Monodisperse C* nano unit crystal material and method for preparing same

A nano-single-crystal, monodisperse technology, applied in the direction of polycrystalline material growth, single crystal growth, single crystal growth, etc., can solve problems such as disorder, difficulty, and lack of high crystallinity, and achieve a promising, Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

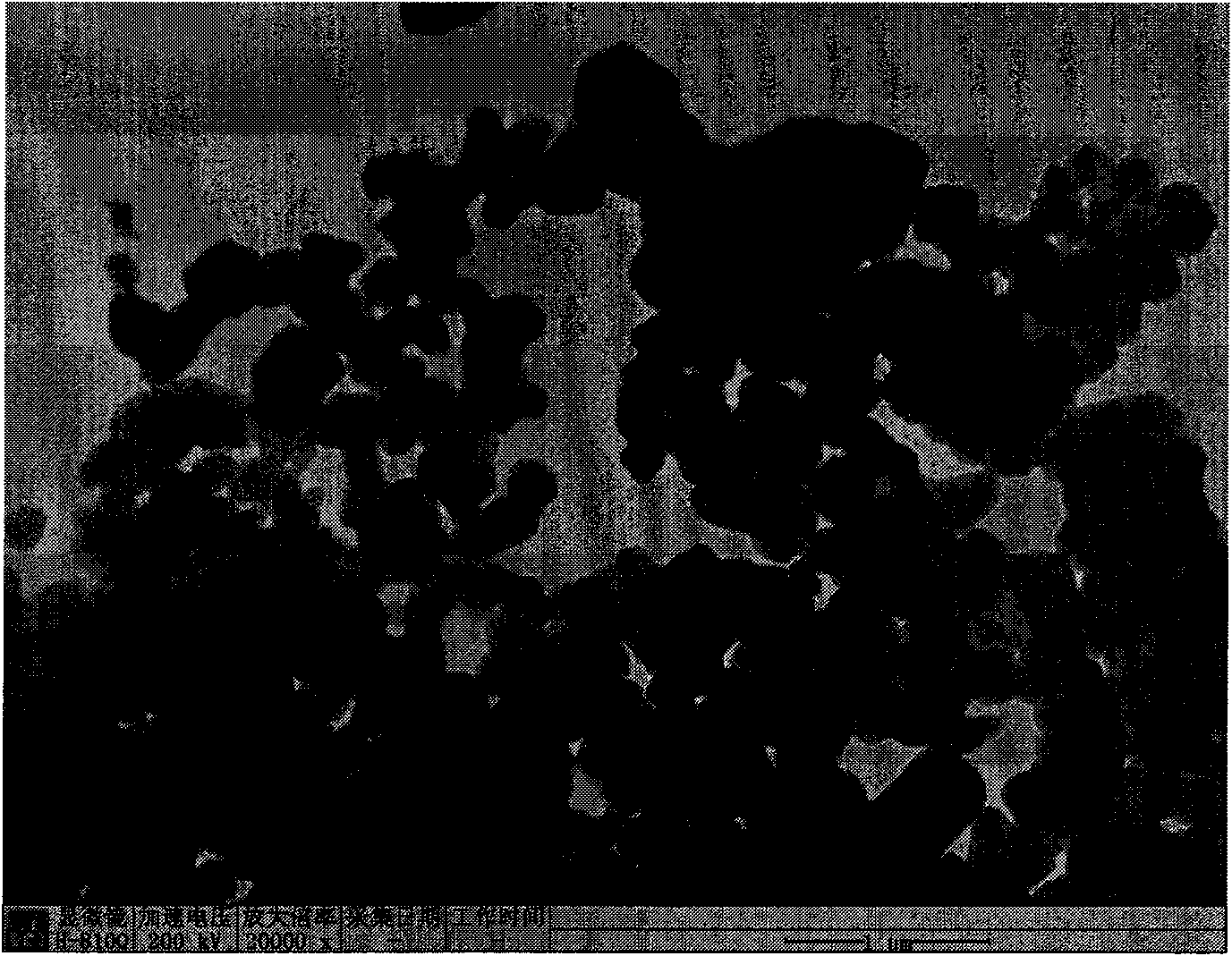

[0027] Embodiment 1 provides a specific preparation granular C 70 Examples of nano single crystals.

[0028] Choose saturated C 70 Meta-xylene solution was used as the mother liquor, and methanol was selected as the shape regulator. Will C 70 The saturated m-xylene solution and methanol were mixed with each other at a volume ratio of 1:8, added to a glass weighing bottle, ultrasonically oscillated for 30 seconds, and left to stand at room temperature for 2 hours. Use a rubber dropper to suck out the sediment at the bottom of the container, drop it on a substrate such as a silicon wafer or a glass wafer, and naturally volatilize the solvent and shape regulator at room temperature, and then obtain granular C with a diameter of 200-300 nm on the substrate. 70 nanocrystals. at 10 -5 Under the pressure of Pa, at a temperature of 120 ° C, the solvent is removed by heating to obtain C with a face-centered cubic structure. 70 Nanoparticles are single crystals that remain unchang...

