A kind of antibacterial treatment method of silk fiber or its fabric

A processing method and technology for mulberry silk fibers, applied in the field of natural silk fabrics, can solve the problems of human health hazards, poor antibacterial broad-spectrum, unreliable safety, etc., and achieve the effects of simple process and obvious antibacterial effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

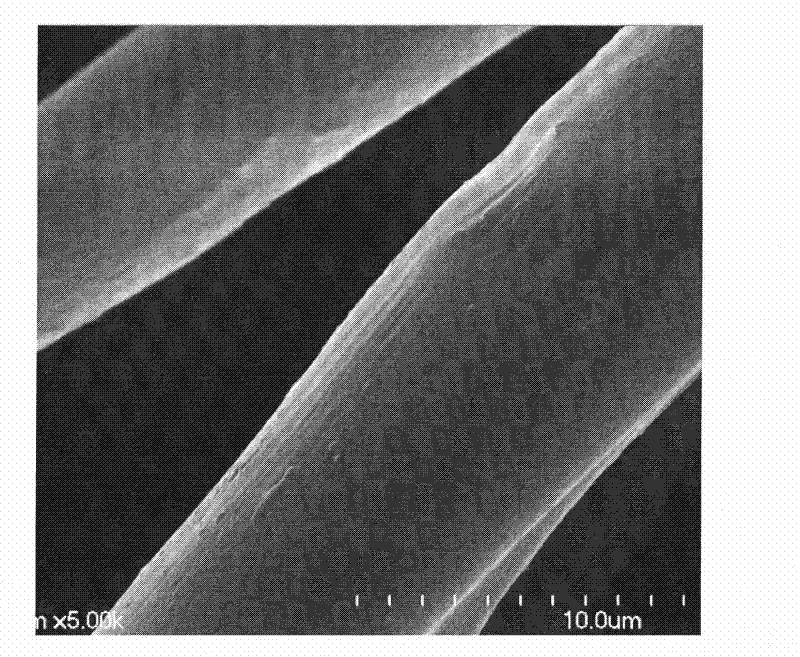

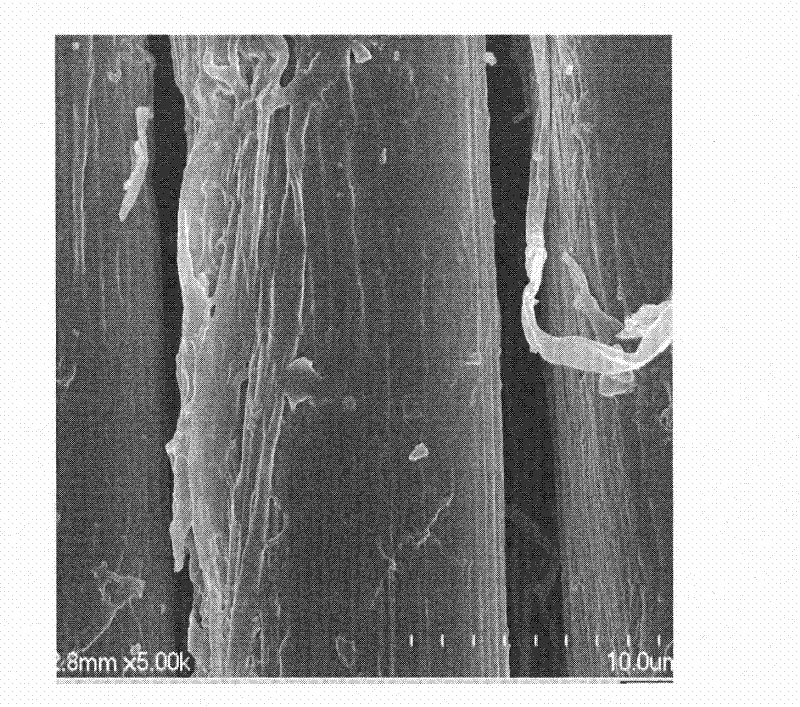

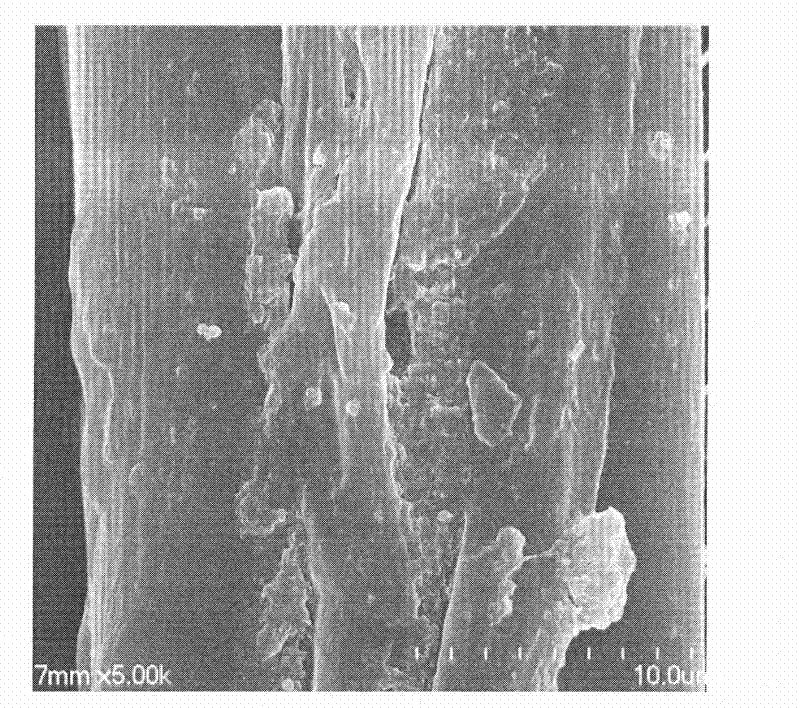

Image

Examples

Embodiment 1

[0044] Take 10g of mulberry silk fiber, adjust the water content of mulberry silk fiber to 50%, then immediately place the sample in a liquid nitrogen tank with a temperature of -196°C for 72 hours, then take out the sample and immediately put it in a vacuum drying oven , reheat for 3 hours at an absolute vacuum of 10kPa and a temperature of 100°C, then open the vacuum box, wait for the temperature to return to room temperature, take out the sample, and save it for later use. The samples were left for 15 days for antibacterial testing.

Embodiment 2

[0046] Get 10g of mulberry silk fiber, adjust the water content of mulberry silk fiber to 80%, and the freezing temperature is -80°C, and the freezing time is 24h. After that, the sample is taken out, and immediately put into a vacuum drying box. ×10 -2 Pa, rewarm at 100°C for 3 hours, then open the vacuum box, take out the sample when the temperature returns to room temperature, and save it for later use. The samples were left for 35 days for antibacterial testing.

Embodiment 3

[0048] The antibacterial test adopts the antibacterial fabric test method in the textile industry standard of the People's Republic of China-antibacterial knitwear (FZ / T 73023-2006): shaking flask method.

[0049] The antibacterial effect test is carried out to the silk fiber after the low-temperature freezing treatment of embodiment 1 and Example 2, and the antibacterial performance of the silk fiber without ultra-low temperature freezing treatment is tested simultaneously, and the results are shown in Table 1:

[0050] Table 1. Antibacterial properties of mulberry silk fiber before and after treatment

[0051] project

[0052] The results showed that the silk had a certain antibacterial effect before ultra-low temperature freezing treatment, but it was not significant; the antibacterial effect of the samples after antibacterial treatment on Escherichia coli, Bacillus subtilis, Staphylococcus aureus and other test bacteria was significantly enhanced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com