Bidimensional small angle measuring device based on shape of interference fringe

An angle measurement device and technology of a measurement device, applied in the field of precision measurement, can solve problems such as large volume, required load engraving, complex structure, etc., and achieve the effect of strong anti-interference ability, less optical components, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

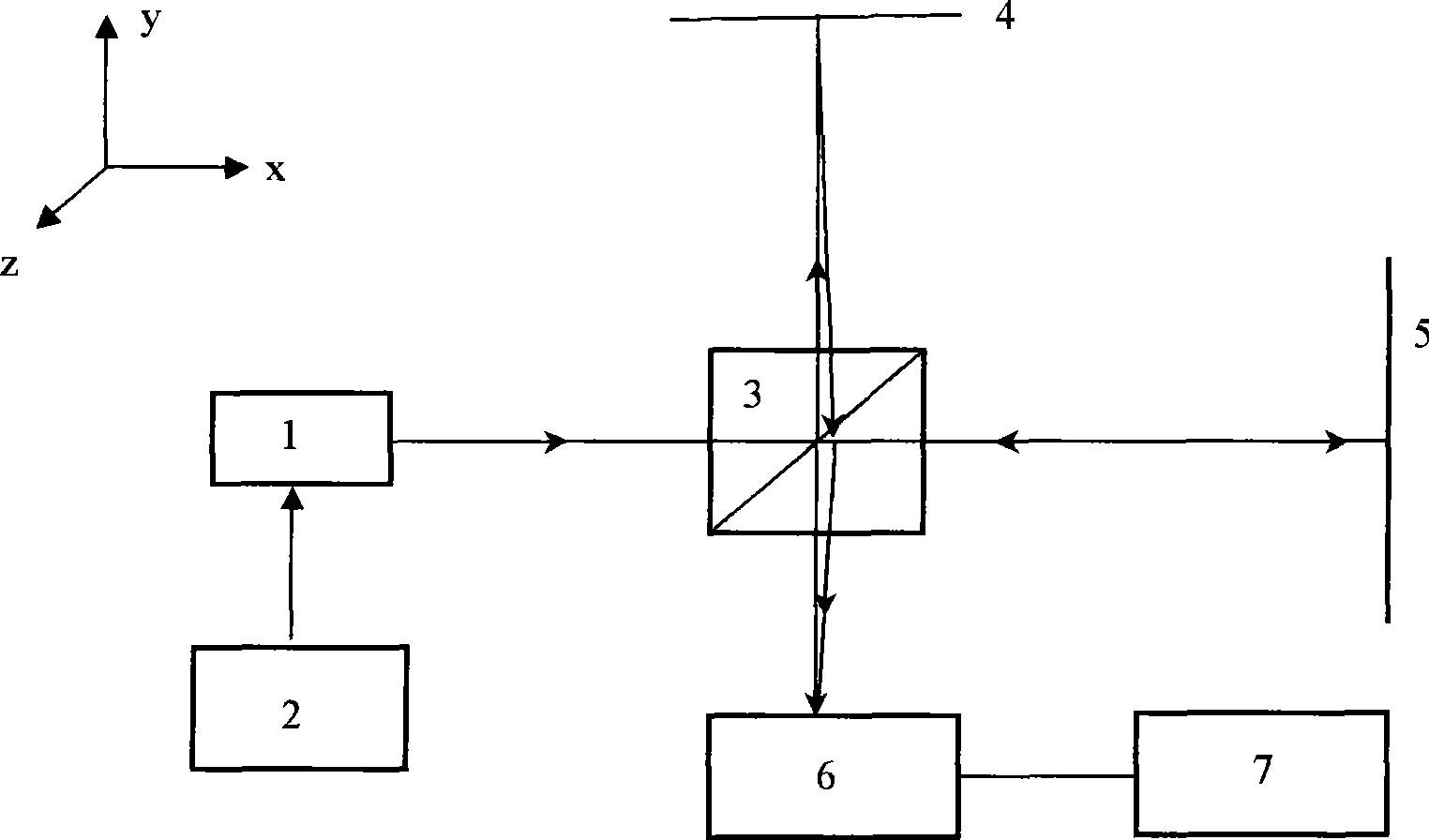

[0010] The structure and measurement principle of the optical system of the present invention will be described in further detail below in conjunction with the accompanying drawings.

