A composite fiber modular bio-filler and its layout method used for sewage treatment

A technology of composite fiber and biological filler, which is applied in biological water/sewage treatment, water/sludge/sewage treatment, sustainable biological treatment, etc., and can solve problems such as limited application and weak impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The specific steps of a method for arranging a composite fiber biological filler for sewage treatment are:

[0030] 1) Production of modular packing:

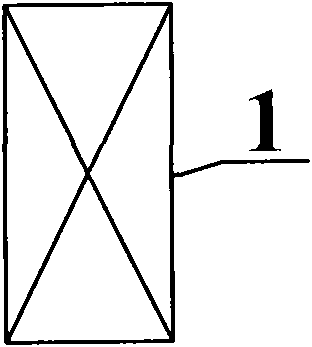

[0031] The first step: the production of the frame, welding the stainless steel 304 square tube with a specification of Ф15×15×1.5 into a 2000×1200mm stainless steel frame 1, welding diagonal braces in the frame to make the structure stable, and the material of the diagonal braces Same as framework ( figure 1 );

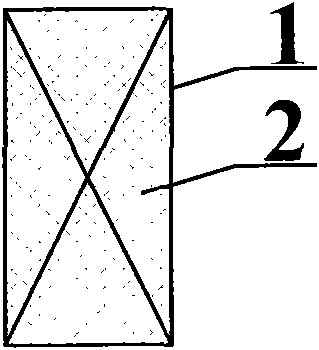

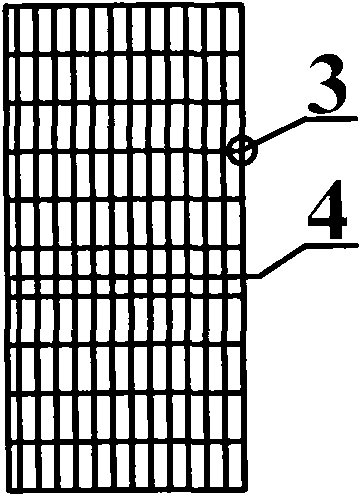

[0032] The second step: the production of polyamide net, prepare 12 long 1200mm, the polyester cloth strip 3 of wide 20mm, the polyamide fiber 4 (120D / 36F) of long 2000mm is turned on the polyester cloth strip 3 with sewing machine ( figure 2 , image 3 );

[0033] The third part; the making of polyester mesh, the same size and manufacturing method as polyamide fiber mesh 5 ( figure 2 , image 3 );

[0034] The fourth step: the production of filling ( figure 2 , Figure 4 ), put the polyamide fiber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com