Method for preparing biocompatible high-strength three-dimensional connected porous PVA hydrogel

A biocompatible, high-strength technology, applied in the field of biomedical materials, can solve the problems of inability to obtain a porous structure, time-consuming pore-forming agents, and many closed-pore structures, and achieves a solution that avoids early dissolution, is easy to operate, and has a uniform pore size. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

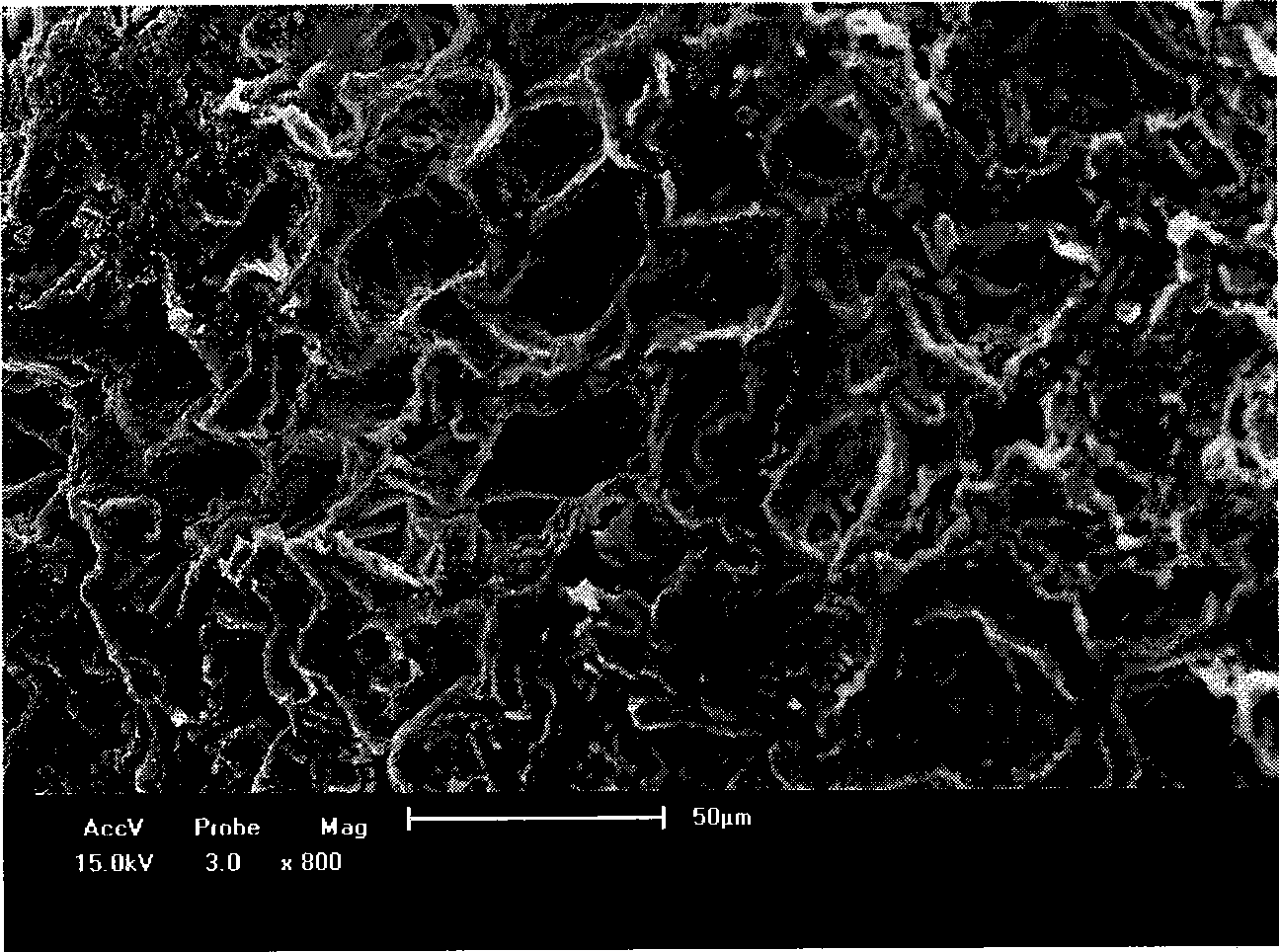

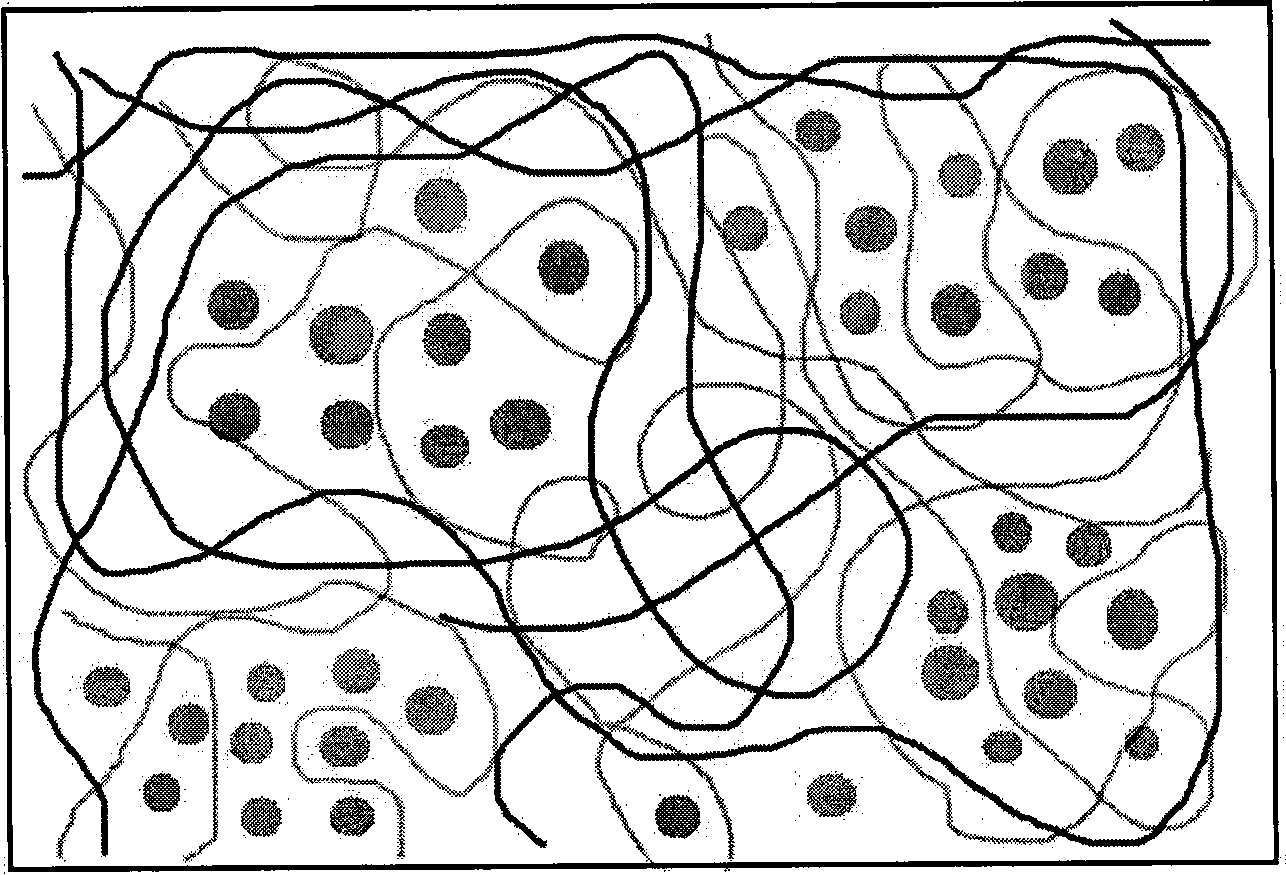

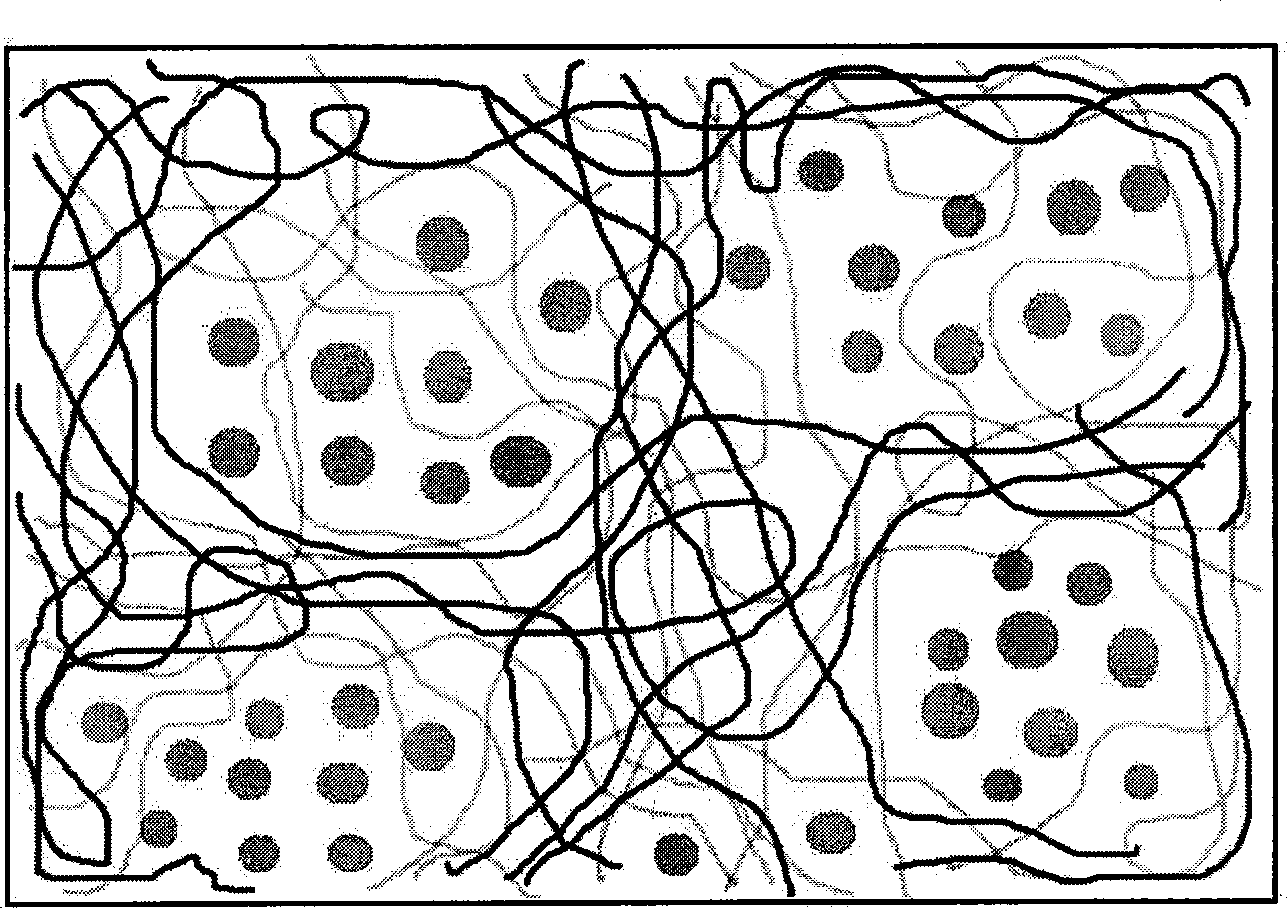

[0024] Weigh different masses of PVA solid particles and mix them with deionized water to prepare PVA aqueous solutions with three different concentrations of 10%, 15% and 20%, and put them into a high-pressure steam container to heat and dissolve, and the pressure in the container is maintained at 110MPa , the temperature was 110°C, and after heating for 1.5 hours, the homogeneously dissolved PVA solution was taken out, and allowed to stand to cool to room temperature. Add the same mass of OP-sodium chloride particles mixed porogen 10g (mass ratio 1:1) dropwise to the three solutions respectively, and stir at