Environmental-protecting chemical gas-phase permeating technical method with stable running and device thereof

A chemical vapor infiltration and stable operation technology, applied in gaseous chemical plating, metal material coating process, coating, etc., can solve problems such as tar and carbon black substances are easy to block, pollute vacuum equipment, and poisonous substances pollute the environment. Achieve the effect of reducing clogged pipes and polluting vacuum equipment and ensuring stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

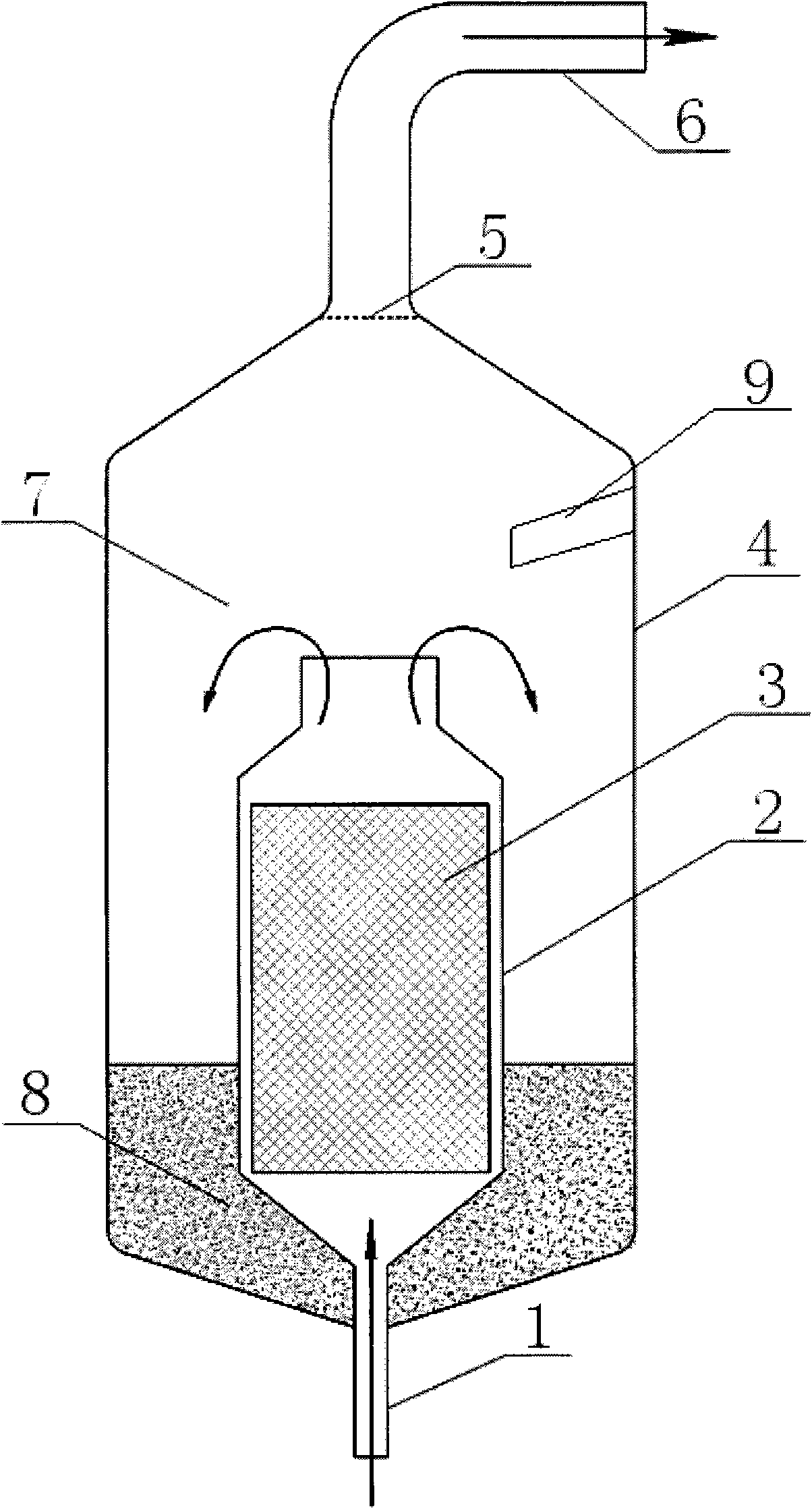

Embodiment 1

[0031] The carbon fiber prefabricated body is placed in a collective environment-friendly chemical vapor infiltration process equipment for densification treatment. The gap between the prefabricated body and the inner wall of the equipment is 5mm; hydrogen-diluted propane gas is used as the carbon source, and the gas flow rate is 50ml / s; The temperature in the densification zone of the preform is 1100°C±20°C, and the temperature in the tail gas thermal condensation polymerization-carbon black capture zone is 1200±20°C. During the 200-hour densification process, the total amount of carbon-containing pollutants discharged from the tail gas is only 15% of that of the conventional chemical vapor infiltration process, and the content of toxic substances in the tail gas is only 18% of that of the conventional chemical vapor phase infiltration process.

