Method for preparing calcium glycine

A technology of calcium glycinate and glycine is applied in the preparation of organic compounds, chemical instruments and methods, cyanide reaction preparation and other directions, and can solve the problems of low synthesis rate of finished products, complex process and high cost, and achieve low cost, simple preparation process, The effect of less moisture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

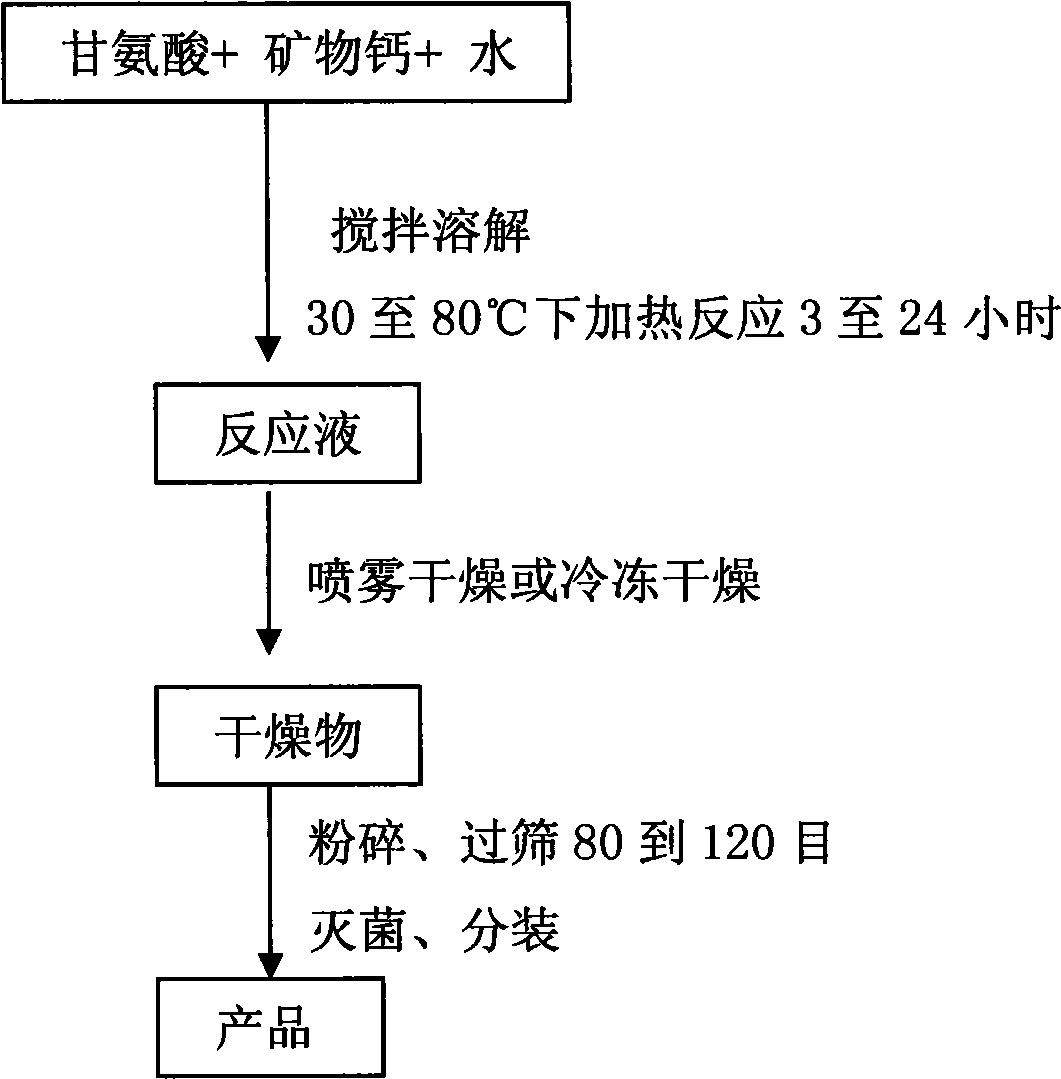

Method used

Image

Examples

Embodiment 1

[0020] Take 210kg of raw materials glycine, 90kg of calcium oxide and 700kg of water, mix them in a reactor, stir to fully dissolve, react at a temperature of 30°C for 5 hours, take the reaction solution, and let it stand for 8 hours; spray dry at 280°C, detect water parts, so that the moisture weight percentage is less than 9%, to obtain 210kg of dry matter, take the dry matter, pulverize, pass through a 100-mesh sieve, sterilize, and pack.

Embodiment 2

[0022] Take 300kg of raw materials glycine, 100kg of calcium oxide and 60kg of water, mix them in a reactor, stir to fully dissolve, react at 70°C for 12 hours, and let stand for 10 hours; take the reaction solution, spray dry it at 200°C, and detect water parts, make the moisture content by weight less than 7%, to obtain 270kg of dry matter, take the dry matter, pulverize, pass through 80 mesh sieve, sterilize, and pack separately.

Embodiment 3

[0024] Take 150kg of raw materials glycine, 80kg of calcium carbonate and 770kg of water, mix them in a reactor, stir to fully dissolve, react at a temperature of 55°C for 18 hours, and let stand for 12 hours; take the reaction solution, spray dry it at 250°C, and detect water parts, make the moisture content by weight less than 8%, to obtain 142kg of dry matter, take the dry matter, pulverize, pass through a 120 mesh sieve, sterilize, and repack.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com