Hydro-thermal treatment method capable of improving performance of chalcogen semiconductor film

A hydrothermal treatment, semiconductor technology, applied in semiconductor/solid-state device manufacturing, liquid chemical plating, coating, etc., can solve the problems of expensive, poor adhesion of chemical film formation, complex process and so on

Inactive Publication Date: 2010-12-01

DALIAN UNIV OF TECH

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, due to the disadvantages of poor adhesion, inhomogeneity, and imperfect crystal form in chemical film formation, the deposited film usually needs to be heat-treated at high temperature (above 400°C) in H2S, H2Se, vacuum or inert atmosphere. Requires expensive vacuum or atmosphere treatment equipment, and the process is complex and easy to pollute the environment

There is no related invention patent report

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

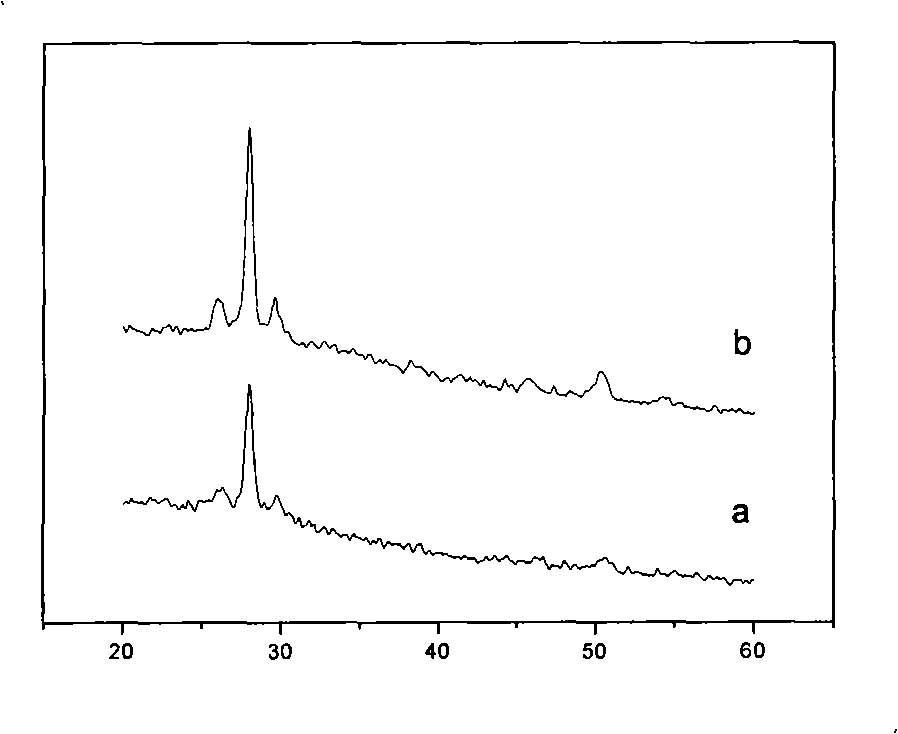

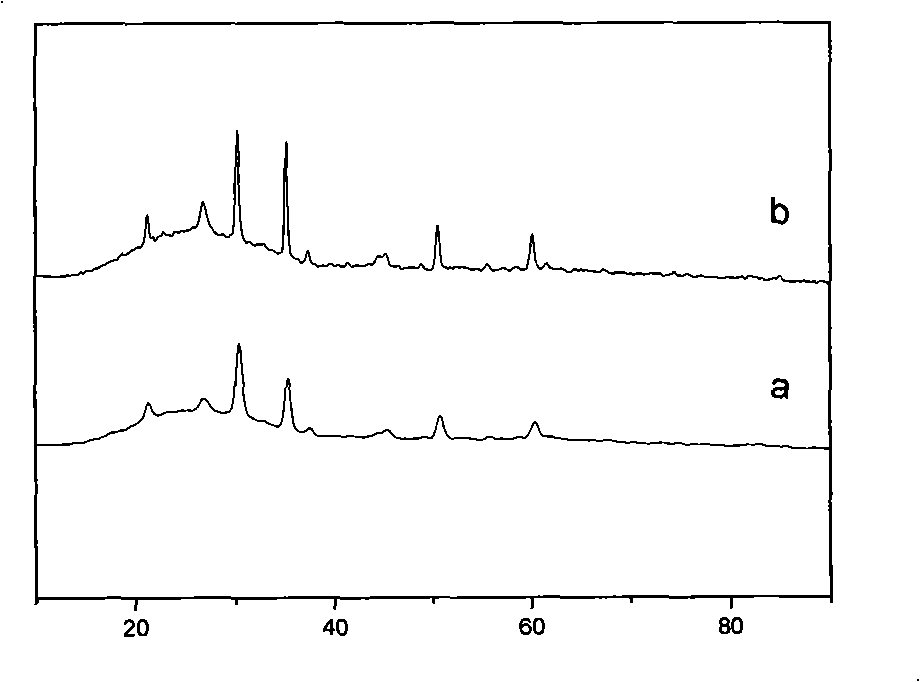

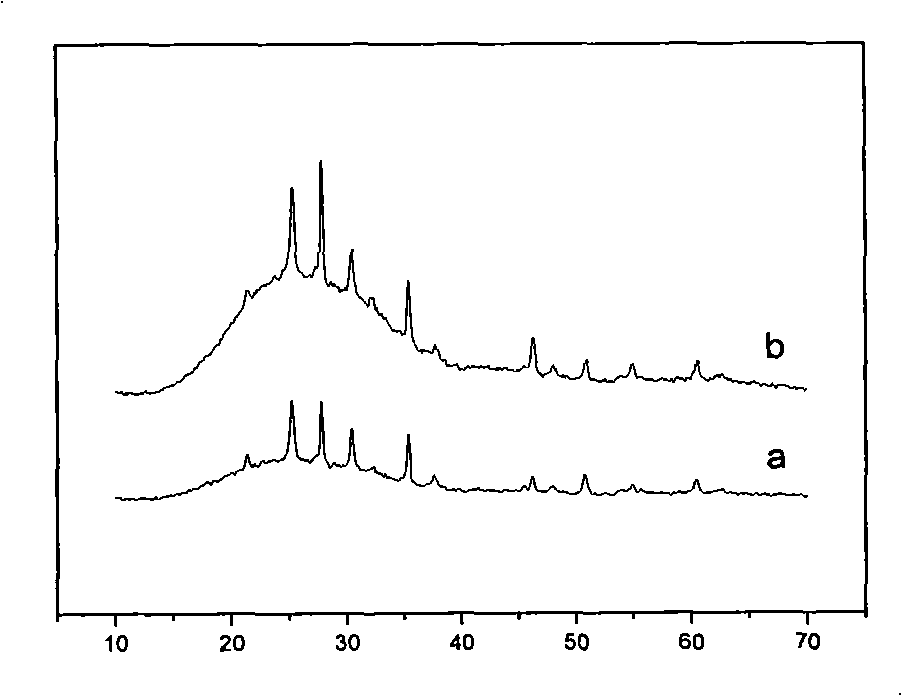

The invention relates to a treatment method capable of improving the performance of a chalcogen semiconductor film prepared by a soft chemical method, in particular to a treatment method of carrying out hydro-thermal treatment in a sulfide or ion aqueous solution to improve the performance of the chalcogen semiconductor film prepared by the soft chemical method. The method comprises the followingsteps: firstly, preparing the 0.01M to 0.3M sulfide or ion aqueous solution; then, pouring the solution into a hydro-thermal reactor and putting the chalcogen semiconductor film precipitated by soft chemical methods such as a chemical-bath method, continuous ion sheath absorption reaction method or an