Dewatering power supply for rectangular-wave alternating-current crude oil

A crude oil dehydration and rectangular wave technology, applied in the direction of using electricity/magnetic dehydration/demulsification, adjusting electrical variables, and electrical program control, etc. Strong demulsification effect, overcoming the effect of trans-electric field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific structure of the present invention will be described below in conjunction with the accompanying drawings.

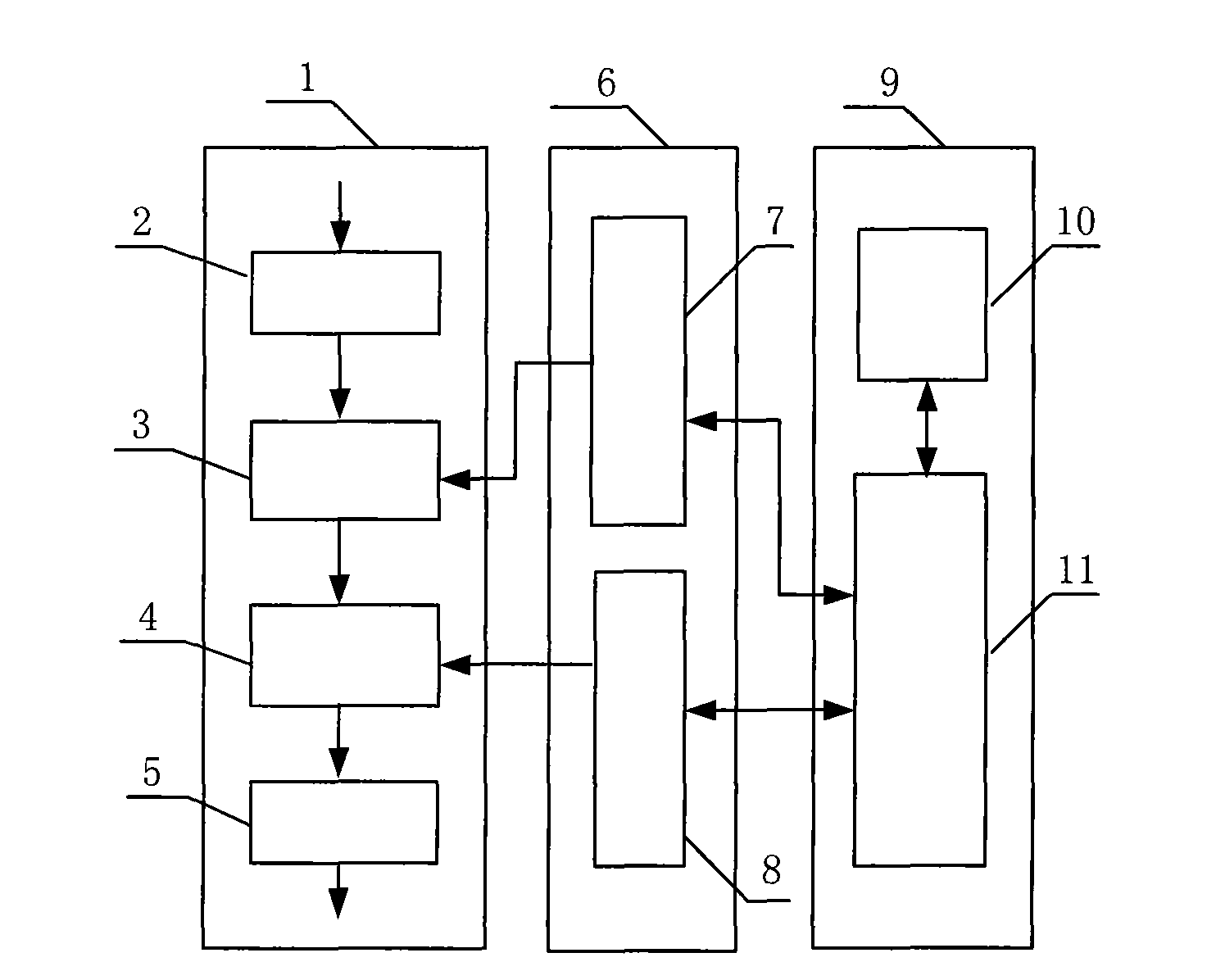

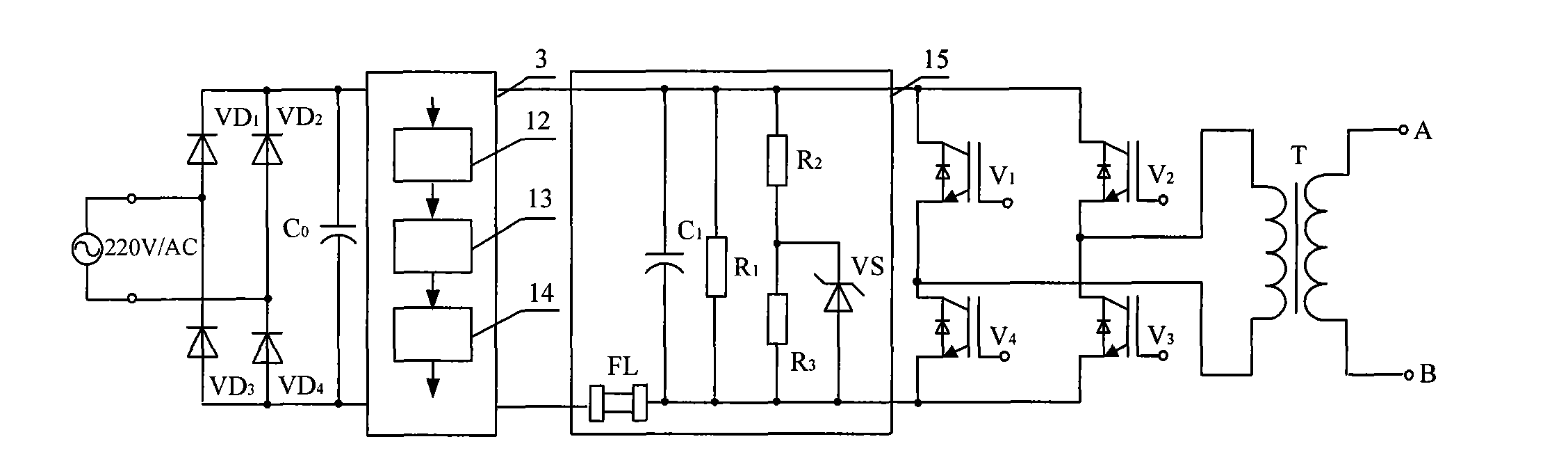

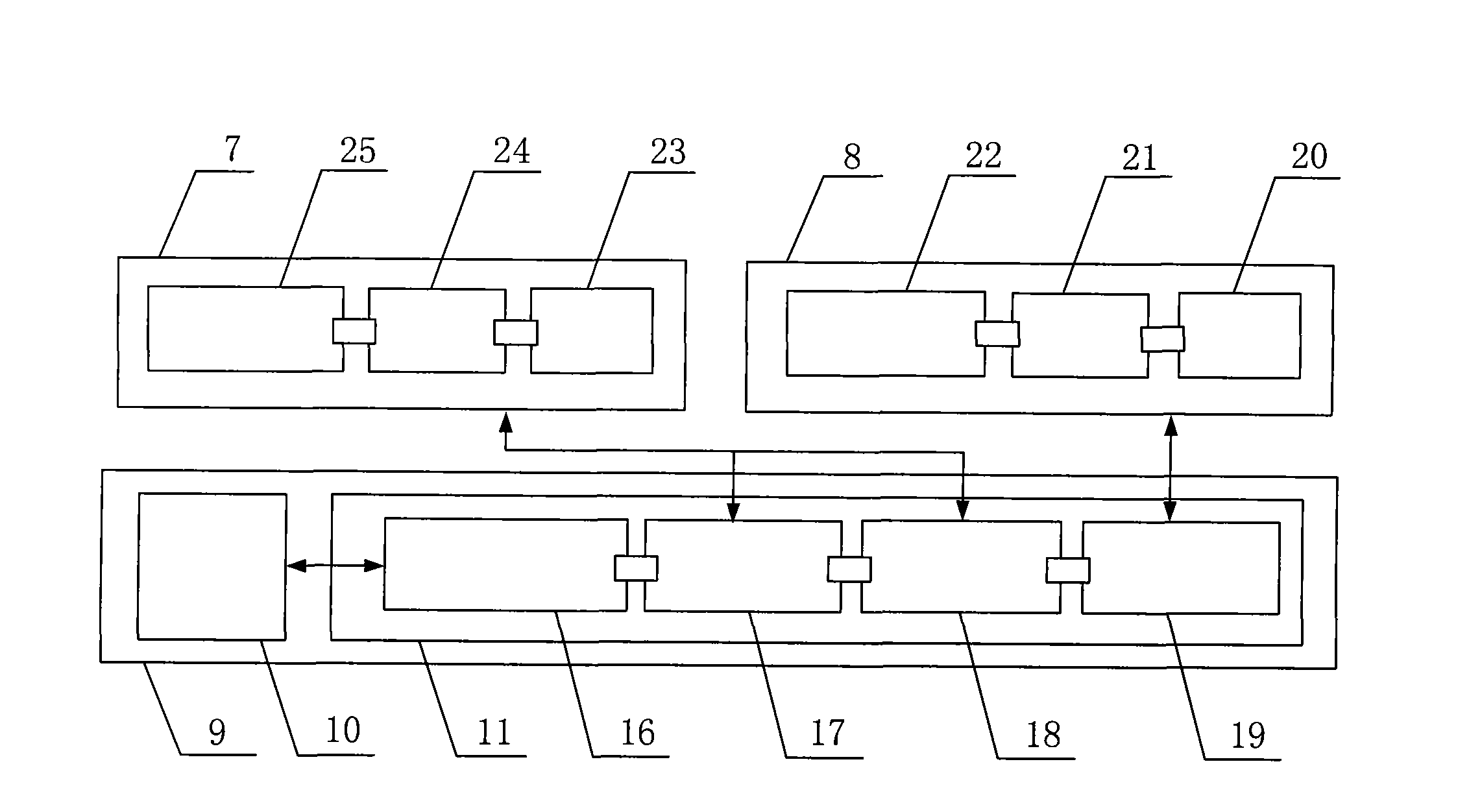

[0015] exist figure 1 Among them, the rectangular wave AC crude oil dehydration power supply of the present invention is composed of a main circuit 1, a control circuit 6 and an optimization control circuit 9 connected in series. The main circuit 1 is composed of a full-bridge uncontrollable rectification filter circuit 2, a voltage regulation circuit 3, a rectangular wave generating circuit 4 and an intermediate frequency transformer 5 in series. The control circuit 6 is composed of a voltage regulation control circuit 7 and a rectangular wave generation control circuit 8 . The optimization control circuit 9 is composed of an industrial control touch screen 10 and a PLC control circuit 11 connected in series. In the main circuit 1, when the power supply is working, 220V / 50Hz AC power is input to the full-bridge uncontrollable rectification filter c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com