Method for processing waste gas from the production of viscose chemical fiber

A technology for viscose chemical fiber and waste gas treatment, which is applied in chemical instruments and methods, separation methods, and separation of dispersed particles, etc. It can solve the problems of poor economic benefits, large investment, and small investment in adsorption methods, and achieve low cost and reduced risk factor , cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

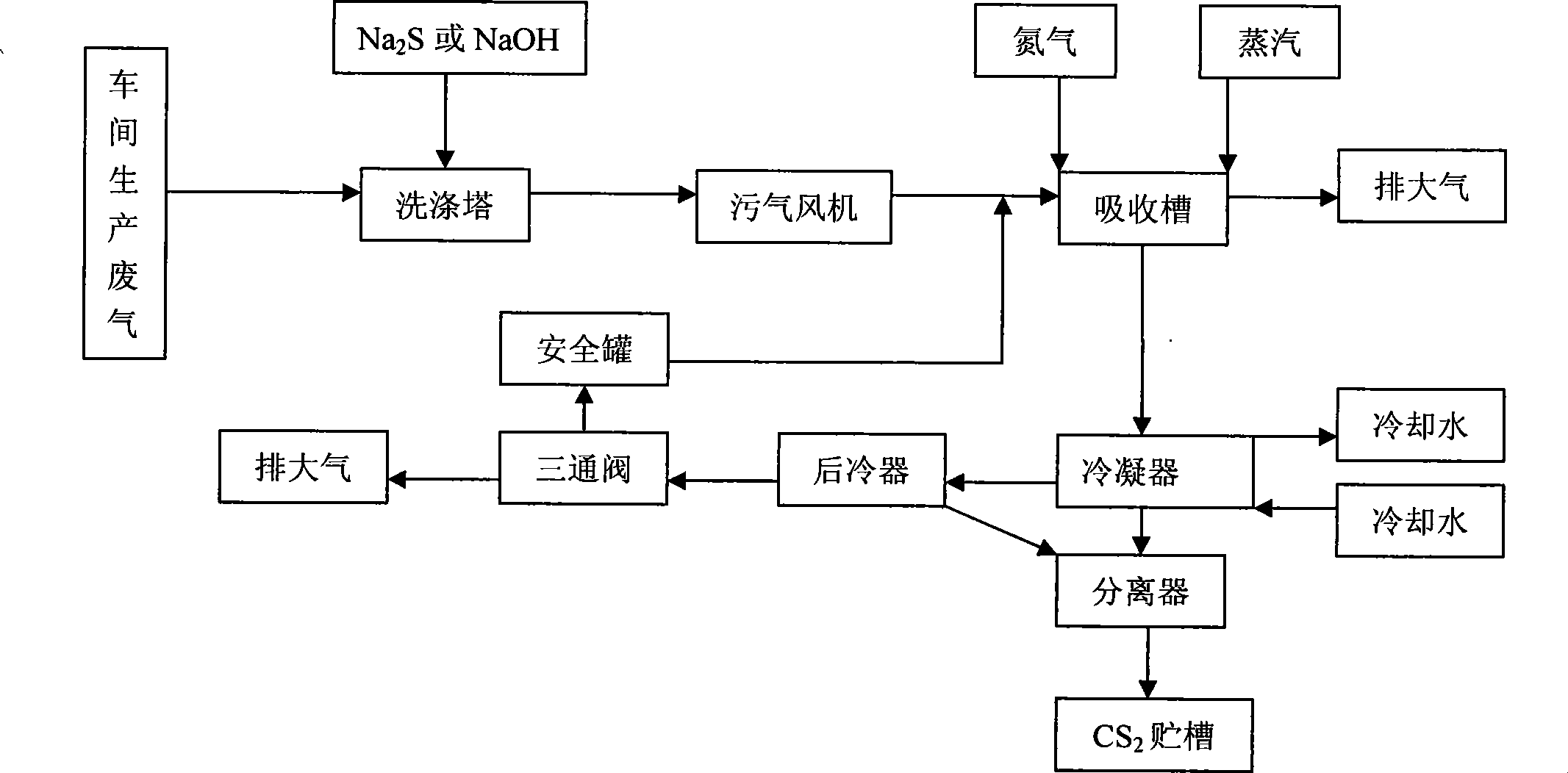

[0022] (1) The exhaust gas produced by Xin'ao raw material, spinning and acid production lines is sent to the washing tower through the fan;

[0023] (2) Prepare sodium hydrosulfide by rinsing: add 205-200g / L NaOH in the washing tower for three rinsing, reaction equation: NaOH+H 2 S→NaHS+H 2 O, the gas after washing is cooled;

[0024] (3) Absorption: The gas after cooling is mainly CS 2 , sent to the adsorption tank for adsorption regeneration, the adsorption material used is activated carbon, the remaining gas after adsorption is discharged into the atmosphere, and then the steam flow is introduced to desorb the activated carbon;

[0025] (4) Condensation: CS after desorption 2 The gas is sent to the condenser to condense;

[0026] (5) Recovery: the liquid CS after condensation 2 and water into the separator, through which the liquid CS 2 and water separation, where CS 2 Liquid is sent to CS 2 The storage tank, the water is drained, and the remaining uncondensed mixe...

Embodiment 2

[0031] (1) The exhaust gas produced by the first and second phase spinning machines is sent to the washing tower through the fan;

[0032] (2) Prepare sodium hydrosulfide by rinsing: add 200-280g / L Na in the washing tower 2 S is washed three times, the reaction equation: Na 2 S+H 2 S→NaHS, to cool down the washed gas;

[0033] (3) Absorption: The gas after cooling is mainly CS 2 , sent to the adsorption tank for adsorption regeneration, the adsorption material used is activated carbon, the remaining gas after adsorption is discharged into the atmosphere, and then the steam flow is introduced to desorb the activated carbon;

[0034] (4) Condensation: CS after desorption 2 The gas is sent to the condenser to condense;

[0035] (5) Recovery: the liquid CS after condensation 2 and water into the separator, through which the liquid CS 2 and water separation, where CS 2 Liquid is sent to CS 2 The storage tank, the water is drained, and the remaining uncondensed mixed gas is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com