Explosive welding method of aluminum/titanium/steel three-layer composite material

A technology of explosive welding and composite materials, applied in welding equipment, welding/welding/cutting items, non-electric welding equipment, etc., can solve the problems of poor bonding strength of titanium/steel composite interface, difficult to control process parameters, etc., to avoid mechanical properties Inferior, Difficulty-Reducing Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

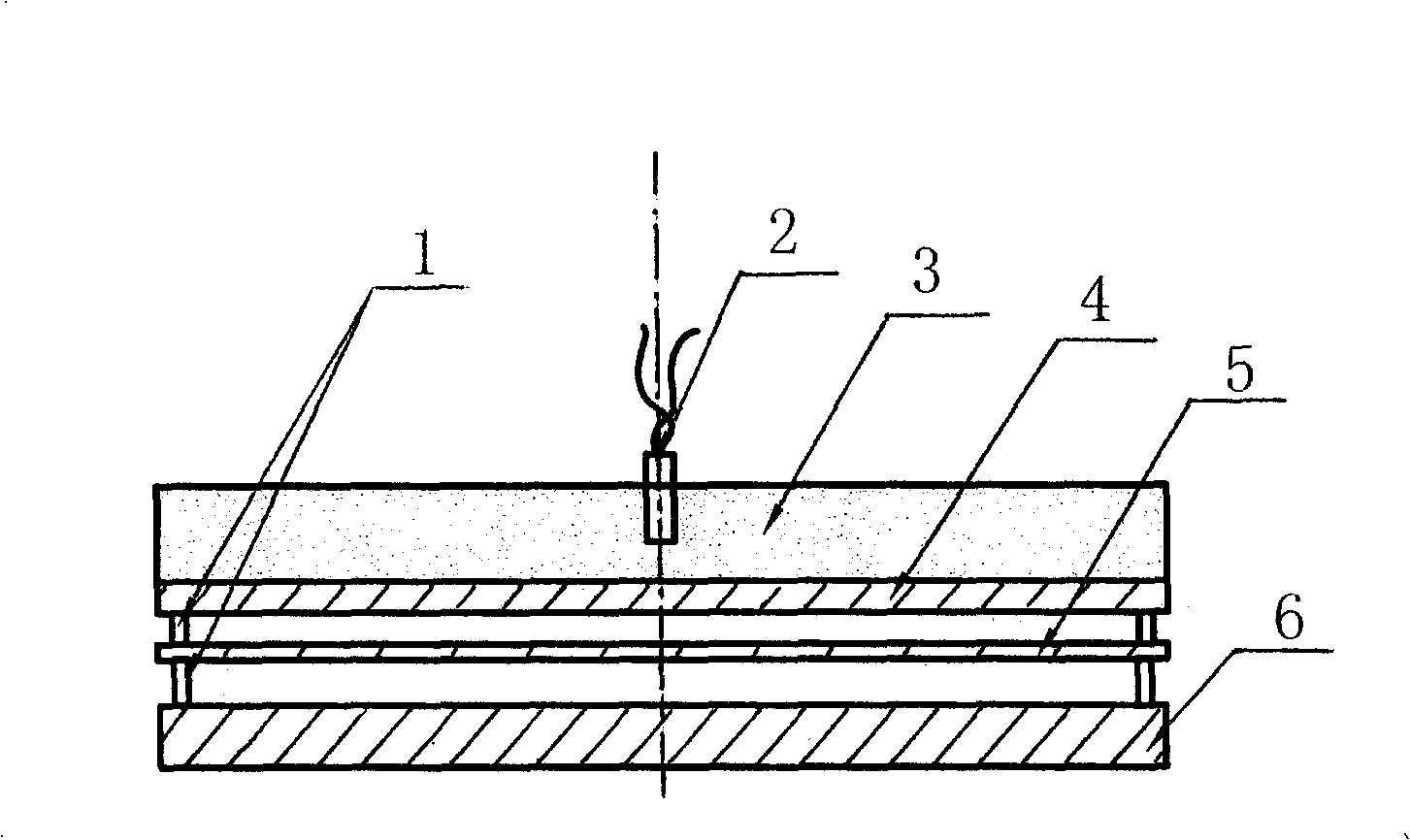

[0017] Such as figure 1 As shown, the two sides of the thin titanium plate 5, one side of the thin clad aluminum plate 4, and one side of the steel plate are polished with a polishing wheel to remove the surface oxide scale to reveal the metallic luster, and the steel plate 6 is placed on the sandy soil foundation, and the clad layers 4 and 5 are passed through The metal support is placed in parallel on top of 6, and the side treated by the grinding wheel on the surface of 4 faces down, and the explosive 3 is arranged on the untreated side of the surface of 4. The explosive is expanded ammonium oil explosive, and 8# industrial electric detonator is used 2 Detonation, explosive welding to obtain thin aluminum plate / thin titanium plate / steel explosive composite plate.

