Polymeric composition, color filter and manufacturing method thereof, and liquid crystal display device

A technology of polymeric composition and polymeric compound, applied in optical filters, nonlinear optics, instruments, etc., can solve the problem of pixel residue and achieve the effect of suppressing discharge phenomenon in liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

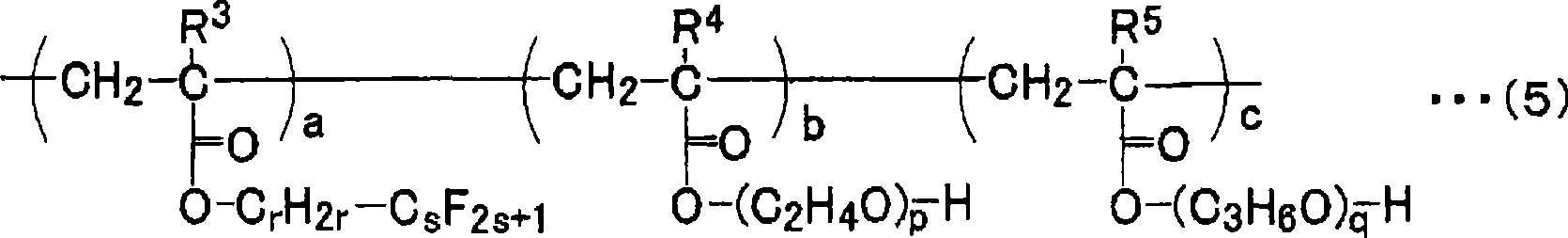

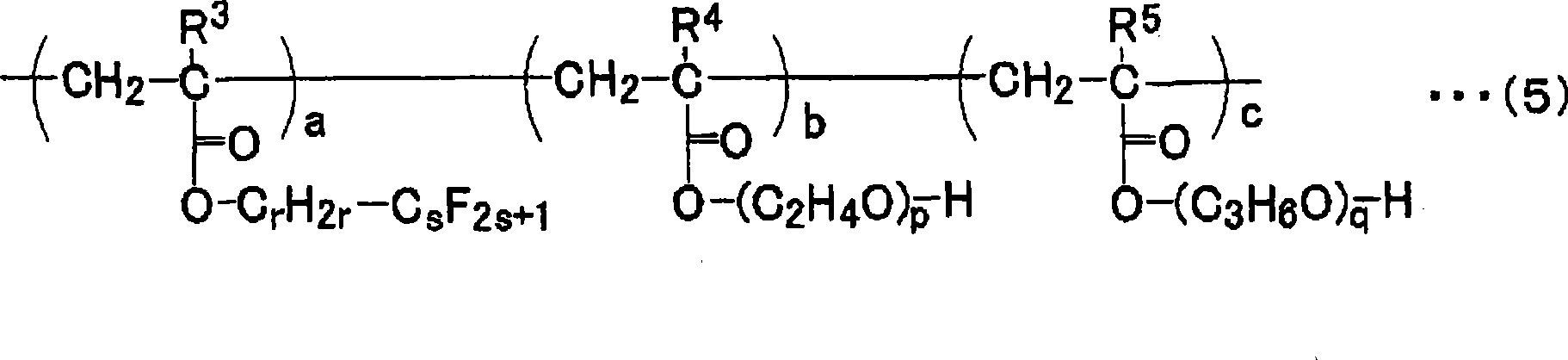

Method used

Image

Examples

Embodiment 1

[0161]

[0162] —Preparation of Carbon Black Dispersion (K—1)—

[0163] A carbon black dispersion (K-1) was prepared using the following recipe.

[0164] (Pigment Dispersion K—1)

