Electrospark hardening method of surface of metal roll

A roll surface, electric spark technology, applied in the metal material coating process, fusion spraying, coating, etc., can solve the problems of easy fatigue and peeling of the coating, high production cost, large equipment investment, etc., to improve the surface quality, Improved service life and simple process equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1. The output power and output voltage determine the spark discharge energy, which has a great influence on the thickness of the deposited layer. For the cast steel roll, in terms of the hardness, thickness and quality of the deposited layer, the deposition power is 2000W, and the deposition voltage is 130V. The shielding gas flow rate of argon is set at 10L / min, and the elongation of the electrode is 3.5mm.

[0033] 2. The discharge frequency mainly affects the quality and deposition efficiency of the deposited layer, and the discharge frequency is selected to be 1400Hz.

[0034] 3. Within a certain period of time, the thickness of the deposited layer increases continuously with the prolongation of the deposition time during EDM deposition, but when it is deposited to a certain thickness, the thickness of the deposited layer not only does not increase with the increase of the deposition time, but also will become thinner, and the quality of the deposited layer will al...

Embodiment 2

[0040] Further illustrate the present invention below in conjunction with accompanying drawing.

[0041] The electrospark deposition processing equipment is used, and argon protection is introduced during the deposition process. The electrode adopts self-rotation mode (axial rotation), the electrode speed is 2400r / min, and the clamping mode of the electrode is mechanical. The parameters of EDM deposition are: output power 2400W; output voltage 120V; discharge frequency 2000HZ; deposition rate 3min / cm 2 , the shielding gas flow rate of argon is set at 7L / min, and the extension length of the electrode can be 3mm. When depositing, first clean the surface of the workpiece with gasoline or acetone to remove grease and scale.

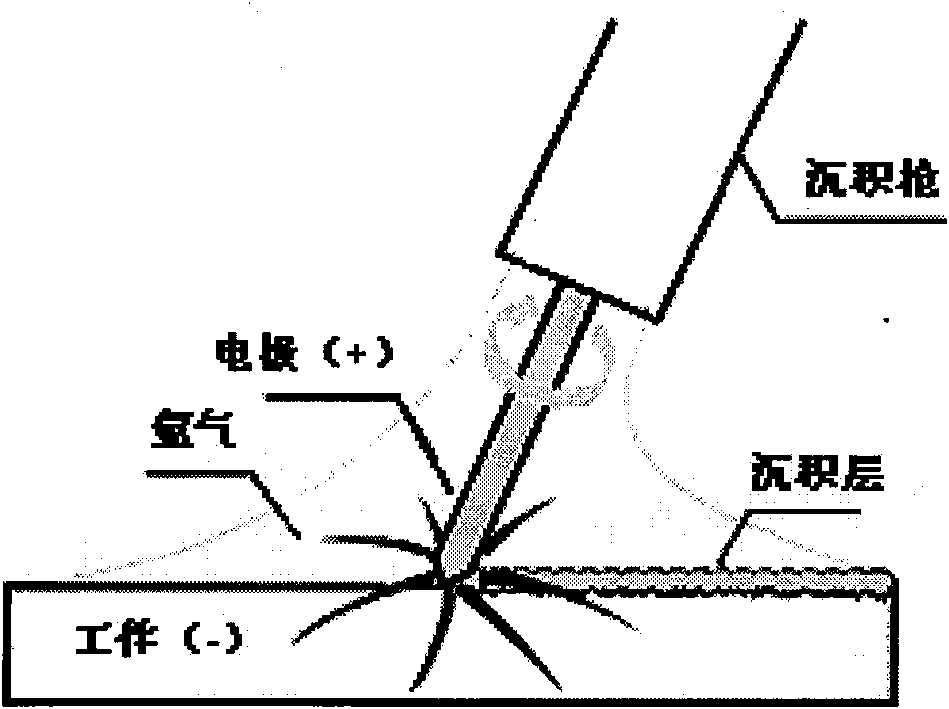

[0042] figure 1 The working principle diagram of the WC-Co electrode for the surface deposition treatment of the cast steel roll, which directly uses the high-density energy of electric energy to deposit the metal surface. The high-speed rotating electrode ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com