Method for preparing high performance Ti2AIC ceramic powder

A ceramic powder, high-performance technology, applied in the field of preparation of high-performance Ti2AlC ceramic powder, can solve the problems of complex process, harsh synthesis conditions, limited promotion and application, etc., achieve high sintering activity, easy industrialization, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

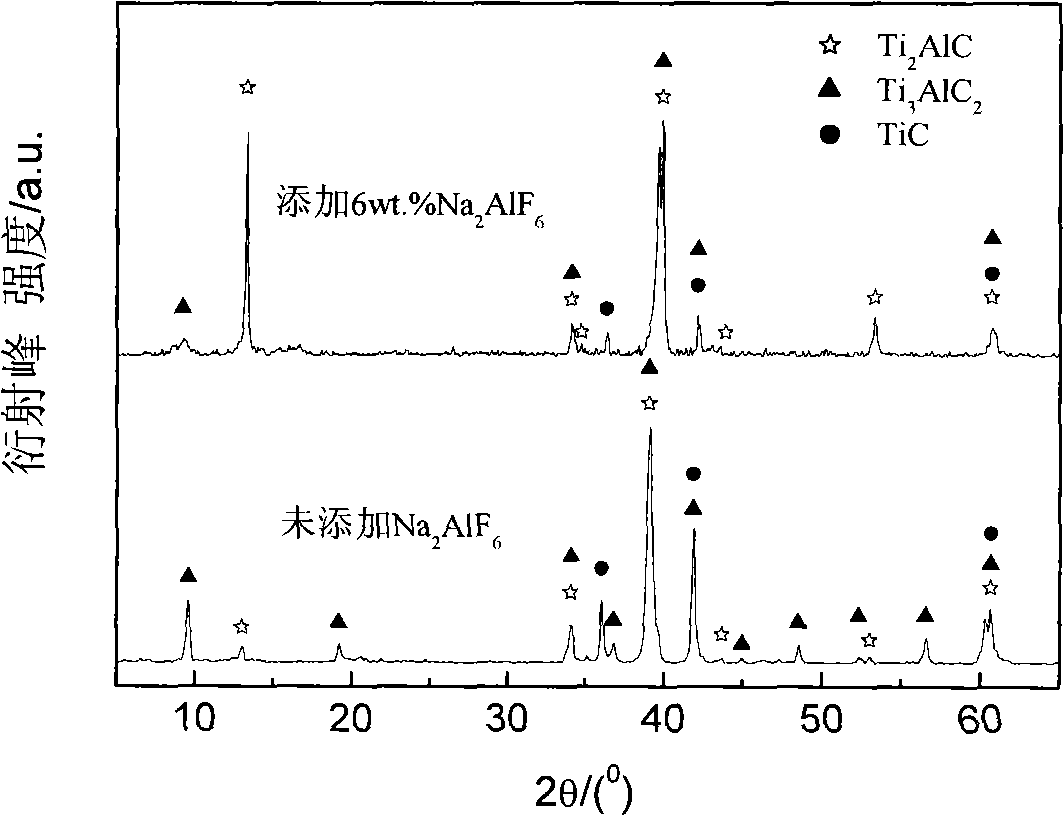

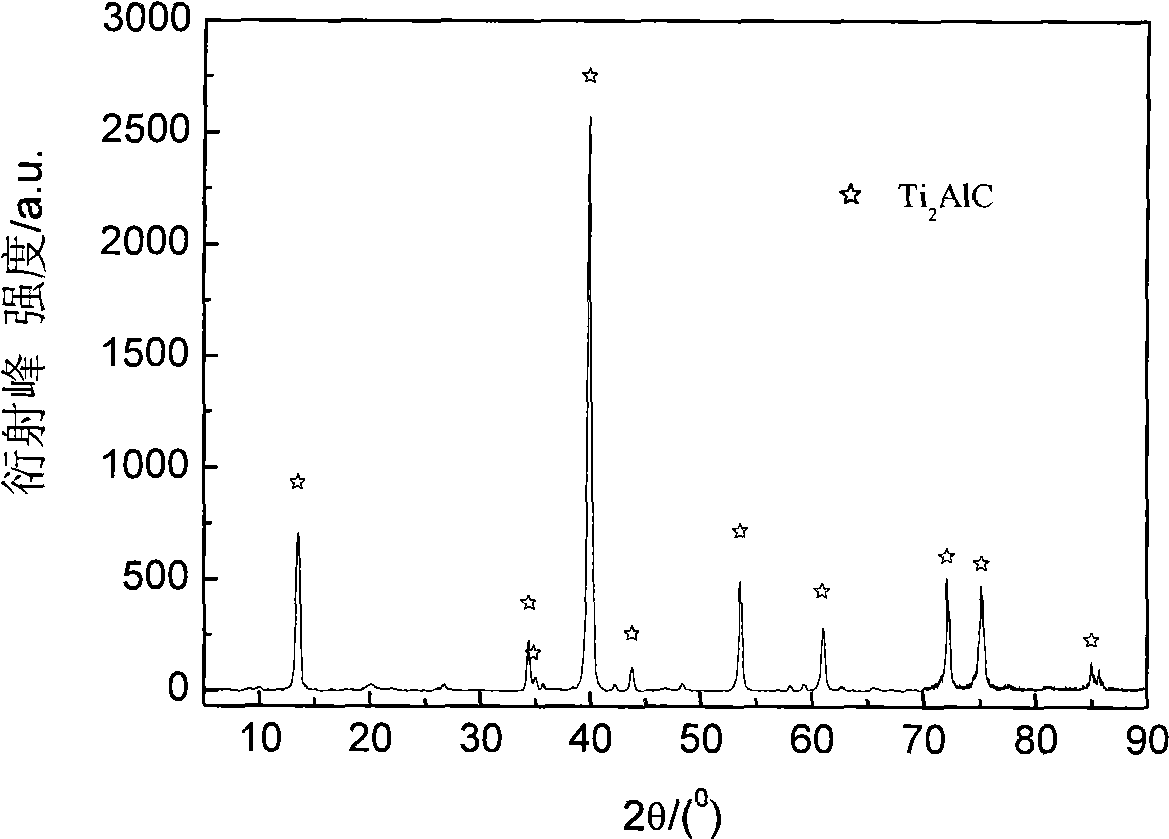

Embodiment 1

[0019] The raw material powder is compounded according to the molar ratio Ti:Al:C=2:1:1, and the additive cryolite Na 2 AlF 6 The addition amount is 6wt.% of the total mass of calculated raw material Ti powder, Al powder and C powder, wherein Na 2 AlF 6 The quality of Al in should be included in the quality of Al in the total ratio of raw materials. Grind on a planetary ball mill for 8 hours with anhydrous ethanol as the medium, dry at 70°C or naturally, ignite the reactants with a tungsten coil under the protection of argon, and cool naturally, the obtained product is Ti 2 AlC powder.

[0020] Additive cryolite Na2AlF based on the total mass of calculated raw material Ti powder, Al powder and C powder 6 The addition amount of Ti is changed to 0.1wt.% and 25wt.%, and other conditions remain unchanged, the resulting product is also Ti 2 AlC powder.

Embodiment 2

[0022] The raw material powder is compounded according to the molar ratio Ti:Al:C=2:1:1, and 10wt.% of the total mass of Ti powder, Al powder and C powder required for calculation is added to the self-made intermetallic compound TiAl by combustion 3 , additive cryolite Na 2 AlF 6 The amount of addition is 4wt.