Laser

A laser and laser gain technology, applied in the laser field, can solve the problems of high cost, complex structure, waste of pumping light energy, etc., and achieve the effect of improving absorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

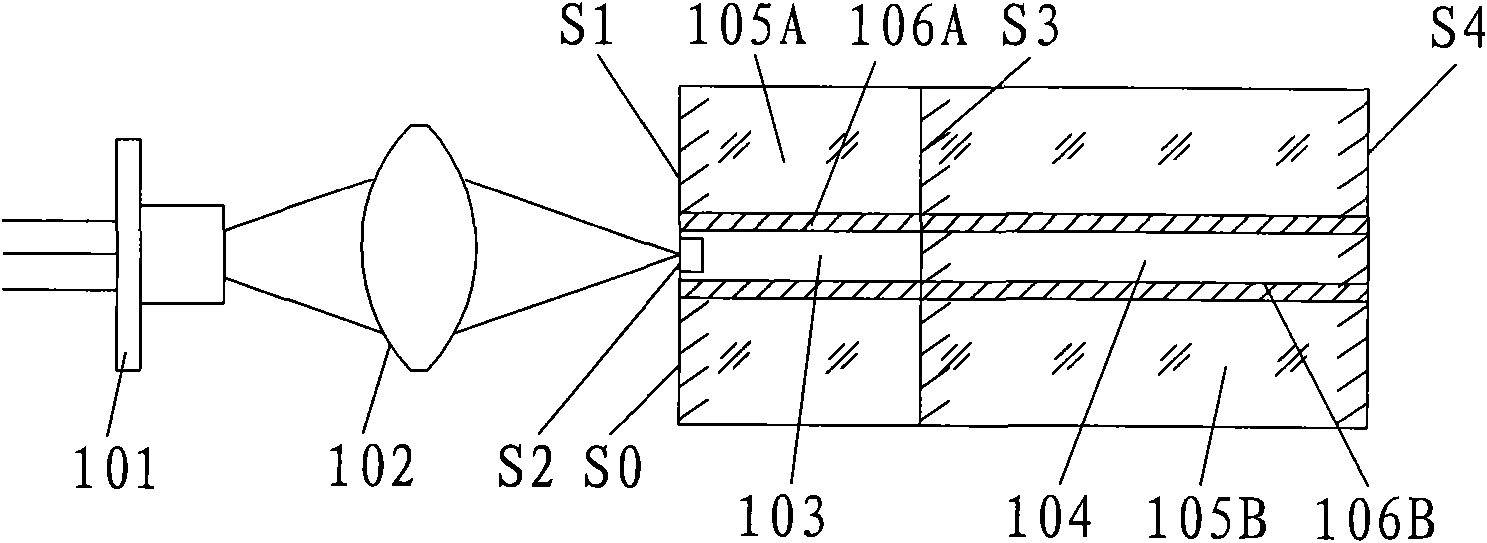

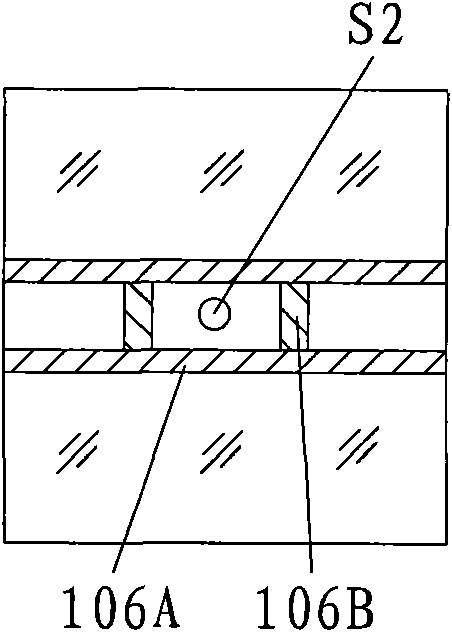

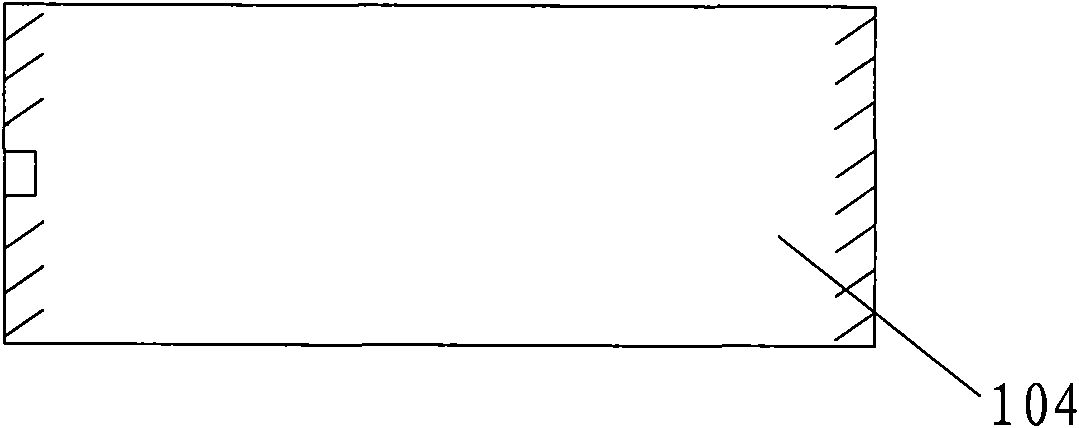

[0040] The invention adopts a new pumping cavity structure to improve the absorption efficiency of the laser gain medium to the pumping light. The structure includes LD pumping system, optical coupling system and resonant cavity. The gain medium in the resonant cavity can be rod-shaped, square-shaped, waveguide cavity, etc. On the pump light incident end face, except for the pump light through hole, the other surfaces that cannot produce total internal reflection are all coated with high-reflective pump light. The film layer is used to form a reflective cavity close to the closed structure of the pump light. After the LD pump light enters the gain medium, it will be reflected multiple times in the cavity of the pump light, most of which will be absorbed by the gain medium, and only a small amount will be lost through the aperture. Therefore, the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com