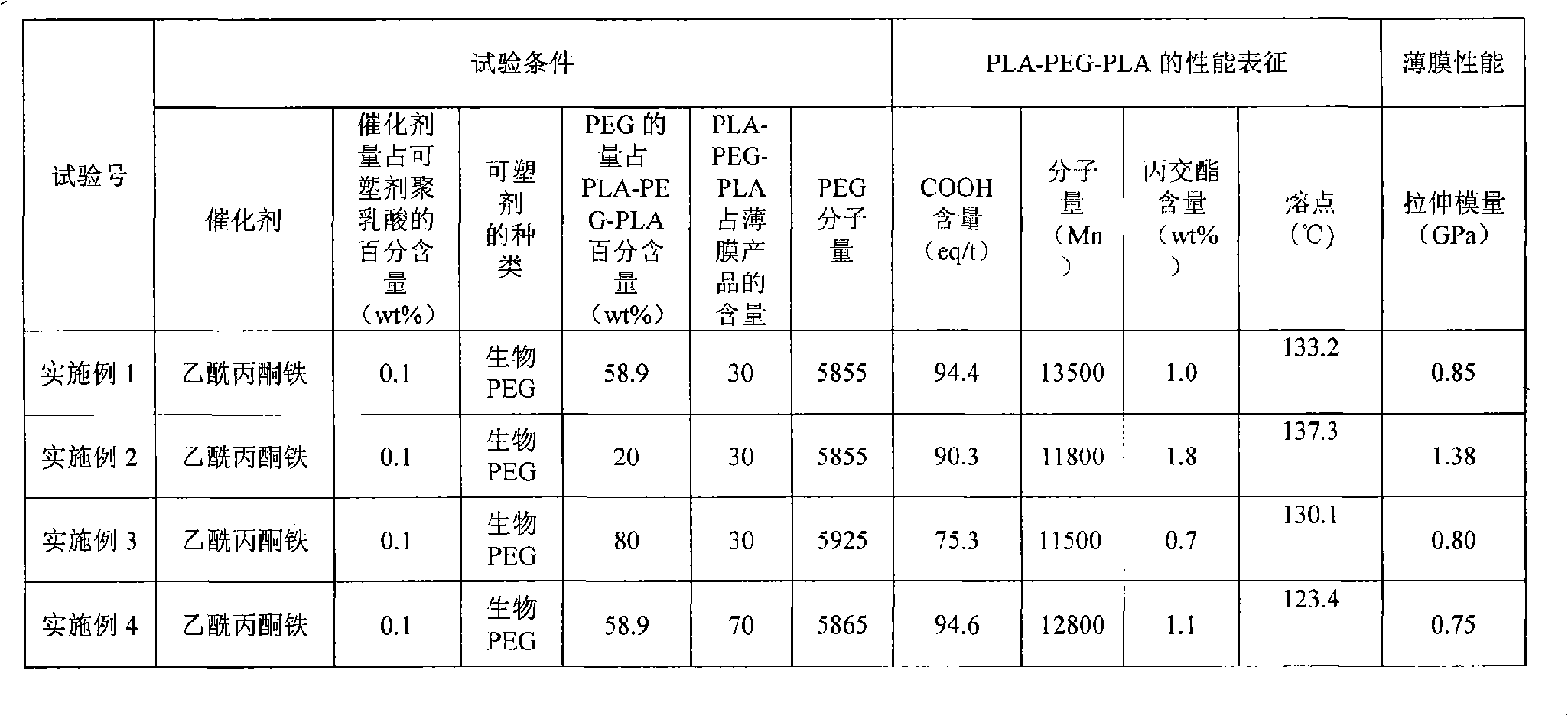

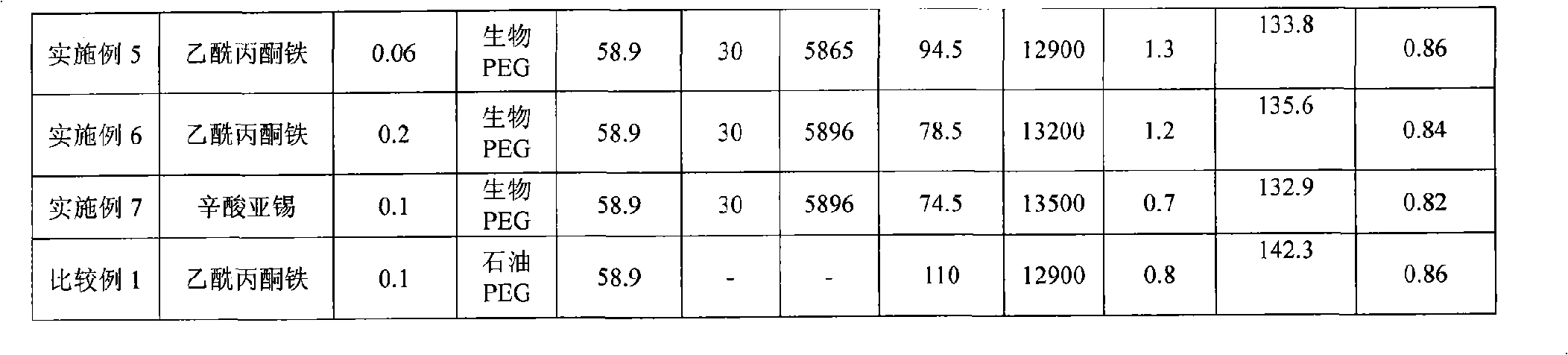

Examples

Embodiment 1

[0025] Add 58.9g of bio-PEG6000 into the cleaned test tube with a spout, then install the overlapping head, put it in a silicone oil tank at 160°C, connect and stir, adjust the stirring speed to 17rpm, and use nitrogen gas before dissolving the bio-PEG6000 Replace the reaction system repeatedly, about 3 times, then react under full vacuum for 30 minutes (the degree of vacuum is about 300Pa). Return to normal pressure and add the prepared 41.1g lactide (purac company in the Netherlands), adjust the stirring speed to 29rpm, and replace the reaction system with nitrogen for about 3 rounds, and after 10 minutes of reaction with nitrogen, add the catalyst iron acetylacetonate (Shanghai Sanai Si Reagent Co., Ltd.) (0.1mol / ml, 2.5ml), toluene (Jiangsu Jincheng Reagent Factory) as the solvent), continue to replace for 3 rounds, and then react under nitrogen for 2 hours, then add the deactivator phosphoric acid crystals (SIGMA -ALDRICH) (0.1mol / ml, 0.09ml) was reacted under nitrogen fo...

Embodiment 2

[0029] The experimental process and conditions were the same as in Example 1, the amount of PEG was 20g, and the amount of lactide was 80g.

Embodiment 3

[0031] The experimental process and conditions were the same as in Example 1, the amount of PEG was 80g, and the amount of lactide was 20g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com