% of the total mass of raw materials Ti powder, Al powder and C powder, where Na 2 AlF 6 The quality of Al in should be included in the quality of Al in the total ratio of raw materials. Use anhydrous ethanol as the medium to ball mill on a planetary ball mill for 8 hours at 70°C or dry naturally, then ignite the reactants with a tungsten wire coil under the protection of argon, and cool naturally, the obtained product is Ti 2 AlC powder.

[0023] In this case the intermetallic compound TiAl 3 The addition amount was changed to 5wt.% and 20wt.% of the total mass of Ti powder, Al powder and C powder respectively, and the other conditions remained unchanged, and the ob...

Embodiment 3

[0025] The raw material powder is compounded according to the molar ratio Ti:Al:C=2:1:1, and 20wt.% of the total mass of Ti powder, Al powder and C powder required for calculation is added to burn and synthesize self-made TiC, and the additive cryolite Na 2 AlF 6 The addition amount is 2wt.% of the total mass of raw material Ti powder, Al powder and C powder according to the calculation, additive Na 2 AlF 6 The quality of Al in should be included in the quality of Al in the total ratio of raw materials. Use anhydrous ethanol as the medium to ball mill on a planetary ball mill for 8 hours at 70°C or dry naturally, then ignite the reactants with a tungsten wire loop under the protection of argon, and cool naturally, the product is Ti 2 AlC powder.

[0026] In this example, the addition amount of self-made TiC by combustion synthesis is changed to 5wt.% and 25wt.% of the total mass of Ti powder, Al powder and C powder required respectively, and the other conditions remain unch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com