Full flow electrohydraulic control system for construction machinery gear box

An electro-hydraulic control system and gearbox control technology, applied in mechanical equipment, control devices, transmission control and other directions, can solve the problems of limited promotion and popularization, increased maintenance costs, high processing and manufacturing requirements, and facilitate the expansion of buffer functions. , The effect of simplifying the structure of the valve and reducing the number of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

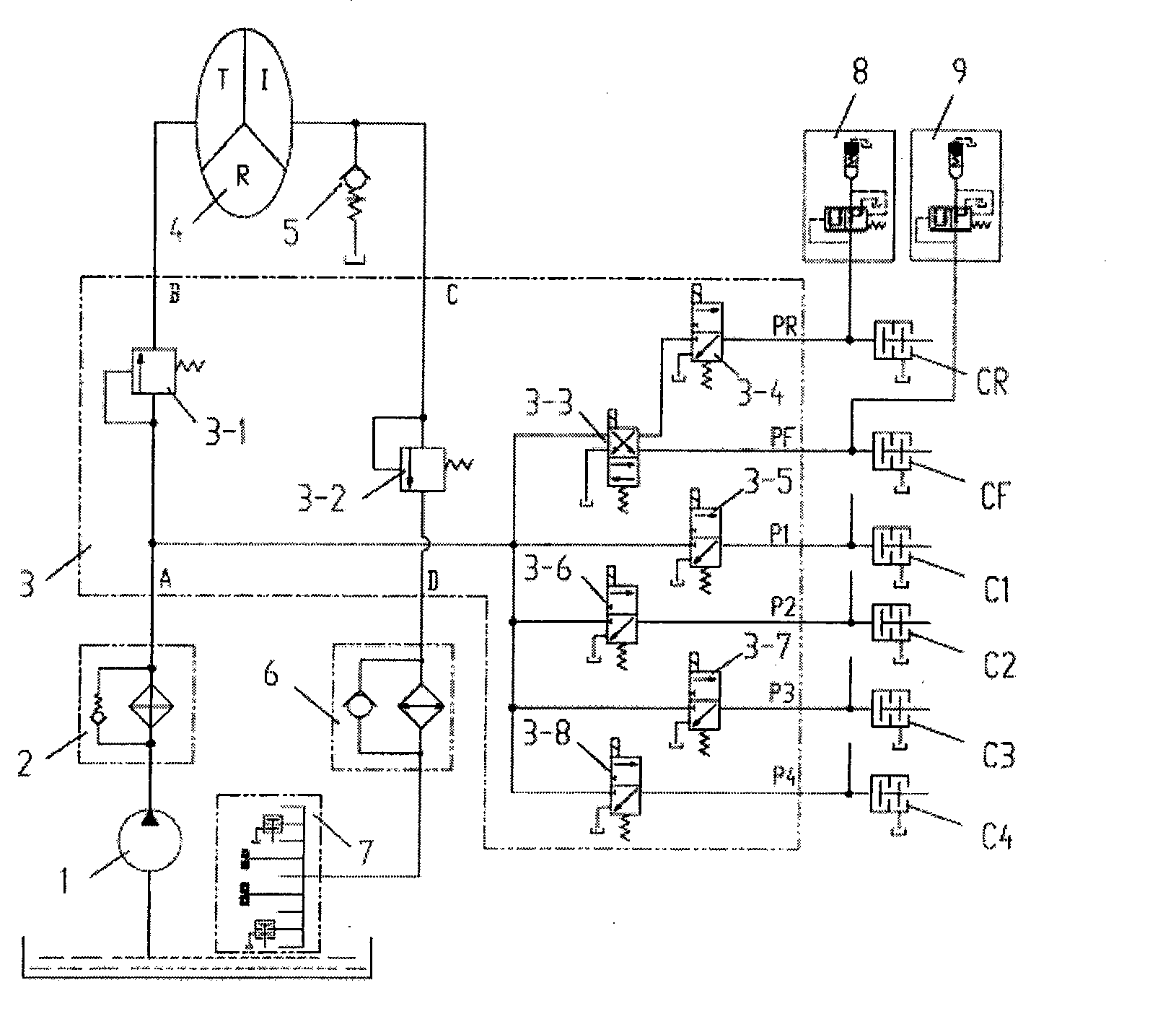

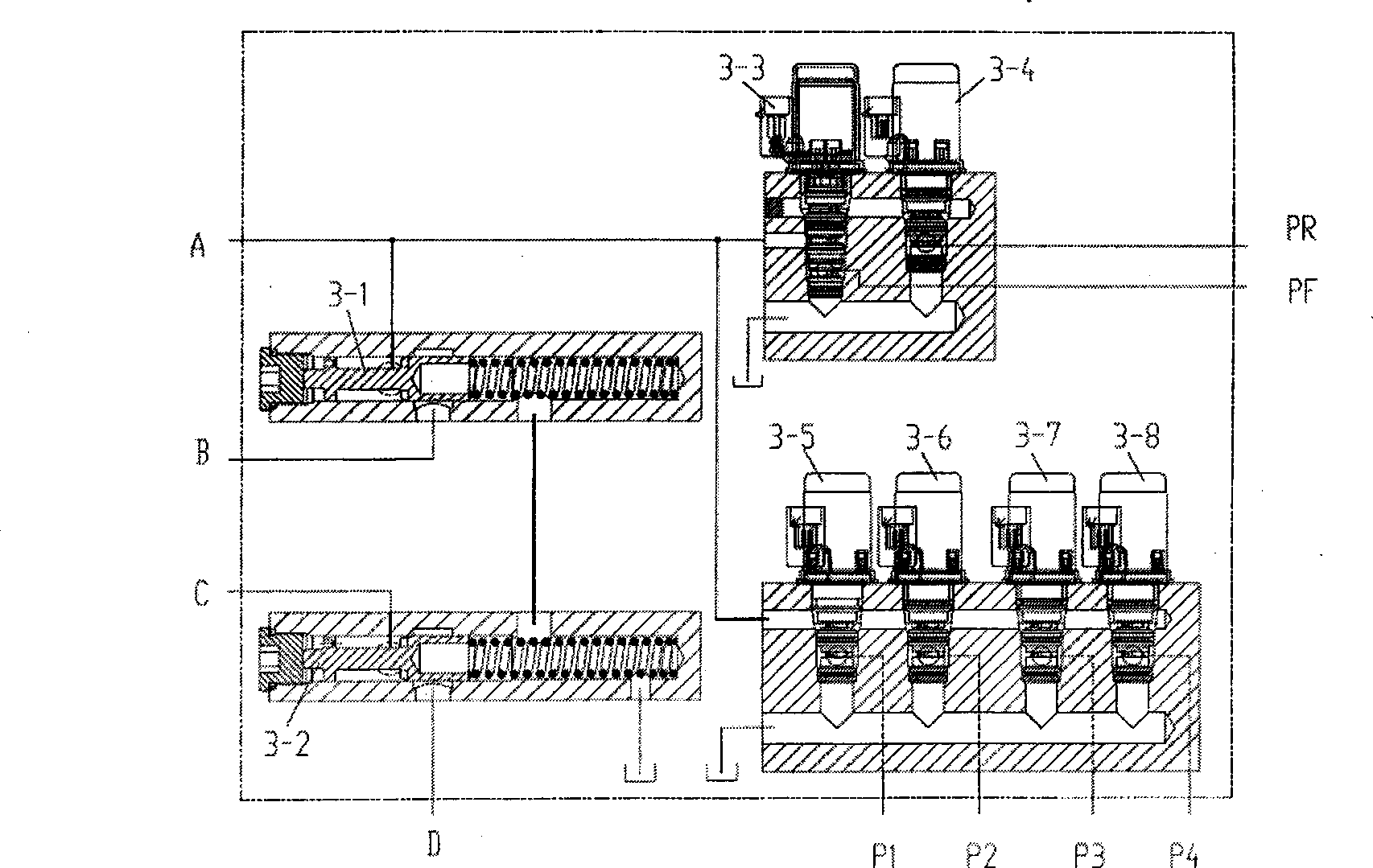

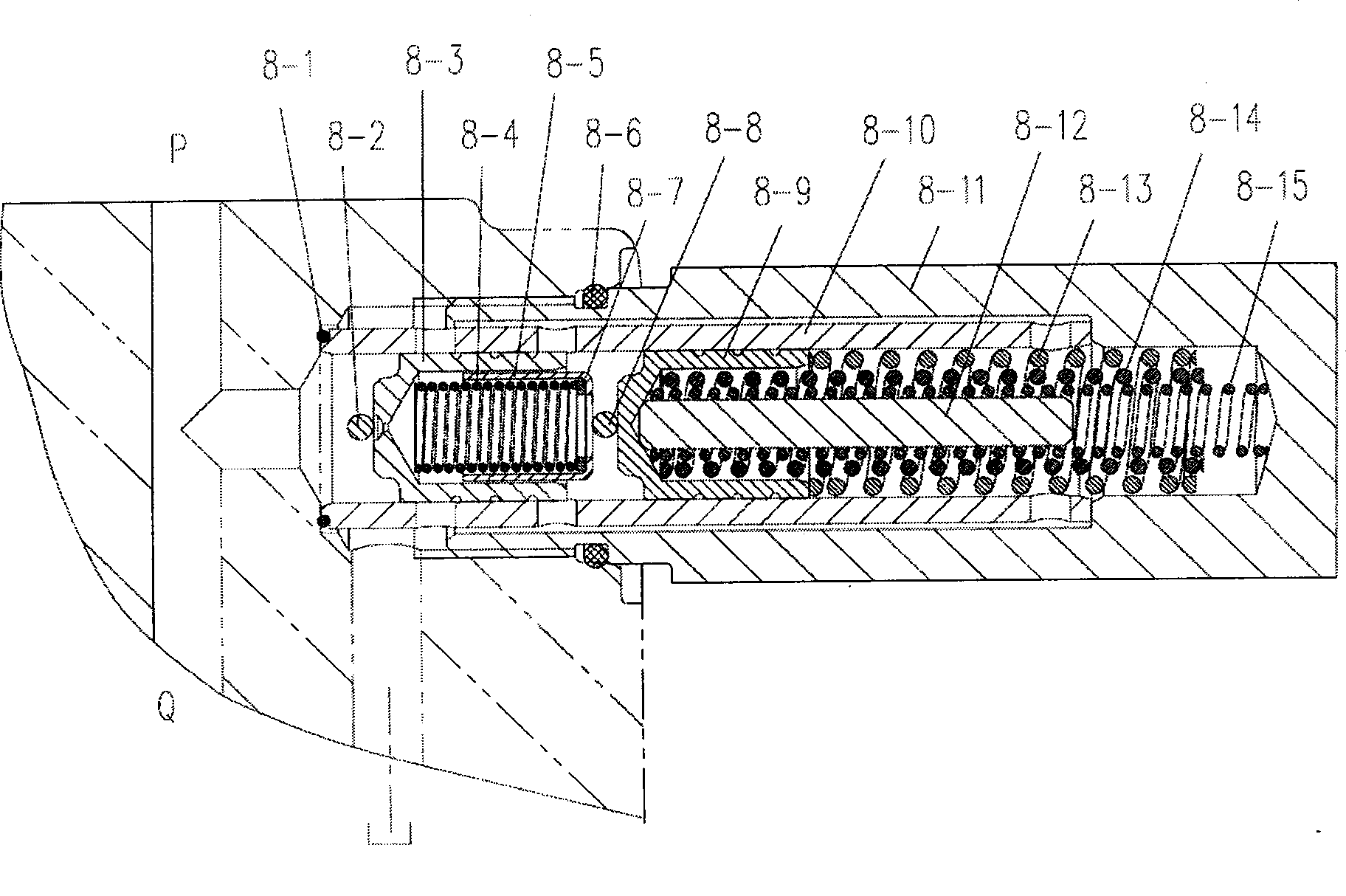

[0016] As shown in the figure: a full-flow electro-hydraulic control system for construction machinery gearboxes, which includes an electrical control part and a hydraulic control part. The electrical control part is mainly composed of a gearbox control handle, a computer control box, a speed sensor, and a wiring harness. Its hydraulic control part includes variable speed pump 1, filter 2, full-flow electro-hydraulic control valve 3, torque converter 4, safety valve 5, heat exchanger 6, and lubricating oil circuit 7. An independent plug is used at the entrance of the clutch oil circuit. The way of installation is equipped with plug-in hydraulic buffer valves 8 and 9: the plug-in hydraulic buffer valves include pipe sleeves 8-10, there are shells 8-11 on the pipe sleeves, and valve cores 8-9 are arranged in the pipe sleeves. , there is also a valve stem 8-12 in the sleeve, springs 8-13, 8-14, 8-15 on the valve stem, a spring 8-4 and a spring seat 8-5 at the front end of the valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com