Mosquito killing Bacillus sphaericus leafing agent and preparation method thereof

A Bacillus sphaericus and mosquito-killing technology, which is applied in the field of preparation of biological preparations, can solve the problems of high energy consumption, high cost, and large potency loss of Bacillus sphaericus, and achieve low potency loss rate and low transportation cost , the effect of small energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

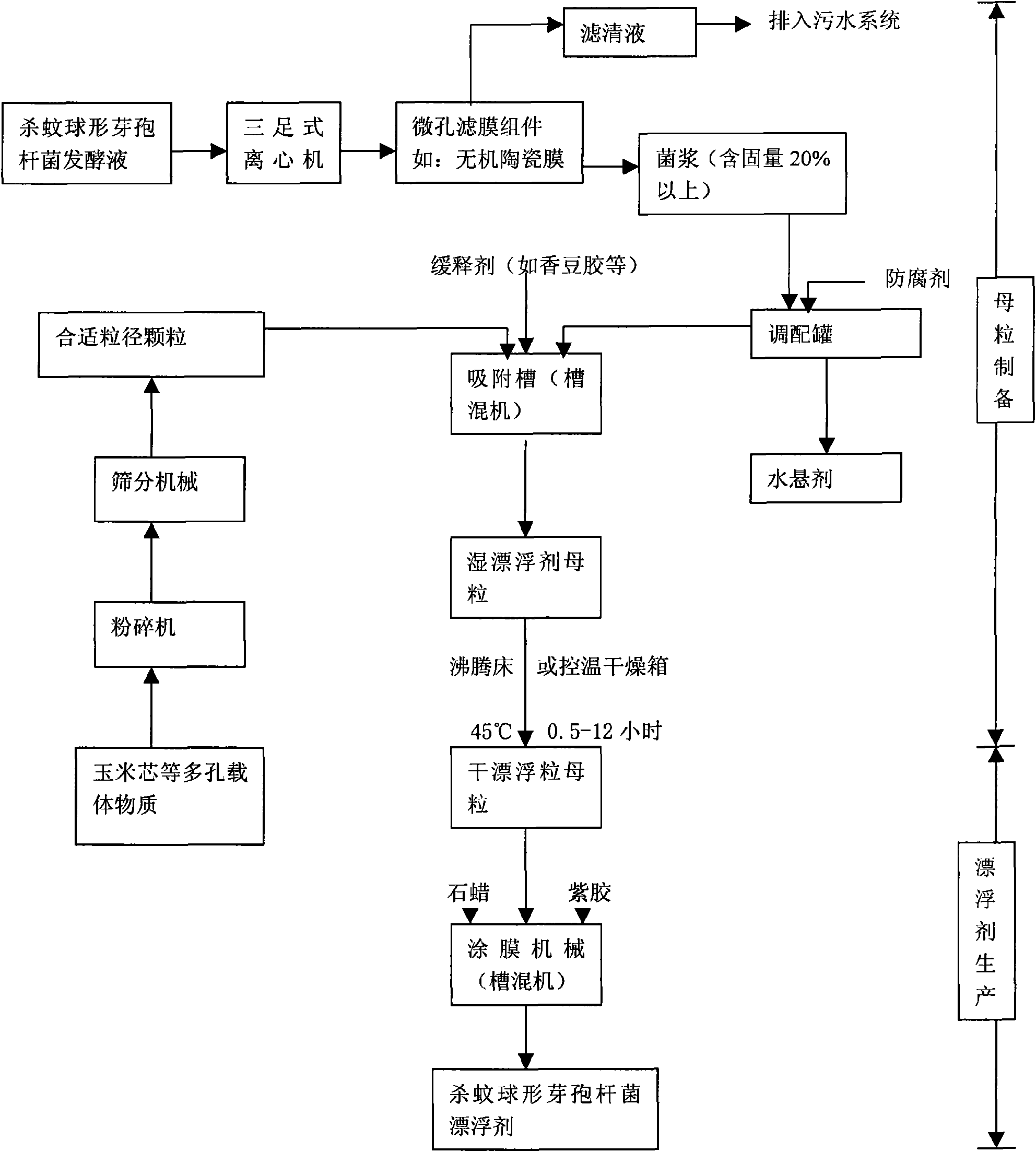

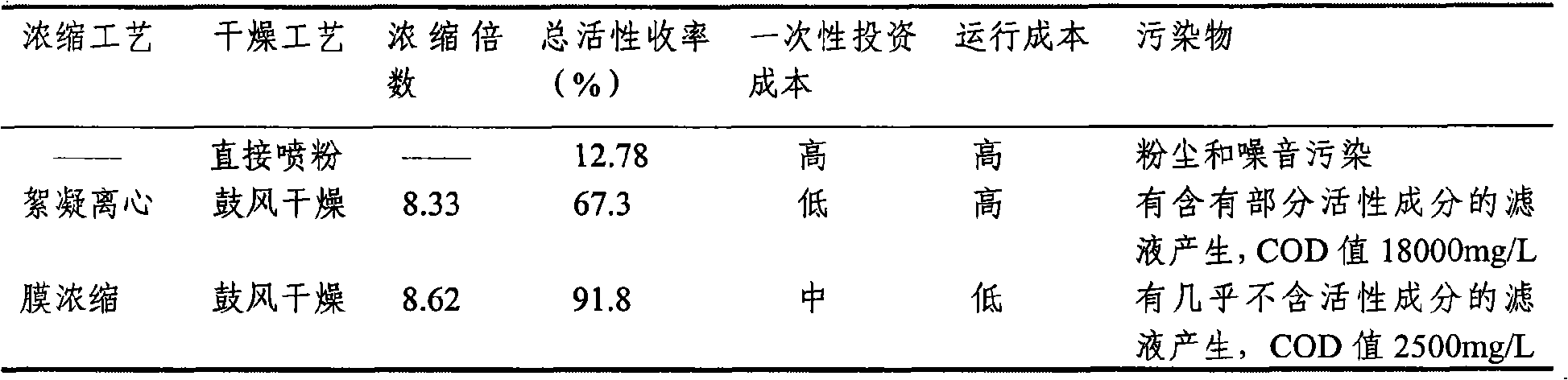

Method used

Image

Examples

Embodiment 1

[0032] After the mosquito-killing Bacillus sphaericus is successfully fermented, hydrochloric acid is added to adjust the pH to 5.0, and the slag is removed through a three-legged centrifuge (the screen mesh is 60 mesh, and the centrifuge speed is 1000 rpm). Take 75kg of fermentation filtrate, the power is 45w, the membrane area is 0.3m 2 , concentrated in an inorganic ceramic membrane module with a membrane pore size of 100nm, the operating temperature is 35°C, and the operating time is 6 hours and 25 minutes. After concentration, 66.3kg of clear liquid is discharged, and the bacteria slurry is released, and the bacteria remaining in the membrane and the pipeline are rinsed with a little water. Slurry, collect 8.6kg of bacterial slurry, and adjust the pH value to 4.8 with dilute hydrochloric acid simultaneously. Add the bacterium slurry to 0.67kg of dry corn cob particles with a particle size of 1-2mm in a weight ratio of 7.8%, fully mix the two in a tank mixer, and then diss...

Embodiment 2

