Production process of artistic bamboo chopstick

A production process, the technology of bamboo chopsticks, applied in the direction of manufacturing tools, wood processing equipment, etc., can solve the problems of involving a large number of manpower operations, bamboo strips cannot be punched into bamboo blanks, and insufficient resource utilization, so as to improve resource utilization and facilitate The effect of reducing processing and production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

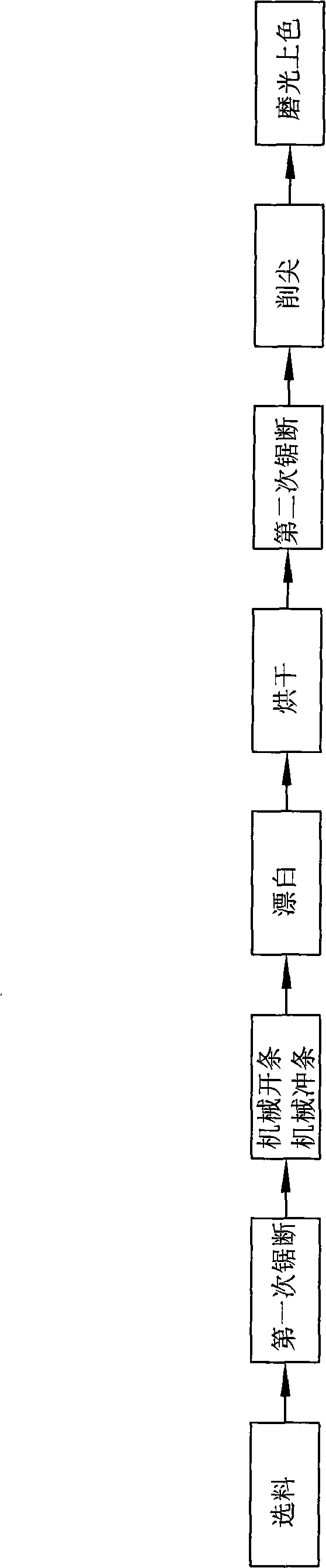

[0019] Such as figure 1 As shown, the first step of the production process of bamboo chopsticks is material selection, the selected bamboo can be five to six inches in size, so the requirements for raw materials are very low, which is conducive to expanding the utilization rate of bamboo resources; second The first step is to use a cutting machine to saw the bamboo into sections of bamboo tubes according to the needs. The length of the bamboo tubes can be 60 cm, and the 60 cm bamboo tubes have bamboo joints; in the third step, these bamboo tubes with bamboo joints are processed by the punching machine Open strips, there are no cracks and cracks on the bamboo strips with bamboo joints obtained from the strip operation, and then the bamboo strips with bamboo joints are punched into the shape of bamboo blanks with a wire drawing machine; after the fourth step of bleaching and the fifth step After drying in the first step, the bamboo strips with bamboo joints are sawn into rough-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com