Embodiment 2

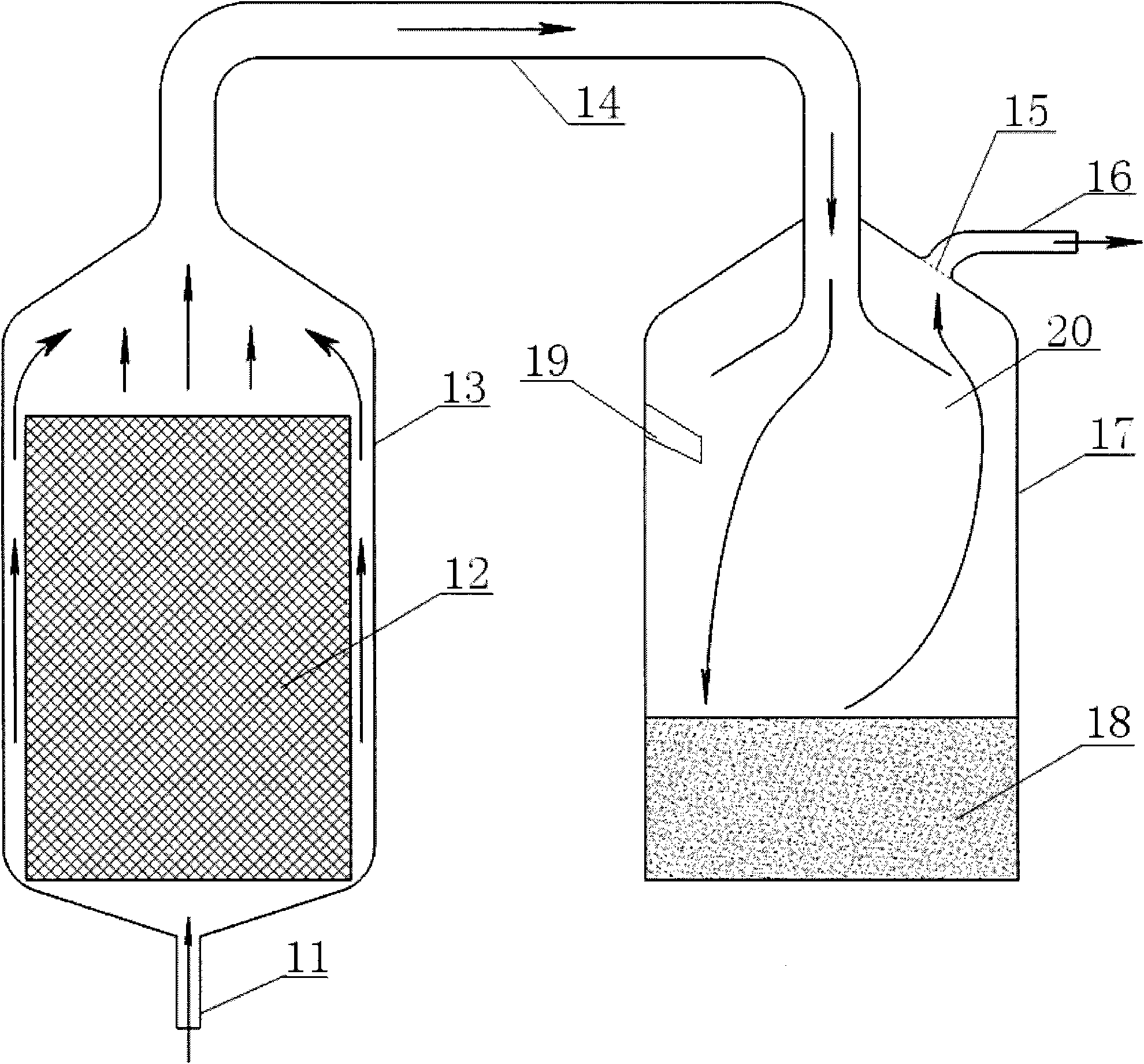

[0033] Put the carbon fiber prefabricated body in a discrete environment-friendly chemical vapor infiltration process equipment for densification treatment, the gap between the prefabricated body and the inner wall of the equipment is 8mm; hydrogen-diluted propane gas is used as the carbon source, and the gas flow rate is 100ml / s ; The temperature in the densification zone of the preform is 1100°C±20°C, the temperature of the tail gas transfer pipe is maintained at 600±100°C, and the temperature of the tail gas high-temperature pyrolysis furnace is 1200±20°C. During the 300-hour densification process, the total amount of carbon-containing pollutants discharged from the tail gas is only 12% of that of the conventional chemical vapor infiltration process, and the content of toxic substances in the tail gas is only 16% of that of the conventional chemical vapor phase infiltration process.

Embodiment 3

[0035]The carbon fiber prefabricated body is placed in a collective environment-friendly chemical vapor infiltration process equipment for densification treatment. The gap between the prefabricated body and the inner wall of the equipment is 5mm; hydrogen-diluted propane gas is used as the carbon source, and the gas flow rate is 50ml / s; The temperature in the densification zone of the preform is 1000°C±20°C, and the temperature in the tail gas thermal condensation polymerization-carbon black capture zone is 1100±20°C. Multiple batches of carbon fiber prefabricated bodies have been subjected to chemical vapor infiltration for a total of 10,000 hours. After inspection, there is no obvious pollution in the exhaust gas pipeline of the chemical vapor infiltration furnace and the vacuum pump equipment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com