Fluidized bed reactor and method for synthesizing methyl chlorosilane by using same

A fluidized bed reactor and fluidized bed technology, applied in chemical instruments and methods, compounds of group 4/14 elements of the periodic table, organic chemistry, etc., can solve the problem of reducing the effective cross-sectional area of the bed and blowing out the catalyst from the bed , affect the reaction process and other issues, to achieve the effect of prolonging the synthesis production cycle, improving the macroscopic reaction speed, and increasing the particle concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

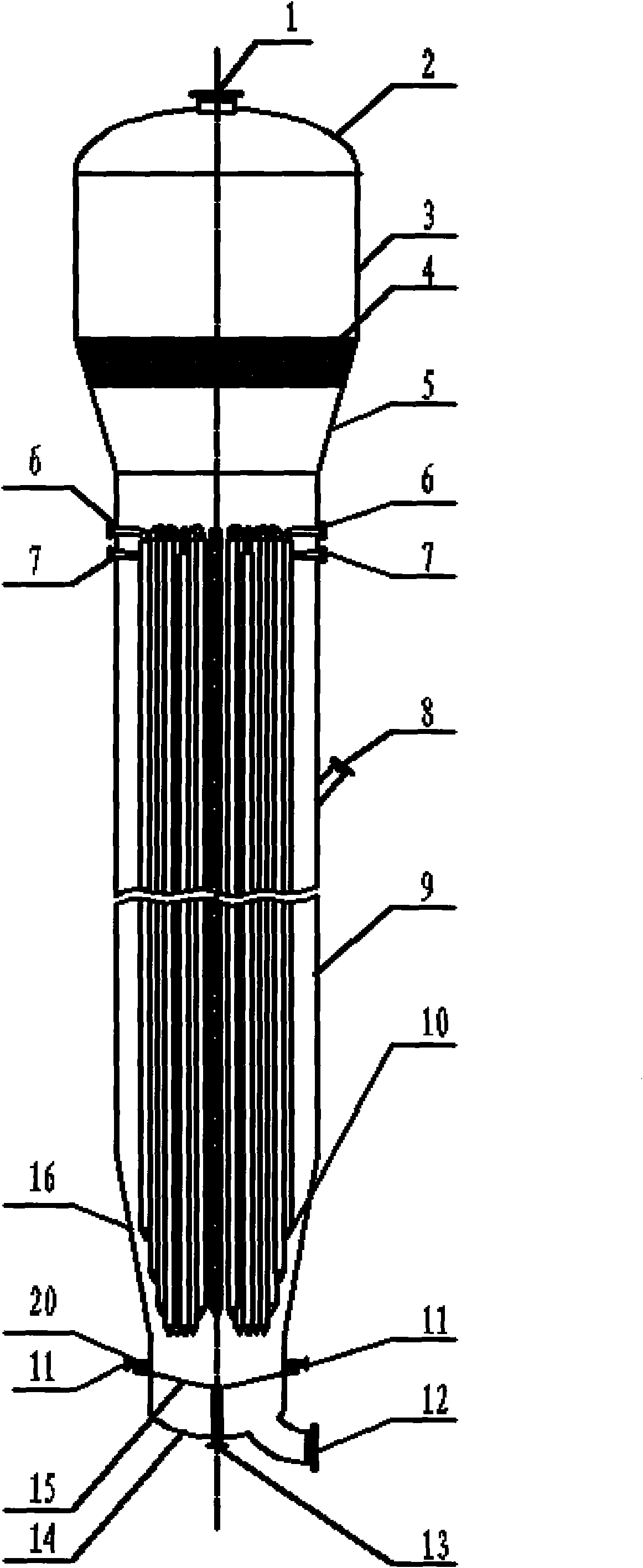

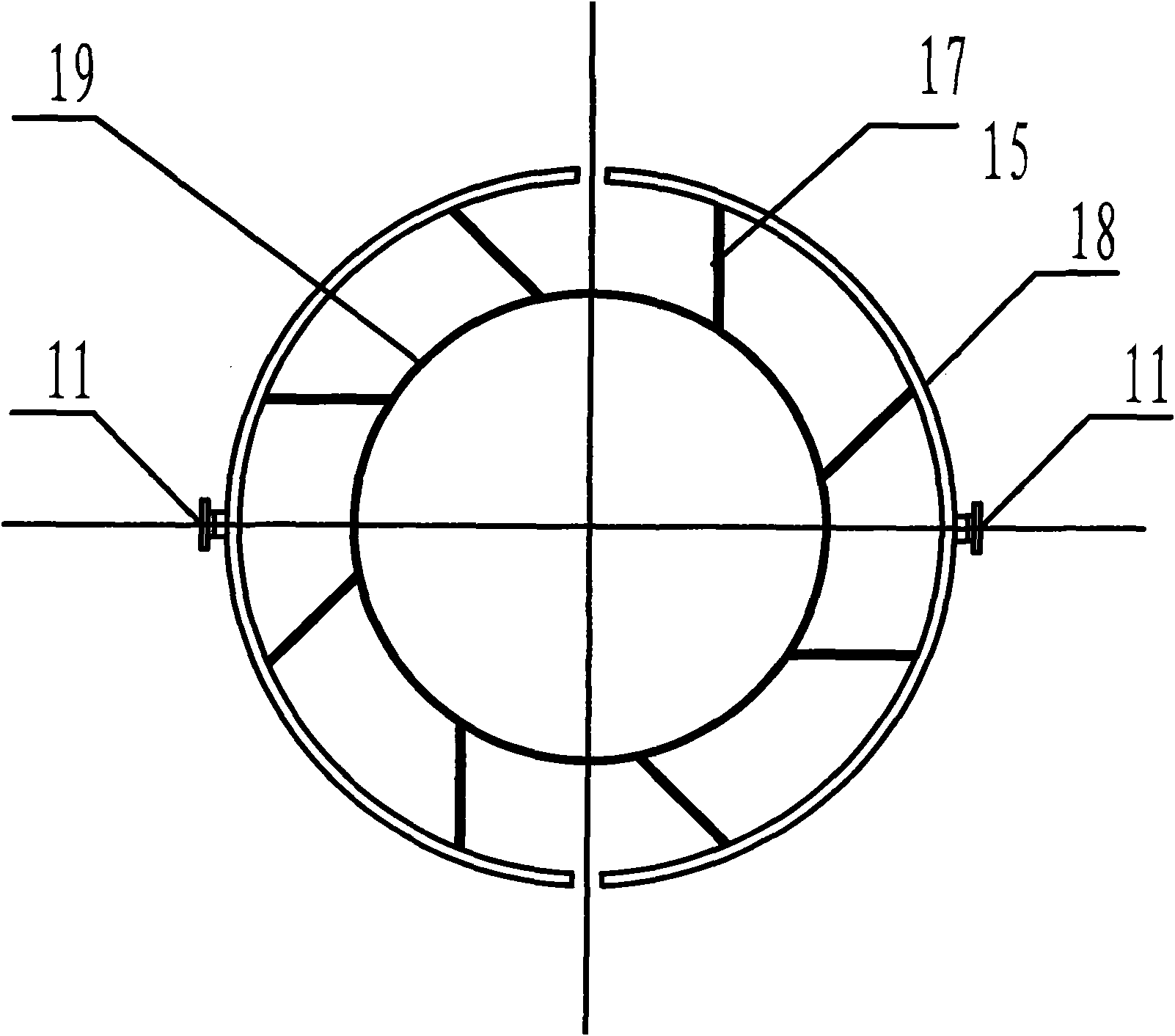

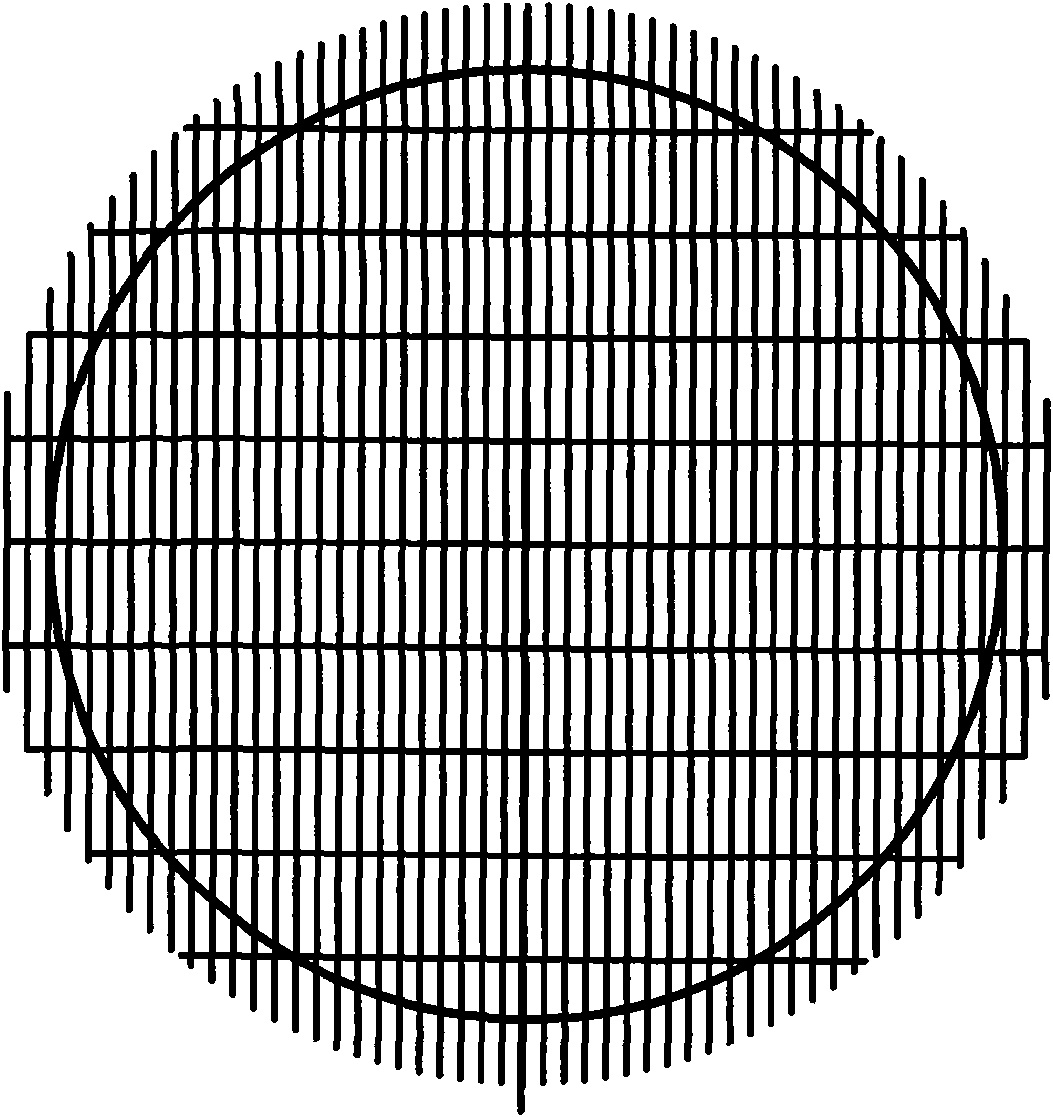

[0022] fluidized bed reactor

[0023] Such as figure 1 and figure 2 , the fluidized bed reactor includes a cylinder body 9, an enlarged section cylinder body 3, an upper cone body 5, a distribution plate 15 installed at the bottom of the fluidized bed, an inlet pipe 12 below the distribution plate, that is, a feed gas inlet, and inside the cylinder body The finger-shaped casing bundle 10, the feeding port 8, the slag discharge port 13 at the bottom, the upper head 2, and the lower head 14. The flow guide device