Embodiment 2

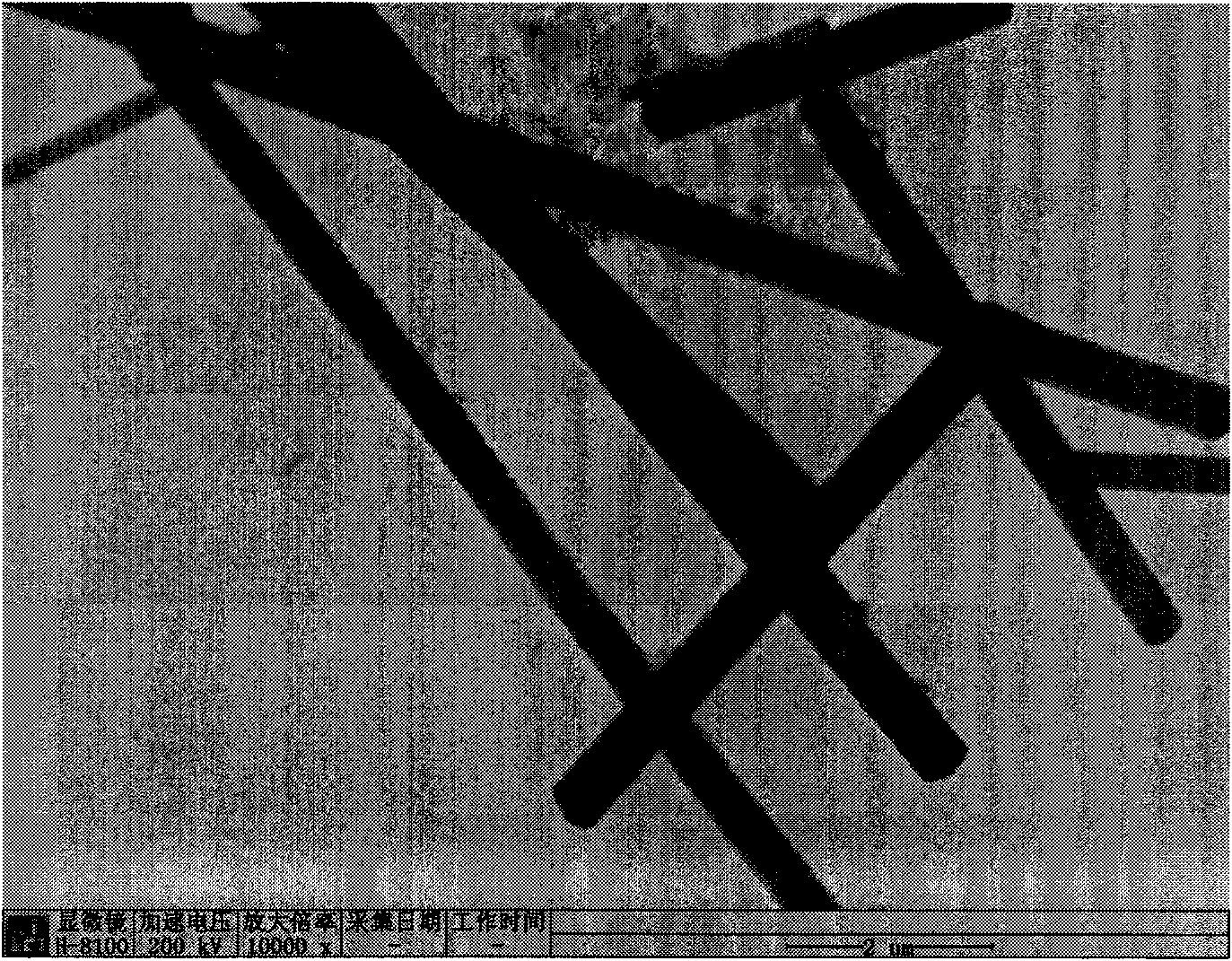

[0029] Embodiment 2 provides a specific preparation granular C 70 Examples of nano single crystals.

[0030] Choose saturated C 70 The m-xylene solution is used as the mother liquor, and n-butanol is used as the shape regulator. Will C 70 A saturated solution of m-xylene and n-butanol were mixed with each other at a volume ratio of 1:10, added to a glass weighing bottle, ultrasonically oscillated for 60 seconds, and left to stand at room temperature for 5 hours. Use a rubber dropper to suck out the sediment at the bottom of the container, drop it on a substrate such as a silicon wafer or a glass sheet, and naturally volatilize the solvent and shape regulator at room temperature, and then obtain granular C with a diameter of 400-600 nm on the substrate. 70 nanocrystals. at 10 -5 Under the pressure of Pa, at a temperature of 150 ° C, the solvent is removed by heating to obtain granular C with a face-centered cubic structure. 70 Nano single crystal, shape and size remain un...