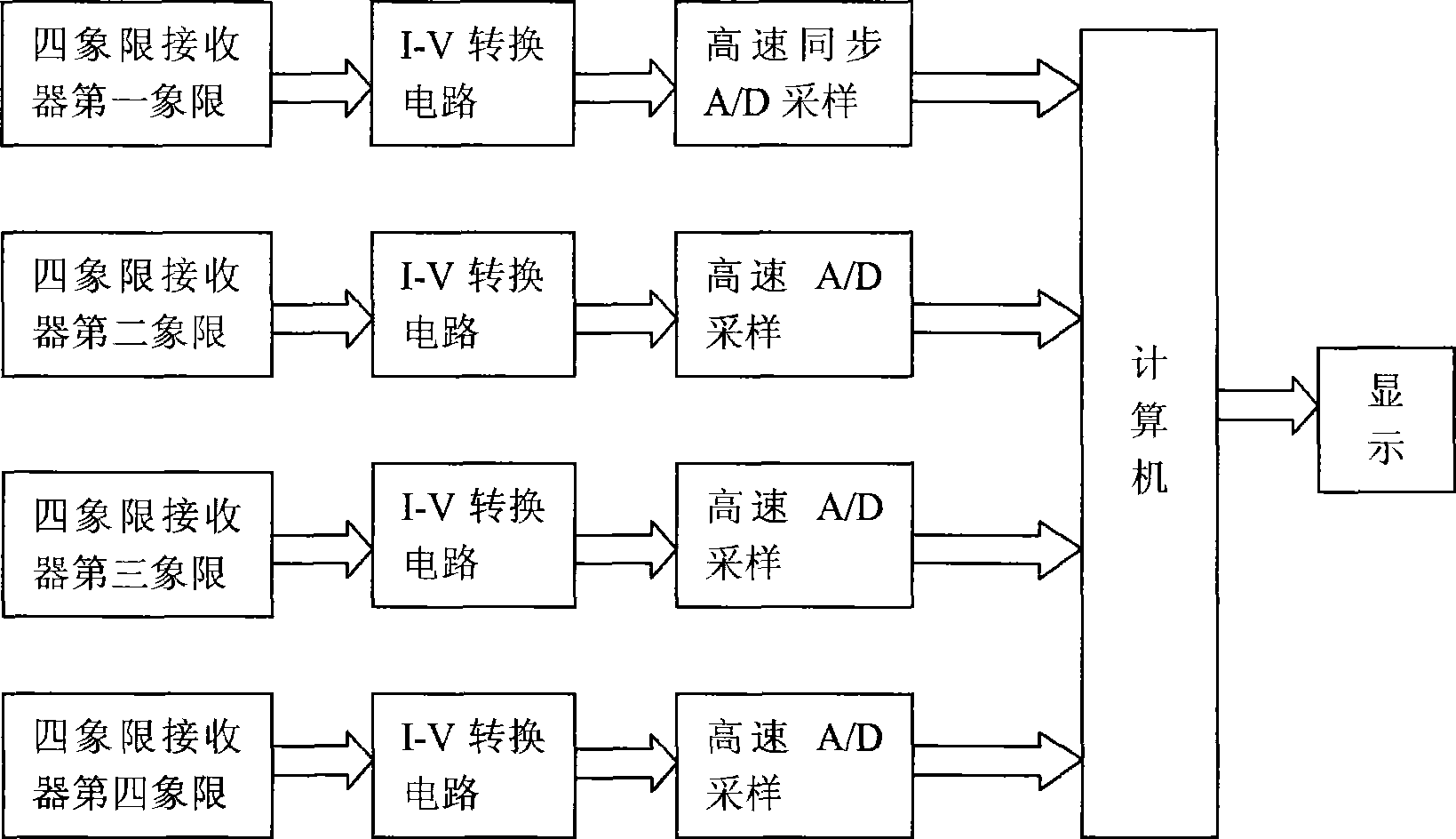

[0011] Such as figure 1 As shown, a semiconductor laser is used in this embodiment, and the laser 1 may also be another type of laser, such as a He-Ne laser. The laser modulator 2 is used to modulate the laser. The modulation signal can be a triangular wave, a sawtooth wave or a sine wave. In this way, the wavelength and intensity of the beam emitted from the laser periodically change with the modulation signal. The beam is split by the beam splitter 3. There are two beams, one beam is incident on the reference mirror 5, the reflected light passes through the beam splitter 3, the other beam is incident on the mirror 4 fixed on the surface of the object to be measured, and the beam reflected from the mirror 4 is then split After the mirror 3 and the light reflected from the mirror 5, interference fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com