is installed in the middle of the distribution plate 15 and the finger-shaped casing bundle 10. The lower end of the flow guide device is connected to the The top of the distribution plate 15 is connected, and its upper end is connected with the cylinder of the fluidized bed. The flow guide device includes a gas distribution pipe 18, a flow guide pipe 17 and a gas distribution flange 19. The gas distribution pipe 18 is composed of at least two bends. The lower end of...

Embodiment 2

[0025] Synthesis of Methylchlorosilane

[0026] As in the fluidized bed reactor of Example 1, there are 20 guide tubes, the angle between the guide tube 17 and the flange of the distribution plate is 30°, the length of the guide tube is 50 mm, and the pipe diameter DN is 20 mm. The diameter DN is 100mm. Adjust 35% of the total weight of the raw material gas methyl chloride to enter from the gas inlet 12 at the bottom of the fluidized bed, and the gas flow rate is 0.4m / s to form an axially flowing air flow, and the remaining 65% of the methyl chloride gas is fed into the gas inlet 11, The gas flow rate is 30m / s, so that the gas flow adds a tangential velocity on the basis of the original axial velocity. When the temperature is 280°C, the raw silicon powder particles, copper catalyst and co-catalyst are added from the fluidized bed raw material feeding port 8, As a result, the solid particles entrained in the raw material gas rise in a spiral shape, and the contact time between...

Embodiment 3

[0029] Synthesis of Methylchlorosilane

[0030] As in the fluidized bed of Example 1, a baffle layer 4 is installed in the fluidized bed, and the baffle layer is installed in the upper cone 5 of the cylinder body, and the height of the baffle layer is 30% of the height of the upper cone. The diversion device is installed in the middle of the distribution plate and the finger-shaped sleeve bundle. There are 36 diversion pipes. The angle between the diversion pipe and the flange of the distribution plate is 10°. The length of the diversion pipe is 50mm, and the diameter DN is 20mm. The pipe diameter DN is 150mm. Adjust 50% of the methyl chloride gas to enter from the gas inlet 12 at the bottom of the fluidized bed, and the gas flow rate is 0.35m / s to form an axially flowing air flow, and the remaining 50% of the methyl chloride gas is fed through the gas inlet 11, and the gas flow rate is 20m / s, so that the air flow adds a tangential velocity on the basis of the original axial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com