Anti-faking paper boards of corrugated coating and production thereof

A technology of corrugated cardboard and corrugated paper, which is applied to anti-counterfeit corrugated cardboard and its manufacture. The application field of anti-counterfeit corrugated cardboard in the preparation of anti-counterfeit corrugated boxes can solve the problems of easy evasion of anti-counterfeiting technology, weak anti-imitation ability, and difficult management and control. Improve physical and technical performance indicators, anti-counterfeit reliability, and low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Example 1 5-layer anti-counterfeiting corrugated cardboard and its preparation

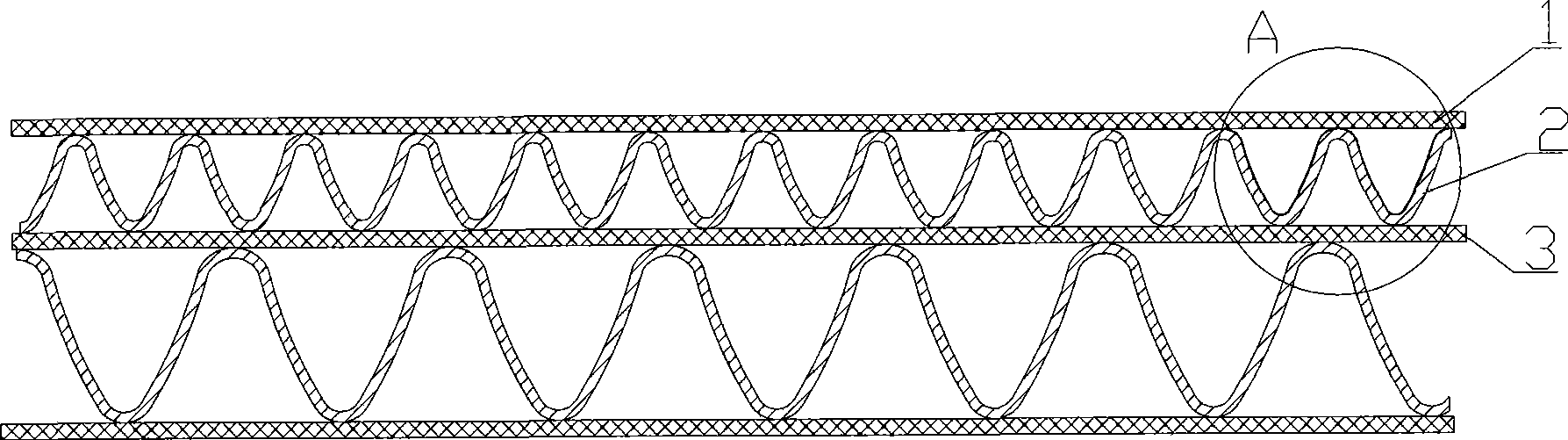

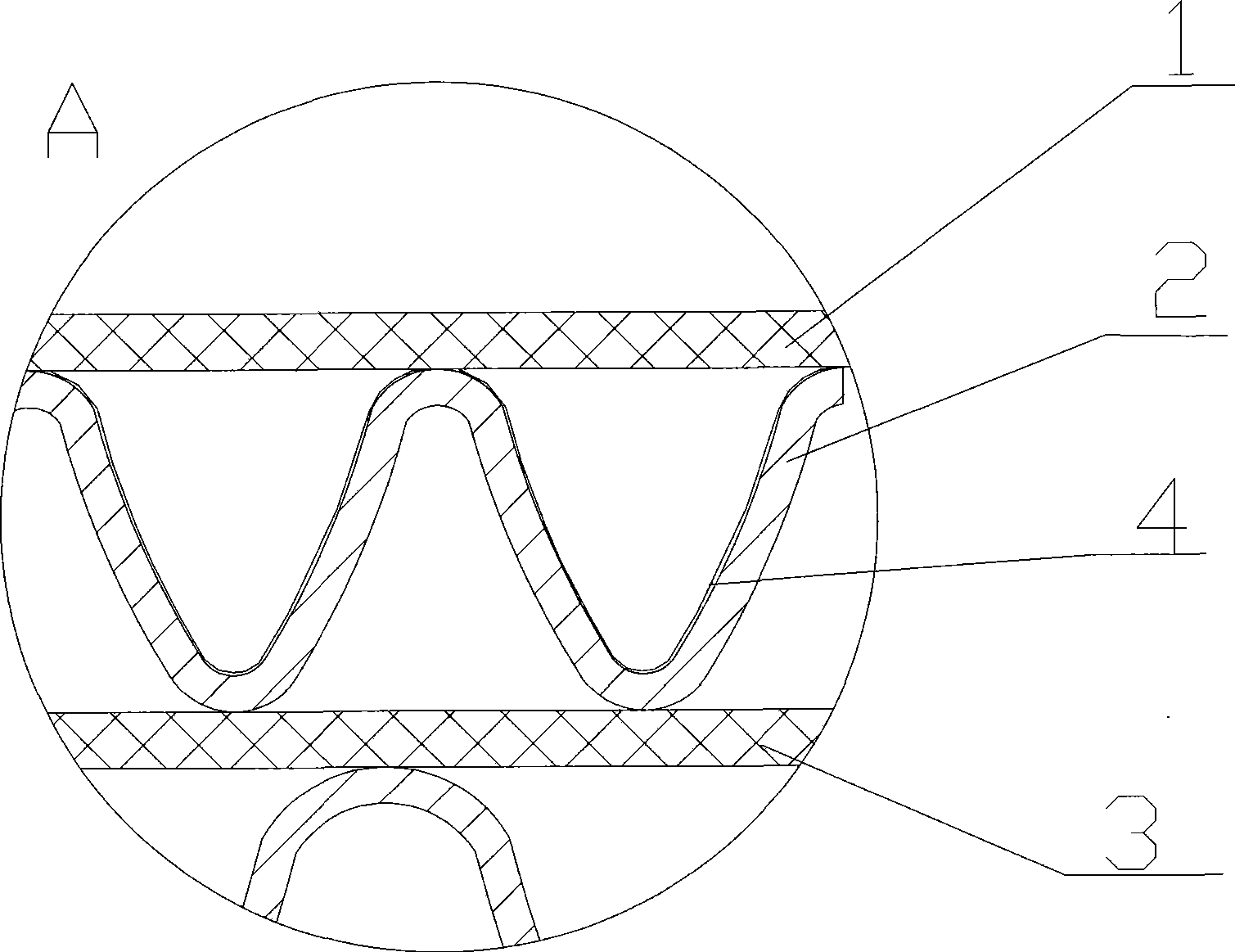

[0056] Such as figure 1 and figure 2 As shown, the anti-counterfeiting corrugated cardboard is a five-layer double corrugated cardboard, which is composed of upper and lower layers of paper 1, core paper 3 and two corrugated papers 2 bonded between the surface paper and the core paper. The adhesive surface 4 of the corrugated