CMABR (carbon tube membrane-aerated biofilm reactor) for running single-stage autotrophic biological nitrogen removal process

An autotrophic biological denitrification and membrane bioreactor technology, applied in the field of water treatment equipment, can solve problems such as pore blockage, and achieve the effects of large porosity, favorable adhesion and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention will be described in detail below in combination with technical solutions and accompanying drawings.

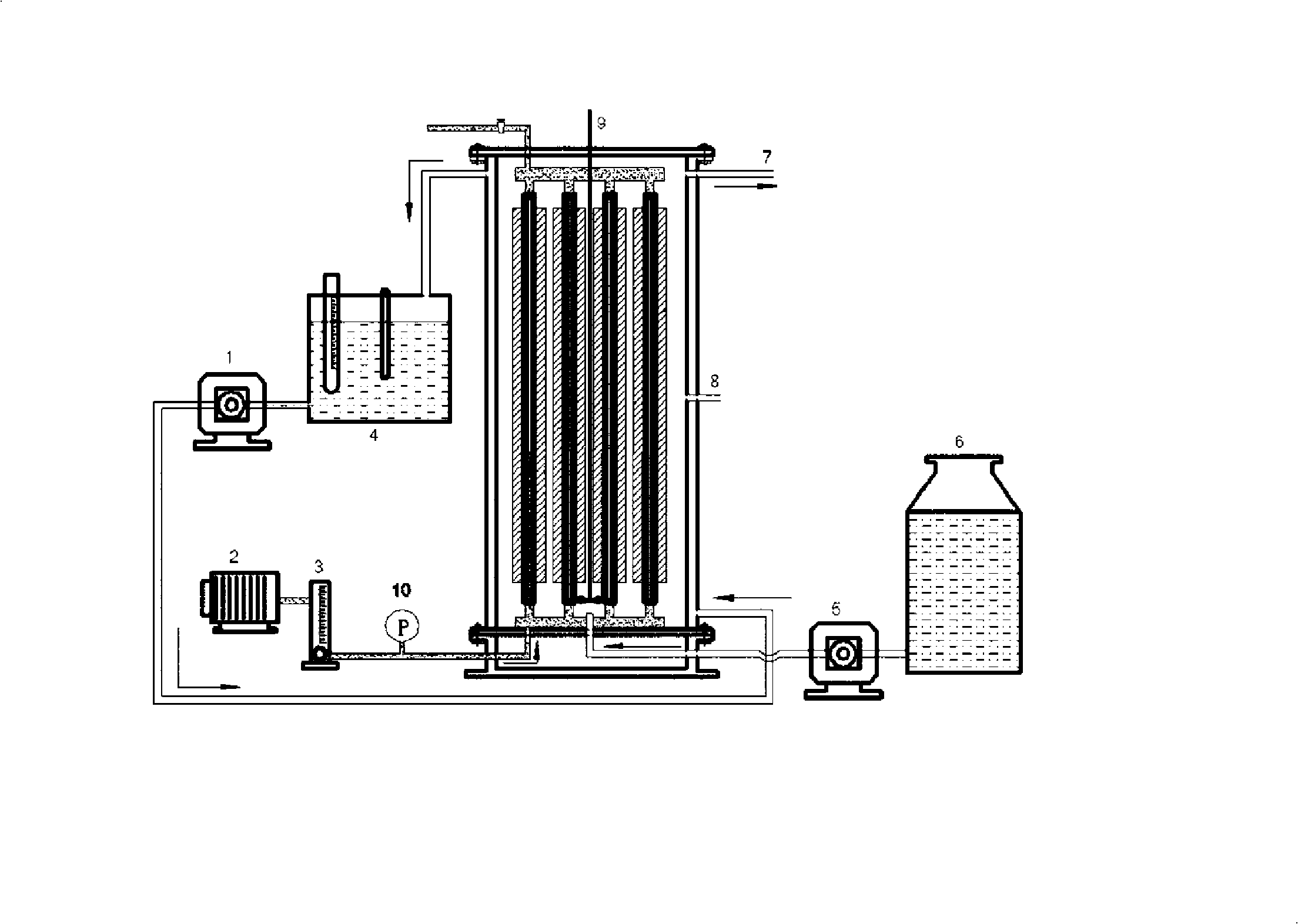

[0022] It can be seen from the flow diagram of the single-stage autotrophic biological denitrification process of MABR that the membrane module is composed of microporous carbon tube membranes 11 arranged vertically at equal distances, and each carbon tube is wrapped with non-woven fabric 12 to increase the reactor's biological protection. retention capacity. The temperature control device wherein consists of a heating water return pump 1 and a heating water tank 4, and its function is to create stable and suitable temperature conditions for microbial growth and metabolism. Dissolved oxygen is provided by the air pump 2, and the pressure in the inner chamber of the carbon tube membrane can be gradually controlled by adjusting the gas flow meter 3, so that the oxygen supply can be adjusted, and then the dissolved oxygen in the reacto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com