Flame-resisting MAA/AN copolymer foam plastic and preparation method of flame-resisting agent used by the same

A foamed plastic and copolymer technology, applied in the field of MAA/AN copolymer foamed plastics, can solve problems such as poor flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

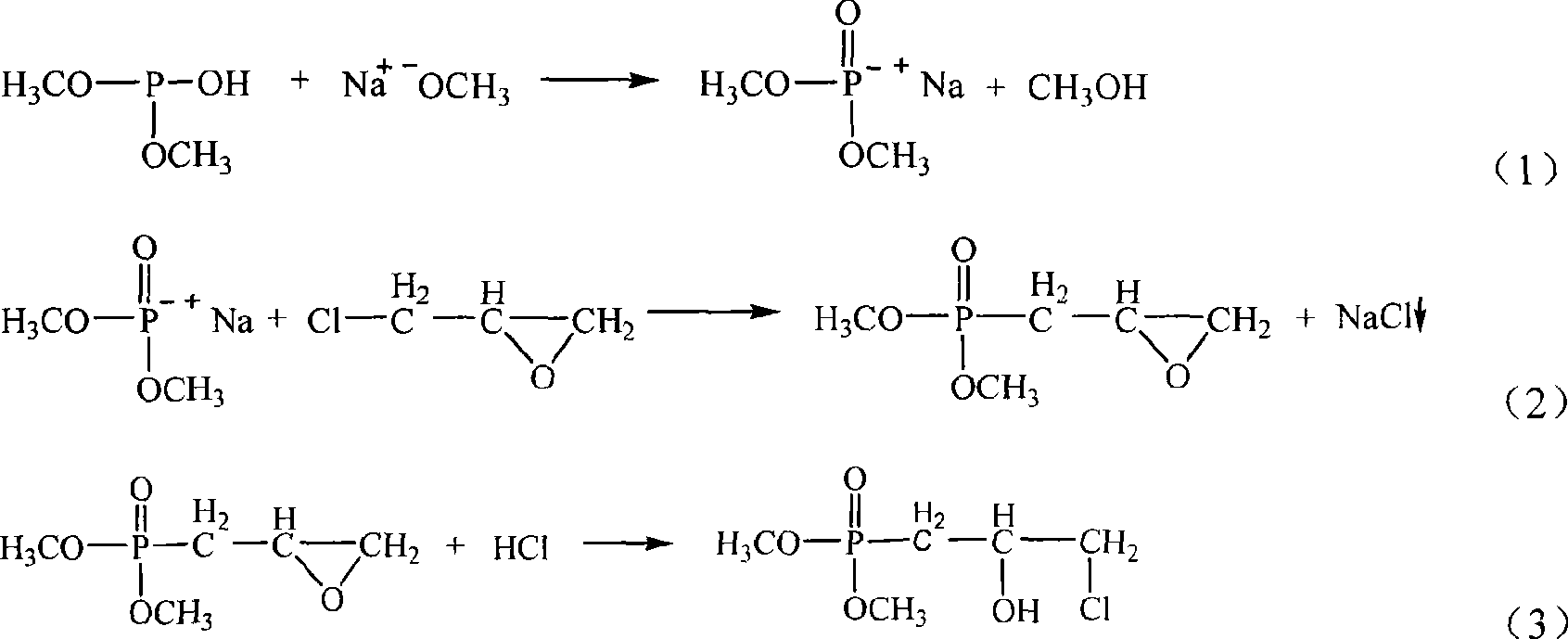

Method used

Image

Examples

preparation example Construction

[0044] The preparation method of above-mentioned flame-retardant MAA / AN copolymer foamed plastics comprises the steps:

[0045] Step 1, mixing the above formulations to form a uniform raw material solution;

[0046] Step 2, pour the raw material liquid into a mold made of two flat inorganic glasses and natural rubber or EPDM rubber or silicone rubber sealing ring, and the outside of the glass mold is tightened by a clamp;

[0047] Step 3: Put the glass mold filled with the raw material liquid into a strong circulating water bath device for polymerization to form a transparent foamable MAA / AN copolymer sheet. The polymerization conditions are: water temperature 40-60°C, time 24-72h.

[0048] Step 4. Freely foam the foamable MAA / AN copolymer sheet obtained in Step 3 in a strong circulating hot air at 180-200° C. (such as an oven, a drying tunnel, etc.) to form a foamed plastic.

[0049] Step 5: heat-treat the MAA / AN copolymer foam obtained in Step 4 in hot air (such as an oven)...

Embodiment 1

[0071] Embodiment 1 obtains density and is 60kg / m 3 The retarded flame MAA / AN copolymer foam plastics, embodiment 2 obtains density and is 60kg / m 3 Flame-retardant MAA / AN copolymer foamed plastics, embodiment 3 obtains density and is 80kg / m 3 The flame-retardant foamed plastics, embodiment 4 obtains density and is 110kg / m 3 flame retardant foam plastic. The density obtained in the control example is 60, 80kg / m 3 Non-flame retardant MAA / AN copolymer foam.