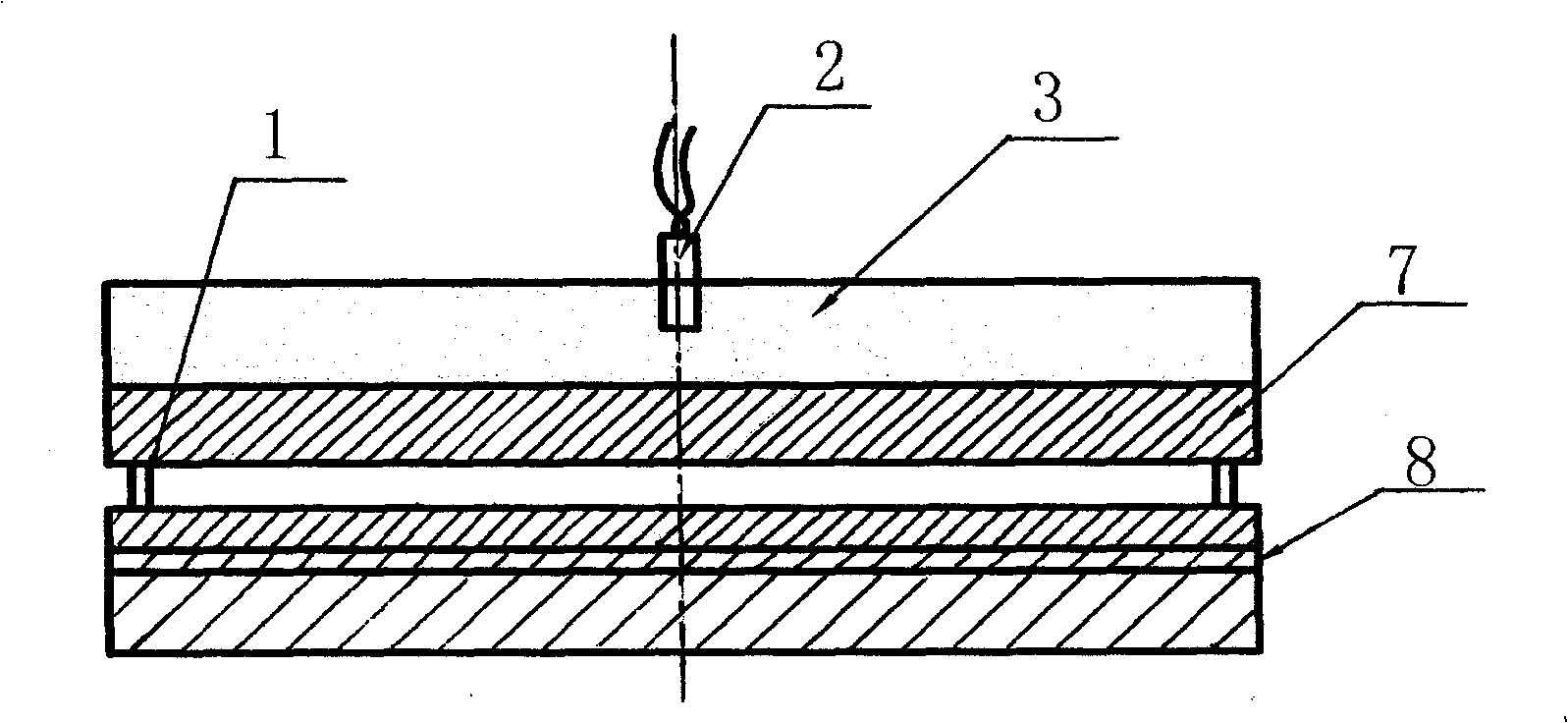

[0018] Such as figure 2 As shown, one side of the aluminum layer of the composite material 8 and one side of the thick aluminum plate 7 are polished with a polishing wheel to remove the surface scale, and the 7...

Embodiment 2

[0021] Such as figure 1 As shown, the two sides of the thin titanium plate 5, one side of the thin clad aluminum plate 4, and one side of the steel plate are polished with a polishing wheel to remove the surface oxide scale to reveal the metallic luster, and the steel plate 6 is placed on the sandy soil foundation, and the clad layers 4 and 5 are passed through The metal support is placed in parallel on top of 6, and the side treated by the grinding wheel on the surface of 4 faces down, and the explosive 3 is arranged on the untreated side of the surface of 4. The explosive is expanded ammonium oil explosive, and 8# industrial electric detonator is used 2 Detonation, explosive welding to obtain thin aluminum plate / thin titanium plate / steel explosive composite plate.

[0022] Such as figure 2 As shown, one side of the aluminum layer of the composite material 8 and one side of the thick aluminum plate 7 are polished with a polishing wheel to remove the surface scale, and the 7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com