electric-precipitation method into the solution; and finally, carrying out the hydro-thermal treatment to the chalcogen semiconductor film at 160 DEG C to 240 DEG C. Compared with the prior method of thermally treating the film in an H2S atmosphere, an H2Se atmosphere, an inertia atmosphere or vacuum at a high temperature above 400 DEG C, the invention has low reaction temperature, little pollution and simple equipment, is suitable for various substrate surfaces and can remarkably improve the performance of the film, such as the degree of crystallinity, the photoelectricity, and the like.

Description

A hydrothermal treatment method that can improve the properties of chalcogenide semiconductor thin films technical field The present invention relates to a kind of heat treatment method that can improve film property, relate to a kind of treatment method that can improve the property of chalcogenide film prepared by softening chemical method, especially relate to a kind of by carrying out hydrothermal treatment in sulfur or selenium ion aqueous solution to improve softness. Treatment methods for the properties of chalcogenide thin films prepared by chemical methods. Background technique Chalcogenide semiconductor thin film materials represented by CdS, CuInS2, and CuInSe2 have important applications in thin-film solar cells, photoconductors, and sensors, especially in the field of extremely thin absorbing layer ETA (Extremely ThinAbsorber) solar cells, due to their unique high absorption coefficient And chemical stability, it can be used as an efficient adsorption layer to...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H01L21/208C23C18/02

Inventor 石勇薛方红李春艳薛冬峰王立秋

Owner DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com