[0035] After the mosquito-killing Bacillus sphaericus is successfully fermented, hydrochloric acid is added to adjust the pH to 5.0, and the slag is removed through a three-legged centrifuge (the screen mesh is 40 mesh, and the centrifuge speed is 1000 rpm). Take 75kg of fermentation filtrate, the power is 45w, the membrane area is 0.3m2 , concentrated in an inorganic ceramic membrane module with a membrane pore size of 100nm, the operating temperature is 36°C, and the operating time is 6 hours and 20 minutes. After concentration, 66.6kg of clear liquid is discharged, and the bacterial slurry is released, and the bacterial slurry remaining in the membrane and the pipeline is washed with a little water. , collect 8.5 kg of bacterial slurry, and adjust the pH value to 4.8 with dilute hydrochloric acid. Add 2.0124 kg of perlite particles to the bacterium slurry by weight ratio of 23.4%, fully mix the two in a tank mixer, then dissolve 68.8 g of coumarin in 1.4 L of clear water to ...

Embodiment 3

[0038] After the mosquito-killing Bacillus sphaericus is successfully fermented, hydrochloric acid is added to adjust the pH to 5.0, and the slag is removed through a three-legged centrifuge (the screen mesh is 60 mesh, and the centrifuge speed is 1000 rpm). Take 75kg of fermentation filtrate, the power is 45w, the membrane area is 0.3m 2 , concentrated in an inorganic ceramic membrane module with a membrane pore size of 100nm, the operating temperature is 37°C, and the operating time is 6 hours and 18 minutes. After concentration, 66.5kg of clear liquid is discharged, and the bacterial slurry is released, and the bacterial slurry remaining in the membrane and the pipeline is washed with a little water. , collect 8.6kg of bacterial slurry, and adjust the pH value to 4.8 with dilute hydrochloric acid. Add the bacterium slurry to 0.7432kg of dry corn cob particles with a particle size of 1-2mm at a weight ratio of 9.0%, fully mix the two in a tank mixer, and then dissolve 68.8g ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com