Embodiment 3

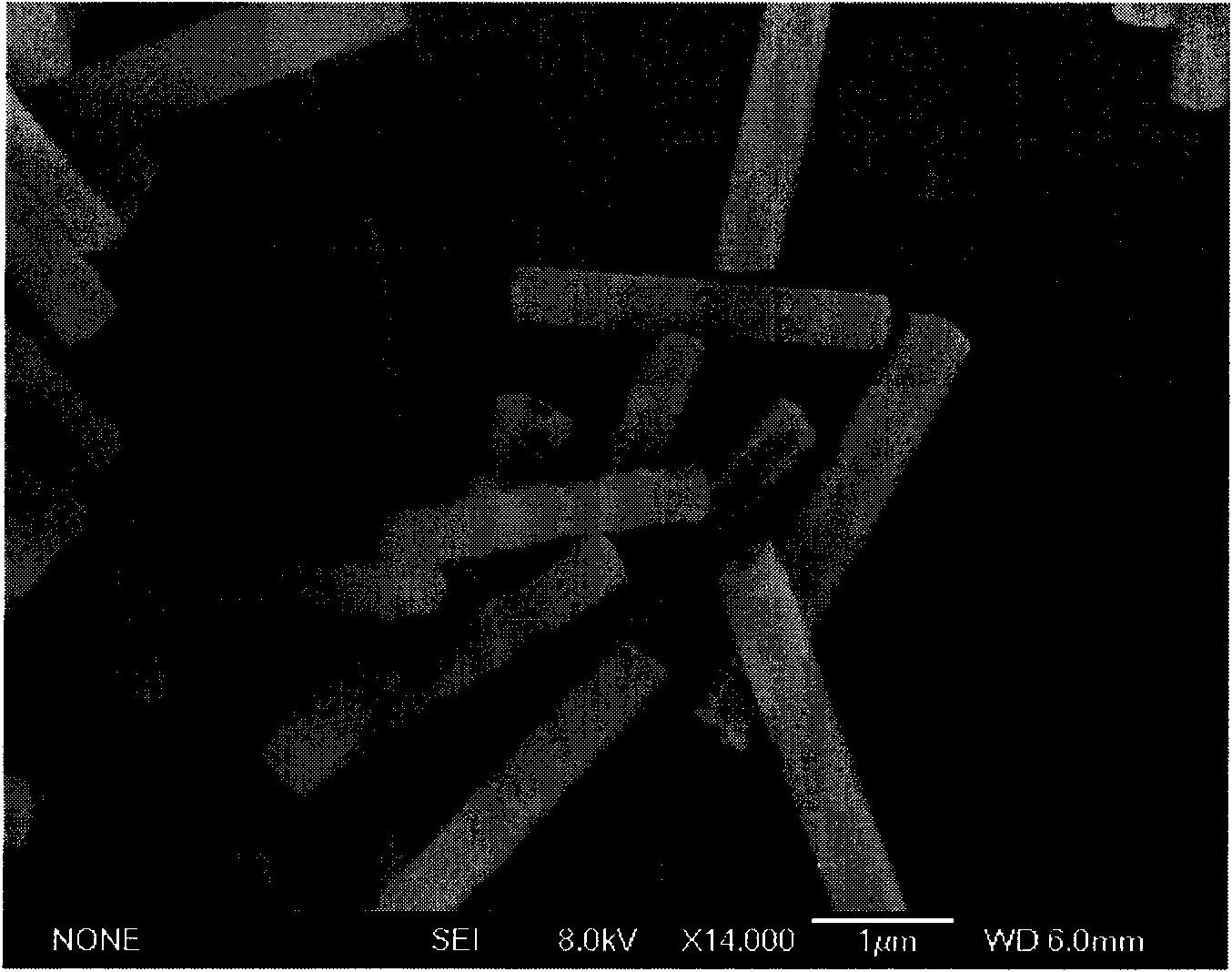

[0031] Embodiment 3 provides a specific preparation granular C 70 Examples of nano single crystals.

[0032] Choose saturated C 70 The m-xylene solution is used as the mother liquor, and n-amyl alcohol is used as the shape regulator. Will C 70 Saturated m-xylene solution and n-amyl alcohol were mixed with each other at a volume ratio of 1:10, added to a glass weighing bottle, ultrasonically oscillated for 30 seconds, and left to stand at room temperature for 10 hours. Use a rubber dropper to suck out the sediment at the bottom of the container, drop it on a substrate such as a silicon wafer or a glass sheet, and naturally volatilize the solvent and shape regulator at room temperature, and then obtain granular C with a diameter of 400-600 nm on the substrate. 70 nanocrystals. at 10 -5 Under the pressure of Pa, at a temperature of 140 ° C, the solvent is removed by heating to obtain granular C with a face-centered cubic structure. 70 Nano single crystal, shape and size rem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com