Groove flat-grid MOSFET component and fabricating method thereof

A manufacturing method and planar gate technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as threshold voltage difficulty, breakdown voltage drop, process cost increase, etc., to facilitate popularization and utilization, manufacturing method The effect of simplicity and low process cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

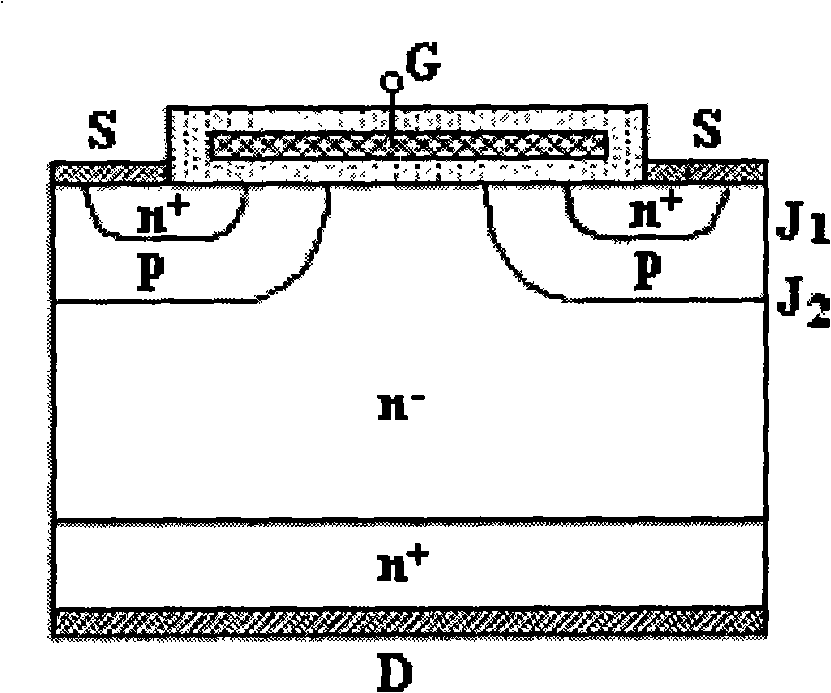

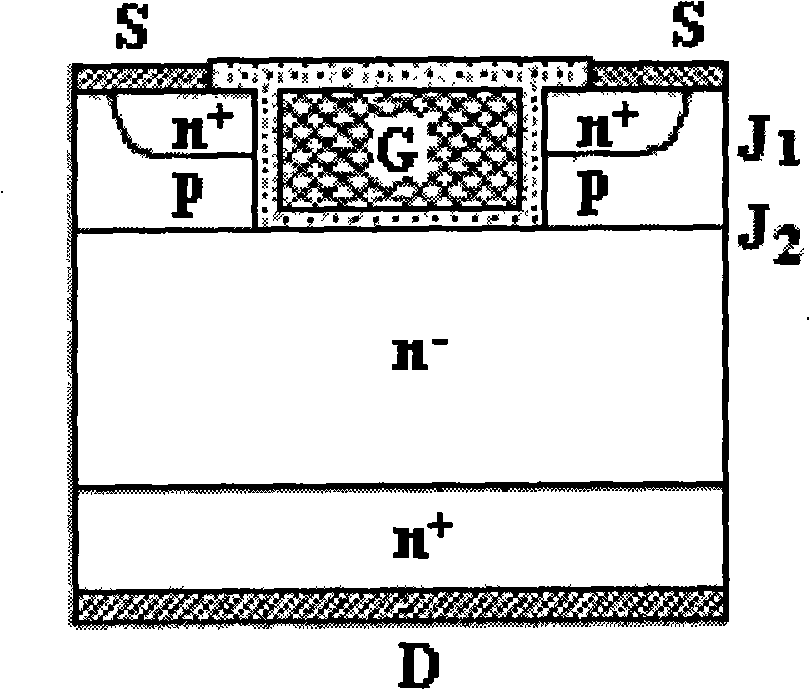

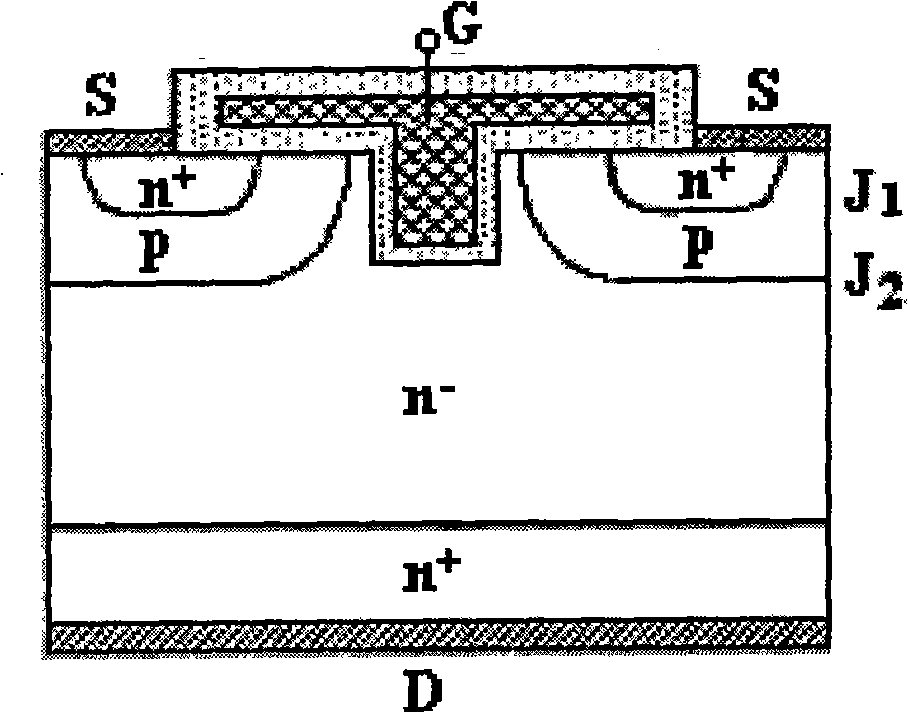

[0033] figure 1 and figure 2 They are schematic cross-sectional schematic diagrams of the basic structure of the existing planar gate VDMOS and trench gate VUMOS respectively. Depend on figure 1 It can be seen that the existing VDMOS structure is a planar gate, the channel is on the surface, and its length is composed of the p base region and the n + The difference between the lateral junction depths of the two diffusions in the source region is determined. Depend on figure 2 It can be seen that the trench gate of the existing trench gate VUMOS structure is connected to the source region, and the bottom of the trench enters the n - drift region, the channel is in the body, and its length is also determined by the p base region and n + The difference between the lateral junction depths of the two diffusions in the source region is dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com