Passivant for inhibiting iron and aluminium impurity acid split leaching of phosphorite and operation method thereof

A passivating agent and phosphate rock technology, applied in the field of acid hydrolysis of phosphate rock, can solve the problems of large acid consumption, difficult cleaning, easy clogging of equipment by sludge, etc., and achieve the effect of inhibiting leaching of iron and aluminum impurities and high leaching rate

Inactive Publication Date: 2009-10-14

SICHUAN UNIV

View PDF3 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] In view of the deficiencies in the prior art, the purpose of the present invention is to provide a passivator that can effectively inhibit the leaching of iron and aluminum impurities during the acid hydrolysis of phosphate rock, and to use the passivator to control the leaching of iron and aluminum impurities during the acid hydrolysis of phosphate rock. Process leaching process to solve the problem of acid hydrolysis of phosphate rock in the prior art due to the large amount of acid consumption and phosphorus loss caused by the large amount of iron and aluminum impurities entering the liquid phase, it is difficult to produce high-quality phosphoric acid from high-iron-aluminum phosphate rock, and The sludge formed by iron and aluminum impurities in the phosphoric acid storage tank is easy to block the equipment, and it is difficult to clean up and many other problems

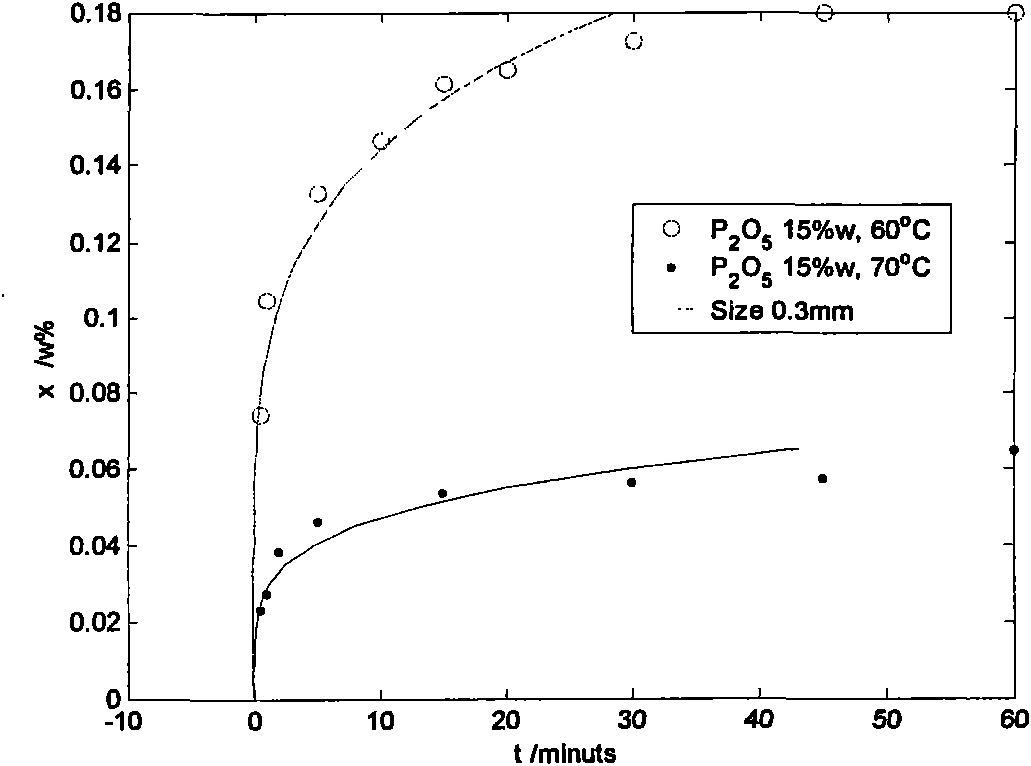

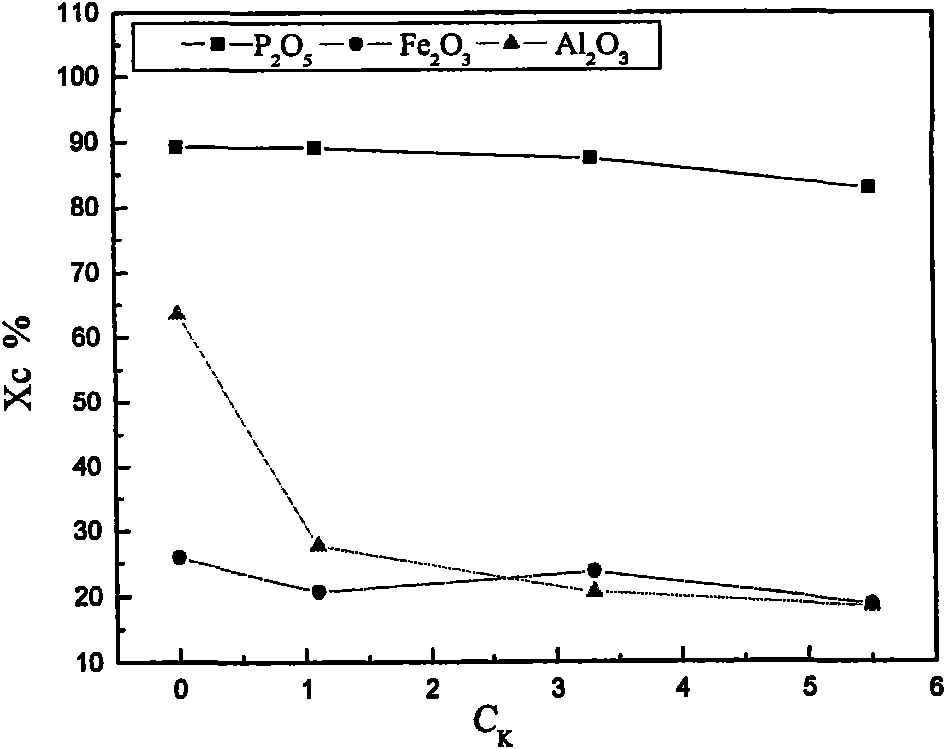

[0005] In order to solve the problems caused by the leaching of iron and aluminum impurities in the acid hydrolysis process of high-iron aluminum phosphate rock, the present invention adopts a new idea, that is, adding a passivating agent during the acid hydrolysis reaction process of phosphor rock to degrade the iron in the phosphor rock particles. Selective passivation treatment is carried out for aluminum impurities. Under the premise of not affecting the conversion of phosphorus, the iron and aluminum impurities are suppressed in the phosphate rock as much as possible, and are filtered out with the phosphogypsum solid residue, so that they enter the liquid during the acidolysis process. The amount of phase is reduced, so as to achieve the purpose of improving the quality of phosphoric acid, so as to find an optimal route for wet treatment process suitable for this kind of phosphate rock

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0028] Sodium hexametaphosphate 25w%, sodium nitrate 20w%, sodium tripolyphosphate 10w%, sodium hydrogen phosphate 20w%, 2-benzoyl 3-hydroxypropene 25w%.

