Method for preparing nano-scale silver powder

A nano-scale, silver powder technology, applied in the field of liquid-phase preparation of nano-scale silver powder, can solve the problems that cannot meet the needs of the electronics industry, unsolved agglomeration problems, self-sintering or agglomeration, etc., to achieve reduced silver consumption, easy size adjustment, and drying temperature wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

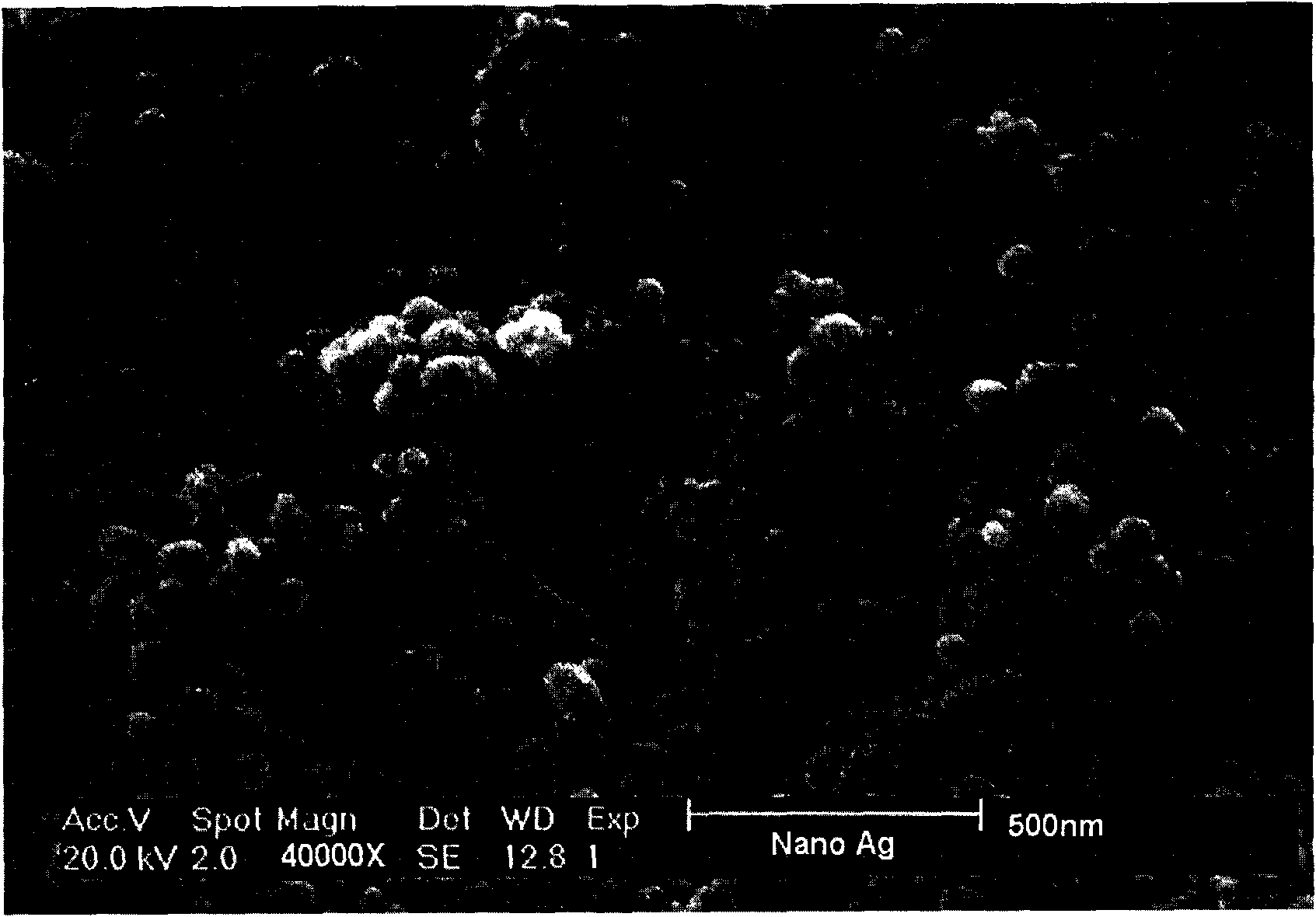

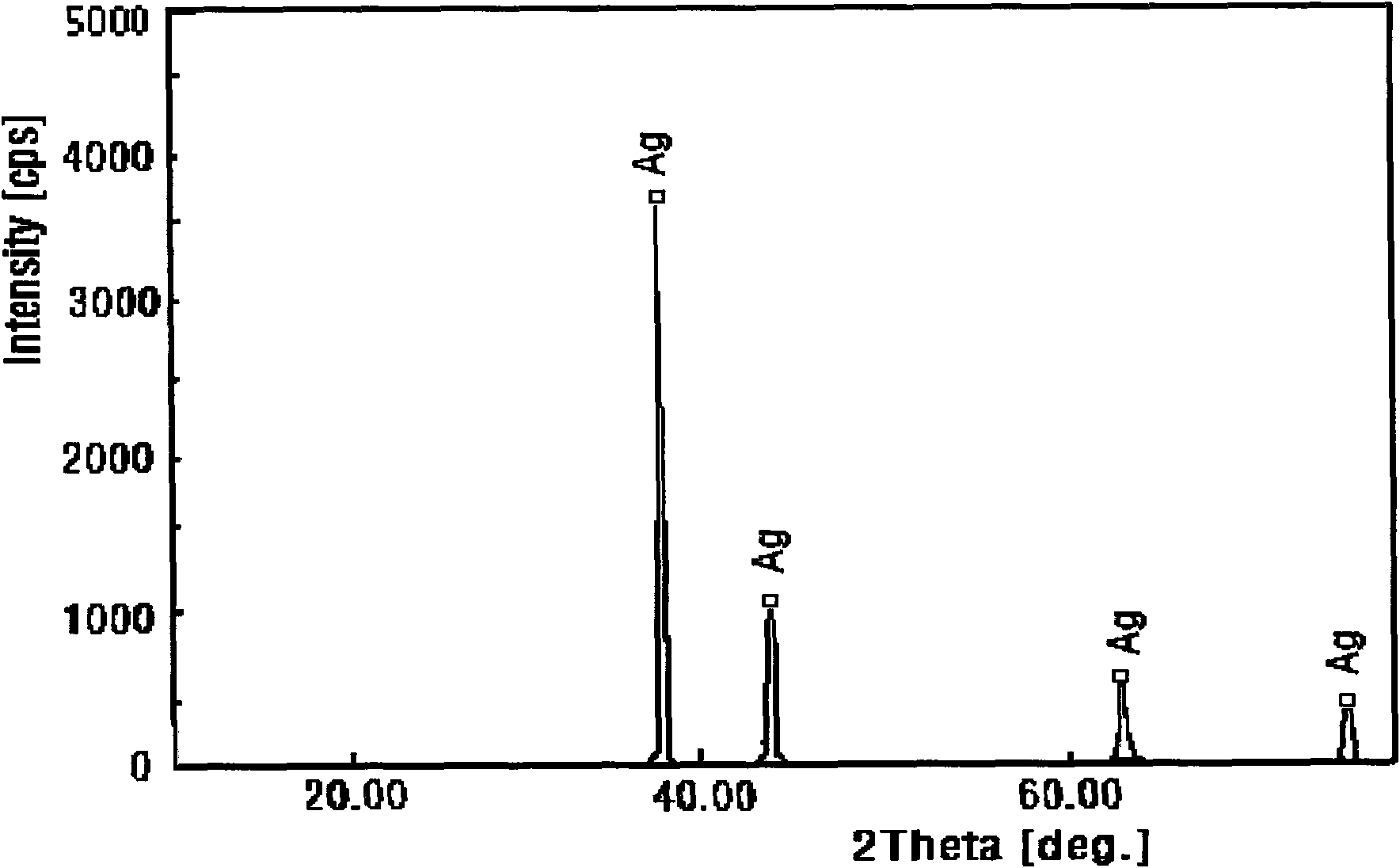

[0013] Dissolve 157g of silver nitrate in 1L of water, and add 50g of ammonia water while stirring to obtain a silver-containing aqueous solution. Add 30 mL of hydrazine hydrate to 1 L of water, adjust the pH to 12 with NaOH, add 10 g of polyvinylpyrrolidone and 4 g of oleic acid, and stir evenly to obtain a reducing solution. Stir mechanically, control the reaction temperature at 35±3°C, drop the silver-containing aqueous solution into the reducing solution within 2 hours, and add NaOH solution dropwise at the same time to control the reaction pH value to 12±0.5, and then stir for 10 minutes after the addition is completed to obtain black nano Silver suspension, continue to stir, add nitric acid dropwise until the pH value of the suspension is 6, stir for another 20 minutes, then let it stand for precipitation, wash the powder with pure water until the conductivity of the filtrate is reached, then soak and wash the powder with ethanol once, filter to dry, dry at 70°C, and siev...

Embodiment 2

[0015] Except that oleic acid was changed to linoleic acid, other materials, dosage and process were consistent with Example 1. Powder test results: tap density 2.56g / ml, specific surface area 3.358m 2 / g, the average particle size of the particles is 102nm, and the XRD analysis is 100% Ag.

Embodiment 3

[0017] Except changing 50g of ammonia water into 10g of ethylenediaminetetraacetic acid disodium salt, other materials, consumption and process are consistent with embodiment 1. Powder test results: tap density 2.44g / ml, specific surface area 3.971m 2 / g, the average particle size of the particles is 81nm, and the XRD analysis is 100% Ag.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tap density | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com