Production formula and production process of non-woven fabrics for medical healthcare

A technology for medical and health care and production technology, applied in the fields of medical science, non-woven fabrics, melt spinning, etc., can solve the problems of high cost, increased production cost, poor comfort, etc., and achieve the effect of high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) 75-80% (percentage by weight) of low-melting polypropylene as the main raw material, 18-23% (percentage by weight) of low-melting ethylene polymer and 2% (percentage by weight) of fatty amides are mixed together, and Add a small amount of color masterbatch.

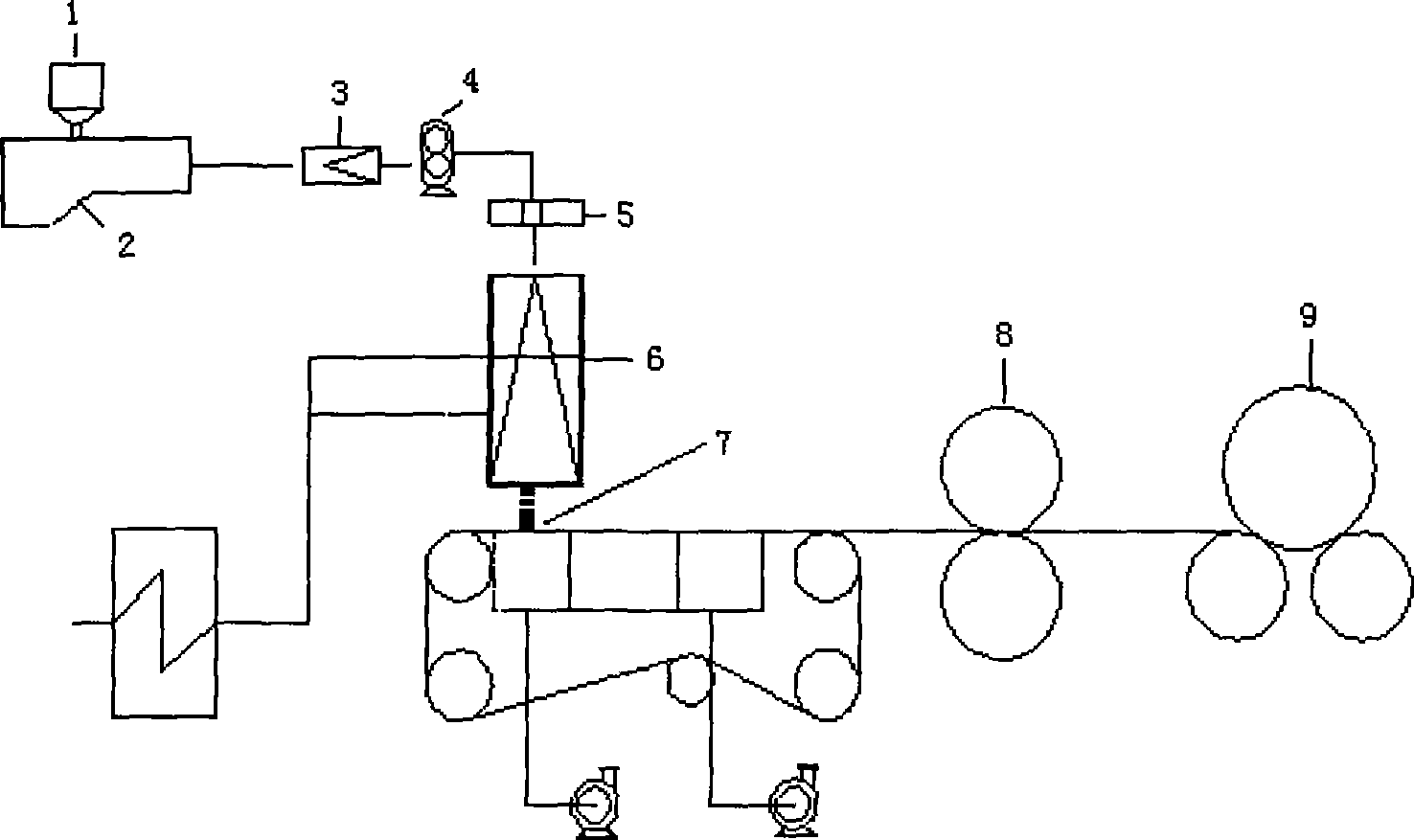

[0037] (2) According to the spunbond production process, the prepared raw materials are made after feeding 1, melting 2, filtering 3, metering 4, spinning 5, drawing and cooling 6, web forming 7, hot rolling 8, and winding 9.

Embodiment 2

[0039] (1) Mix the low-melt-point polypropylene with a melt index of 36g / 10min and the low-melt-point ethylene copolymer with a melt index of 18g / 10min according to the weight percentage ratio of 4:1, and then add 2% (weight percentage) of fat The color masterbatch of amide compound and 0.2% (percentage by weight) is allocated;

[0040] (2) According to the spunbond production process, the prepared raw materials are made after feeding 1, melting 2, filtering 3, metering 4, spinning 5, drawing and cooling 6, web forming 7, hot rolling 8, and winding 9.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt finger | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com