Alginate co-extruded enteric coating glue, preparation method therefor and obtained co-extruded enteric coating

A technology of alginate and casing glue, applied in sausage casings, slaughtering, food science, etc., can solve the problems of unstable strength of co-extruded casings, affecting the appearance and taste of sausages, and high water vapor transmission rate. The effect of low pass rate, low price and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

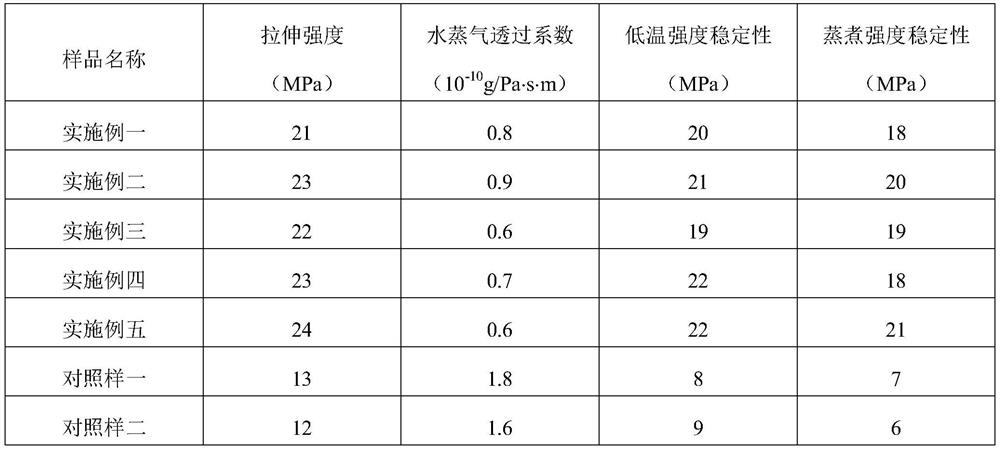

Examples

preparation example Construction

[0028] The preparation method of the alginate co-extruded enteric casing gum of the present invention comprises the following steps: taking the alginate composite glue and calcium suspension, mixing and stirring evenly to obtain the alginate co-extruded enteric casing gum.

[0029] A kind of alginate co-extruded casing of the present invention comprises casing glue and forming liquid; The casing glue is the alginate co-extruding casing glue described in any one of the above; The forming liquid includes soluble calcium salt 9-18 %, 1-2% of weak acid and 80-90% of water, the forming liquid is sprayed onto the surface of the casing glue during coaxial extrusion with the meat stuffing in the co-extrusion casing equipment, the forming The spray speed of the liquid is 100-200mL / min.

[0030] Preferably, the weak acid is any one or more of citric acid and lactic acid; preferably, the soluble calcium salt is calcium chloride.

Embodiment 1

[0032] A kind of preparation method of alginate co-extruded casing of the present invention comprises the following steps:

[0033] 1) Preparation of alginate composite glue

[0034] Take sodium alginate, natural starch, soybean protein, Tween 40 and sodium phosphate, mix and stir evenly to make alginate composite powder; the mass concentration of sodium alginate in the alginate composite powder is 65%, alginate The mass concentration of natural starch in the composite powder is 7%, the mass concentration of Tween 40 is 3%, the mass concentration of soybean protein is 20%, and the mass concentration of sodium phosphate is 10%.

[0035] Add water to the above-mentioned alginate composite powder, and stir evenly to prepare an alginate composite glue with a mass concentration of 5%.

[0036] 2) Preparation of calcium suspension

[0037] Take calcium sulfate, sodium phosphate and vegetable oil, mix and stir evenly to obtain a calcium suspension; the mass concentration of calcium...

Embodiment 2

[0043] A kind of preparation method of alginate co-extruded casing of the present invention comprises the following steps:

[0044] 1) Preparation of alginate composite glue

[0045] Take sodium alginate, pectin, propylene glycol alginate, pea protein and sodium pyrophosphate, mix and stir evenly to make alginate composite powder; the mass concentration of sodium alginate in the alginate composite powder is 65%, fruit The mass concentration of gum is 10%, the mass concentration of propylene glycol alginate is 3%, the mass concentration of pea protein is 15%, and the mass concentration of sodium pyrophosphate is 7%.

[0046] Add water to the above-mentioned alginate composite powder, and stir evenly to prepare an alginate composite glue with a mass concentration of 10%.

[0047] 2) Preparation of calcium suspension

[0048] Get calcium citrate, disodium edetate and vegetable oil, mix, stir evenly, get calcium suspension; The mass concentration of calcium citrate in the calciu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com