a speed of 100r / min at the same time. Pour the mixed PVA solution into a stainless steel mold, freeze at -20°C for 10 hours, and then thaw at room temperature for 3 hours, and freeze and thaw 6 times in this cycle. After the sample was formed, it was placed in a water bath at 25°C and cleaned with an ultrasonic cleaner for 0.5 hours to obtain the final sample. The test ...

example 2

[0026] Weigh a certain amount of PVA solid particles, mix it with deionized water to prepare a PVA aqueous solution with a concentration of 15%, put it into a high-pressure steam container and heat it to dissolve. The pressure in the container is maintained at 120MPa and the temperature is 120°C. The homogeneously dissolved PVA solution was taken out, allowed to stand and cooled to room temperature, and 50 g of the solution was equally weighed and placed in three beakers. Weigh 5g, 10g, 50g of OP-sodium chloride particle mixed porogen (mass ratio 1:1) into three beakers and mix with PVA solution. Stir evenly at a speed of 100r / min, pour the solution into a stainless steel mold, freeze at -20°C for 10 hours, then thaw at room temperature for 3 hours, and freeze and thaw 6 times in this cycle. After the sample was formed, it was placed in a water bath at 25°C and cleaned with an ultrasonic cleaner for 1 hour to obtain the final sample. The test results show that with the increa...

example 3

[0028]Different amounts of OP and NaCl solid particles were weighed and mixed to prepare three OP-sodium chloride particle mixed porogens with mass ratios of 2:1, 1:1, and 1:2. Weigh a certain amount of PVA solid particles, mix it with deionized water to prepare a PVA aqueous solution with a concentration of 15%, put it into a high-pressure steam container and heat it to dissolve. The pressure in the container is maintained at 120MPa and the temperature is 120°C. Take out the homogeneously dissolved PVA solution and let it cool down to room temperature. 50 g of the solution was weighed in equal amounts and placed in three beakers, and 5 g of three mixed porogens with different proportions were added respectively, while stirring at a speed of 90 r / min. Pour the uniformly mixed solution into a stainless steel mold, freeze at -20°C for 10 hours, then thaw at room temperature for 3 hours, and freeze and thaw 6 times in this cycle. After the sample was formed, it was placed in a w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com