Method for clean purifying L-tryptophan by utilizing fermented liquid

A technology for tryptophan and fermentation broth, applied in organic chemistry and other directions, can solve the problems of vacuum concentration for a long time, high energy consumption, damage and other problems, and achieve the effects of shortening purification time, reducing pollution and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

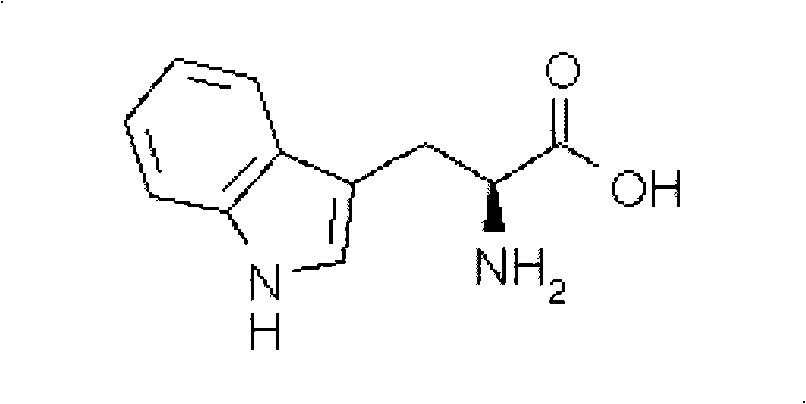

Image

Examples

Embodiment Construction

[0030] The method for cleaning and purifying L-tryptophan by utilizing the fermented liquid sequentially includes (1) a crude product preparation process; (2) a pure product preparation process; the crude product preparation process is carried out in sequence as follows:

[0031] (1.1) Microfiltration (MF): Ceramic membranes are used to sterilize the fermentation broth. In the process of filtering through the ceramic membrane, the volume of the top water is 2 to 4 times of the volume of the residual liquid in the ceramic membrane, preferably 2.5 to 3 times; the volume of the top water means that the fermentation liquid runs in the ceramic membrane to its After the dead cycle volume, add a certain volume of water to further elute the residual product in the ceramic membrane.

[0032] The use of ceramic membranes can remove bacteria, macromolecular organic matter and solid suspended matter in the fermentation broth. The top water volume has a great influence on the yield of cera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com