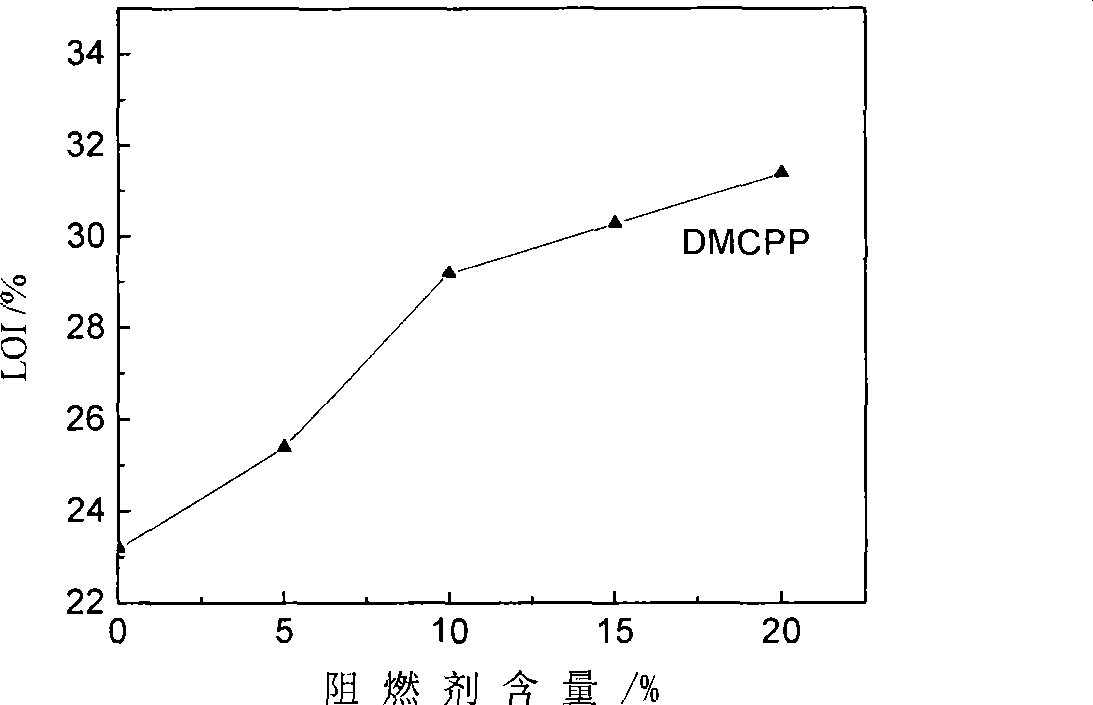

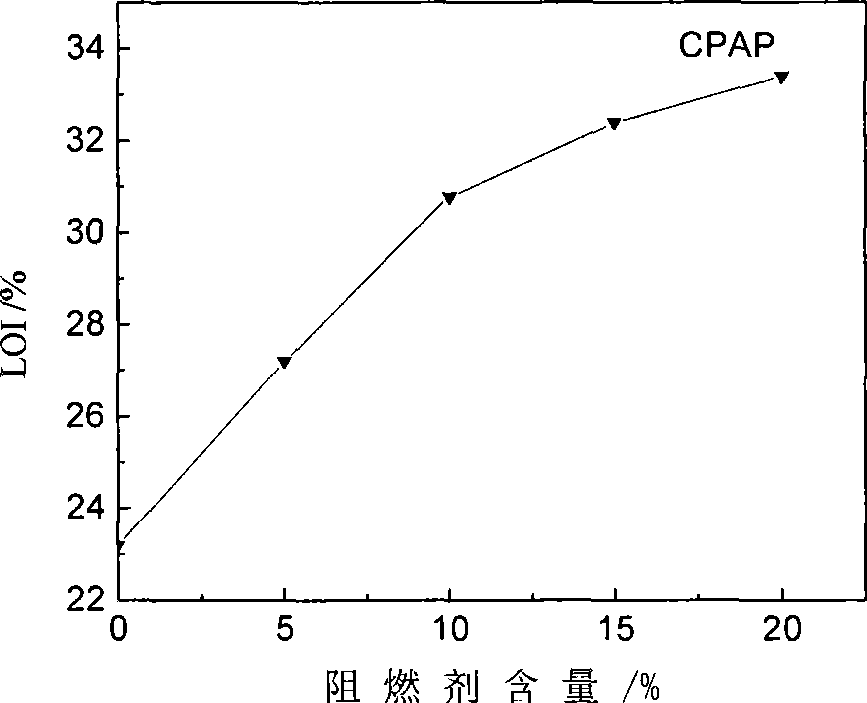

[0072] The combustion properties of the structural flame-retardant MAA / AN foamed plastics obtained in Examples 1-4 are shown in Table 2, compared with Document 1.

[0073] Table 2 Combustion properties of structural flame-retardant MAA / AN copolymer foams

[0074]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com