Embodiment 2

[0030] Sodium tripolyphosphate 40w%, nitric acid 15w%, thiourea 45w%.

Embodiment 3

[0032] Sodium trimetaphosphate 20w%, ammonium nitrate 15w%, sodium tripolyphosphate 20w%, zinc phosphate 15w%, o-xylylthiourea 30w%.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a passivant for inhibiting iron and aluminium impurity leaching during acid splitting process of phosphorite; the invention also discloses an operation method for controlling iron and aluminium impurity leaching of phosphorite by passivant. The passivant mainly comprises components distributed according to weight percentage as follows: 20-50%w of polyphosphates, 10-30w % of at least one selected from nitric acid, nitrate and acetic acid, and 30-60%w of sulfur nitrogen compound. The method for controlling iron and aluminium impurity leaching of phosphorite by passivant comprises adding passivant with a weight content which is not larger than that of sesquioxide R2O3 in the phosphorite during the acid splitting process of the phosphorite. The passivant of the invention is used in acid splitting process of phosphorite to effectively inhibit iron and aluminium impurity leaching while maintaining a high leaching rate of effective phosporus component, thereby solving a plurality of problems caused by entering of excess iron and aluminium impurity into the liquid phase in the acid splitting process of phosphorite of prior art.

Description

technical field [0001] The present invention relates to the technical field of phosphate rock acid hydrolysis, more specifically, relates to a passivating agent capable of inhibiting the leaching of iron and aluminum impurities in phosphate rock during the acid hydrolysis reaction process of phosphate rock, and using the passivator to control the iron and aluminum in phosphate rock The method of impurity leaching. Background technique: [0002] With the massive development of the phosphorus chemical industry, high-grade phosphate rock resources are gradually being exhausted. In order to maintain the survival and development of phosphorus chemical enterprises and meet people's demand for phosphorus chemical products, countries all over the world are scrambling to develop and utilize low-grade and medium-grade phosphate rock resources. New technology for phosphate rock. The inventor of the present invention has been paying attention to the development and utilization of low- ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22B3/06C22B3/08C23C22/23

CPCY02P10/20

Inventor 刘代俊杨军

Owner SICHUAN UNIV

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com