[0165] ・Carbon black (Nipex 35 manufactured by Dizak Co., Ltd.) 13.1%

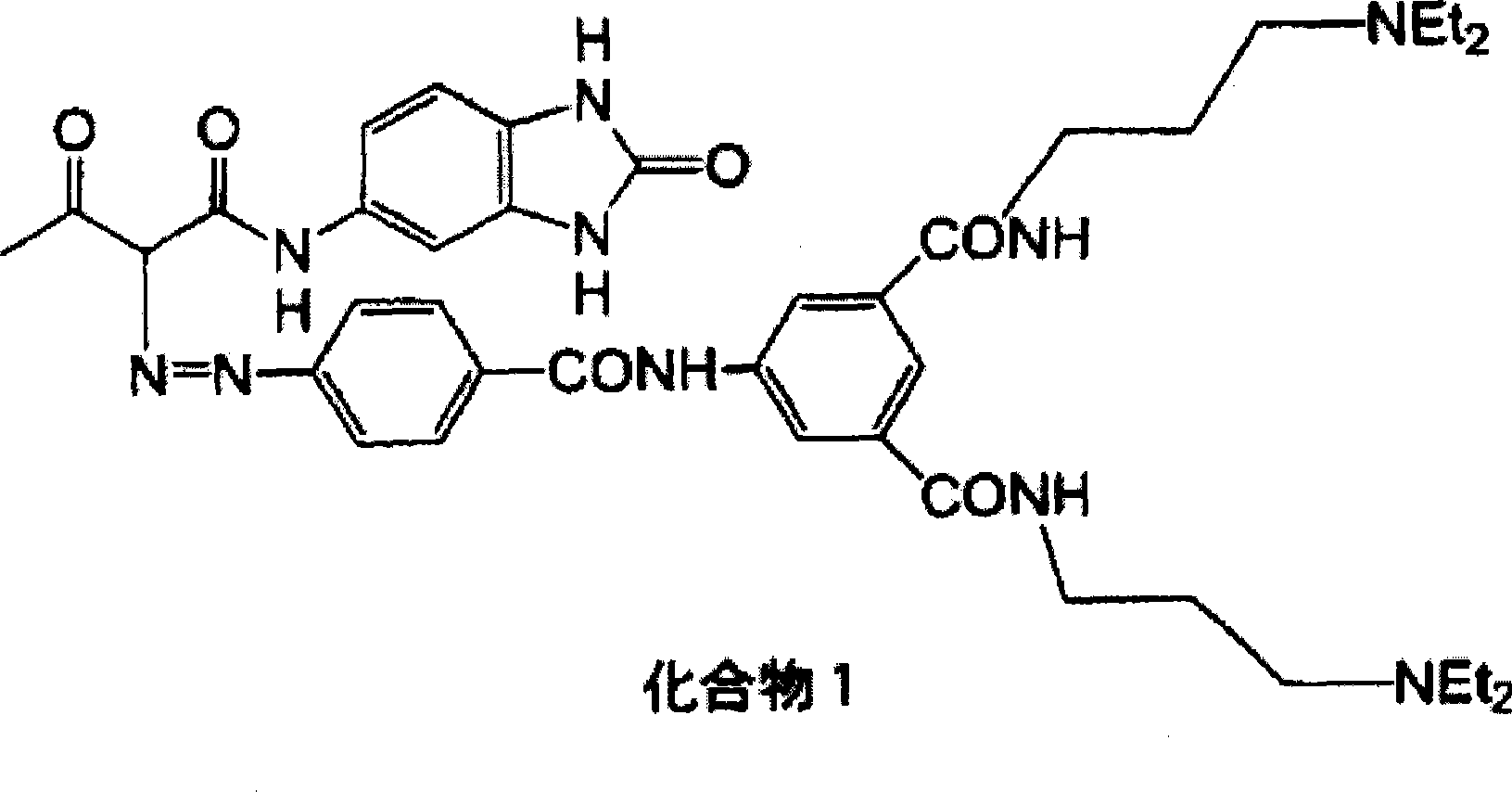

[0166] ・Dispersant (compound 1 below) 0.65%

[0167] ・Polymer (random copolymer of benzyl methacrylate / methacrylic acid=72 / 28 molar ratio, molecular weight 37,000)

[0168] 6.72%

[0169] · Methoxypropyl acetate (MMPGAc * Made by Daisy Road Company)

[0170] 79.53%

[0171] * Mixture with 1-methoxy-2-propyl acetate as the main component

[0172] 【Chemical 2】

[0173]

[0174] The above-mentioned components were mixed and stirred for 1 hour using a homogenizer under the condition of 3000 rpm. Using a bead disperser using 0.3 mm zirconia beads (trade name: dispersion pad, manufactured by GETZMANN), microdispersion treatment w...

Embodiment 2~ Embodiment 4、 comparative example 1~ comparative example 3

[0336] In Example 1, the polymerizable dark color composition coating liquid CK-1 was replaced by the polymerizable dark color composition coating liquid shown in Table 5, and the filter color was produced in the same manner as in Example 1. A liquid crystal display device was produced in the same manner as in Example 1 using the color filter, and an evaluation test of the color filter was performed in the same manner as in Example 1. The results are shown in Table 5.

Embodiment 5

[0338] In Example 4, the relative humidity when the polymerizable dark color composition coating liquid CK-4 was formed on the substrate was replaced with the relative humidity shown in Table 5, and the color filter was produced in the same manner as in Example 4. A liquid crystal display device was produced in the same manner as in Example 4 using the color filter, and an evaluation test of the color filter was performed in the same manner as in Example 1. The results are shown in Table 5. In addition, the evaporation rate of the (mixed) solvent when the evaporation rate of butyl acetate is set to 1 is described in the column of "evaporation rate of solvent in polymerizable composition" in Table 5 (the same applies to Tables 6 to 8).

[0339] 【table 5】

[0340]

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com