paper is coated with There are inks of specific colors. The ink layer is coated on the bonding surface of the port edge of the corrugated box, and the color band width is 4-5cm.

[0057] The corrugated cardboard is completed by the BHS 2.8m super-large "cardboard automatic assembly line" imported from Germany, which can be produced continuously at high speed.

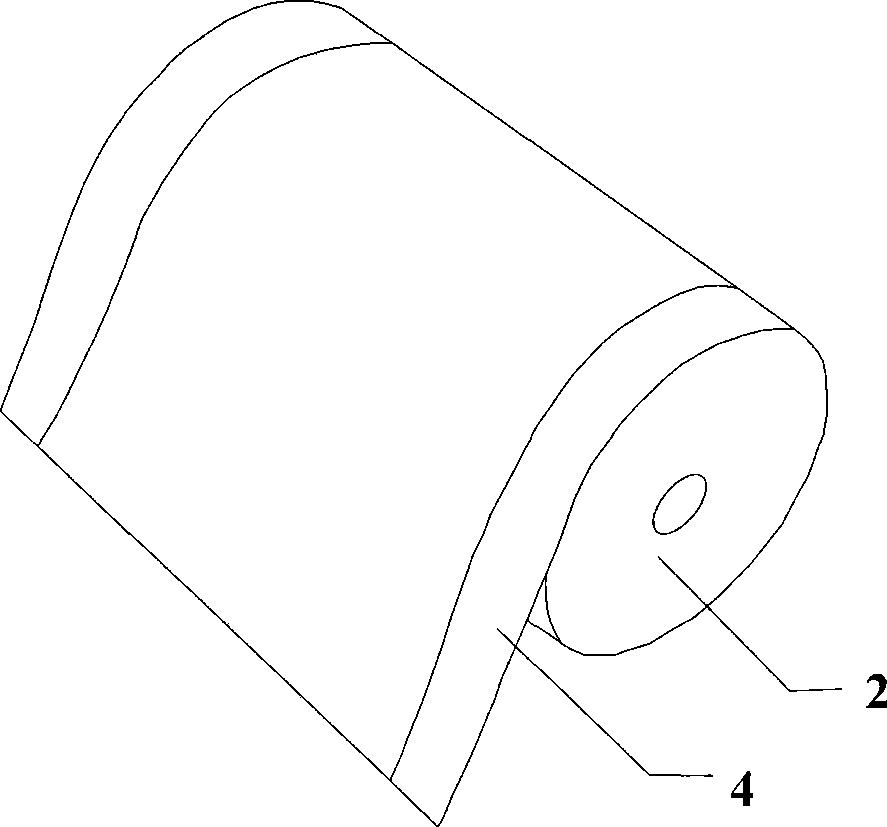

[0058] Such as image 3 , the entire roll of corrugated base paper 3 (each roll weighs about 1 ton) is first coated with ink of a specific color on the coating machine, which can be coated on one side (or t...

Embodiment 2

[0060] Example 2 5-layer anti-counterfeit double corrugated carton and its preparation

[0061] Such as Figure 5 , the 5-layer anti-counterfeit double corrugated cardboard box is made of 5 layers of anti-counterfeit double corrugated cardboard after printing, crimping, slotting, corner cutting and joining. Its cartons can be completed on the "printing and slotting unit" or "printing and die-cutting unit" or other equipment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com