Technology for processing and recycling electroplating wastewater containing cyanide and system thereof

A cyanide wastewater and process technology, which is applied to the treatment and reuse process of electroplating cyanide-containing wastewater and its system field, can solve the problems of unsatisfactory wastewater treatment effect, poor recycling effect, and high energy consumption, and achieve compact structure, Ease of assembly and simplification of the operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

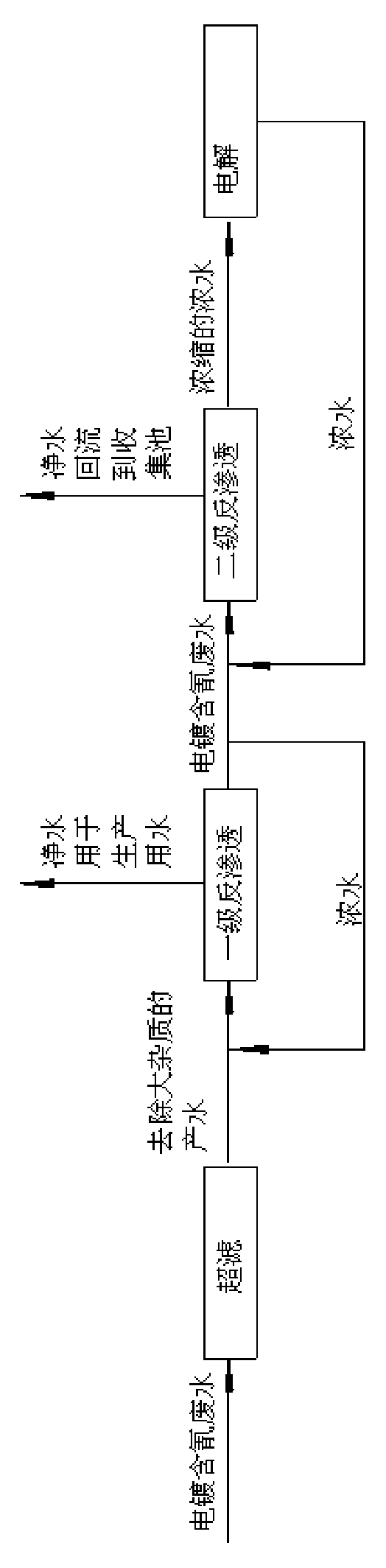

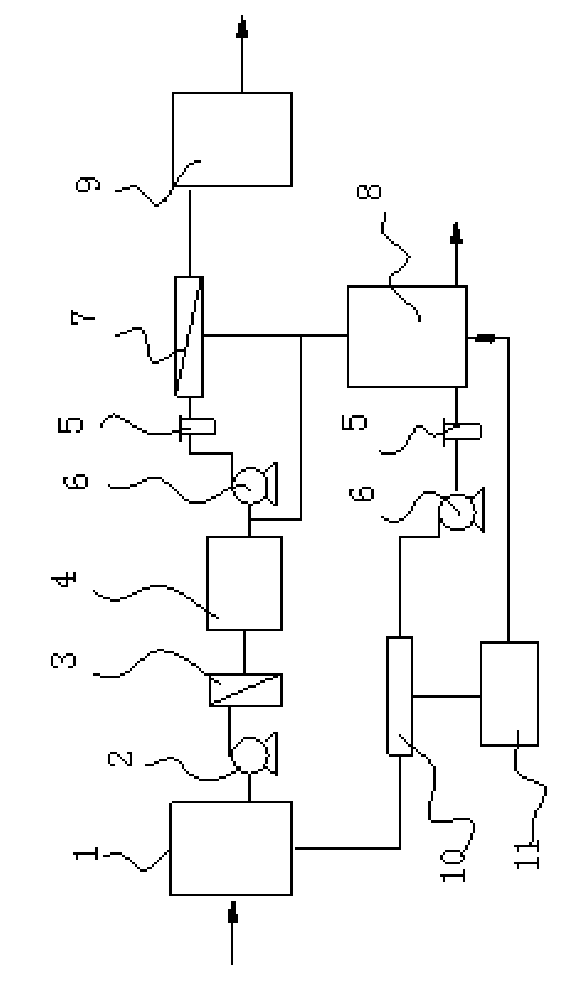

[0025] Such as figure 1 Shown, a kind of treatment and recycling process of electroplating cyanide-containing wastewater, it comprises the following steps: (1) carry out the pretreatment of electroplating cyanide-containing wastewater by ultrafiltration, remove larger impurity in the wastewater; (2) after pretreatment After the filtered water is treated with one-stage reverse osmosis, cyanide substances and heavy metal salt-containing substances cannot pass through the reverse osmosis membrane, and are trapped in concentrated water, and the produced water is recycled for production use; (3) it will pass through one-stage reverse osmosis The treated primary reverse osmosis concentrated water containing cyanide and heavy metals is treated by secondary reverse osmosis. The secondary reverse osmosis concentrates the primary reverse osmosis concentrated water by 8-12 times, and the product water is recycled for production use; (4 ) will carry out electrolytic treatment to the conce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com