Anion ecological floor and process for producing same

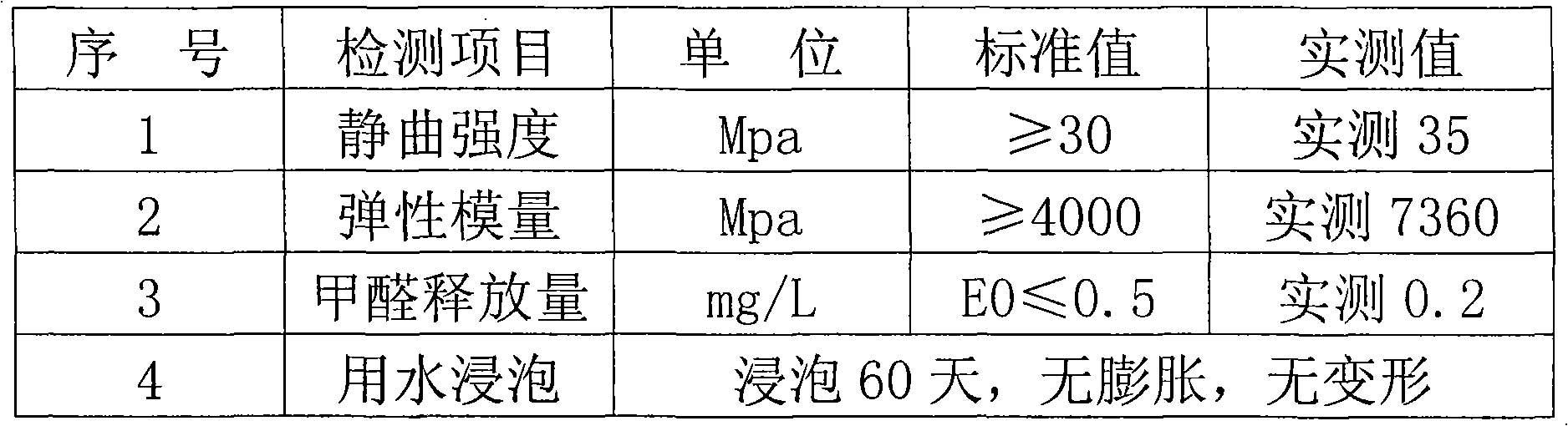

A negative ion and ecological technology, applied in the direction of floors, buildings, building structures, etc., can solve the problems of fire fear, pollution, waste of resources and other environmental problems, and achieve the effect of strong water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The negative ion ecological floor provided by the present embodiment is made of the following raw materials in parts by weight:

[0026] (1) Waste PVC powder: 100 parts;

[0027] (2) Waste tailings sand: 150 parts;

[0028] (3) 12 parts of tourmaline tailing powder;

[0029] (4) Auxiliary: 9.2 parts, including: 0.8 part of plasticizer (DOP), 3.8 part of heat stabilizer (JX-03S-5), 1.0 part of lubricant (paraffin), 1.2 part of flame retardant (TBBPA) , 2.4 parts of stearic acid (1801).

[0030] The above-mentioned waste PVC, namely waste polyvinyl chloride, is ground to 60-100 mesh. The amount of waste PVC powder added should be strictly controlled within the range specified in the present invention. Since the quality of waste PVC powder fluctuates greatly, the proportion should be adjusted according to the quality of waste PVC.

[0031] The above-mentioned waste tailing sand includes iron ore, calcium carbonate, stone powder, slag, etc., and its chemical composition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com