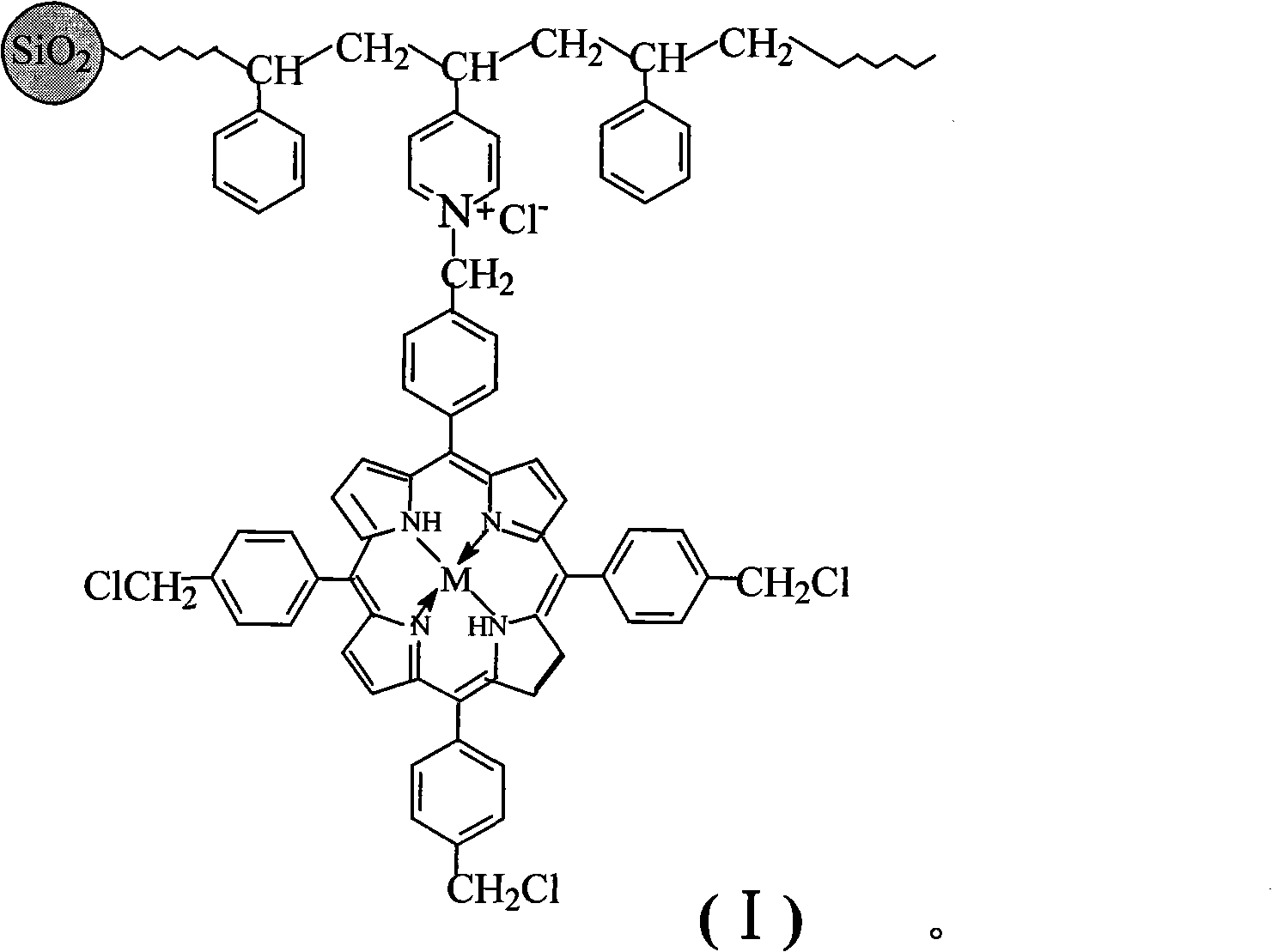

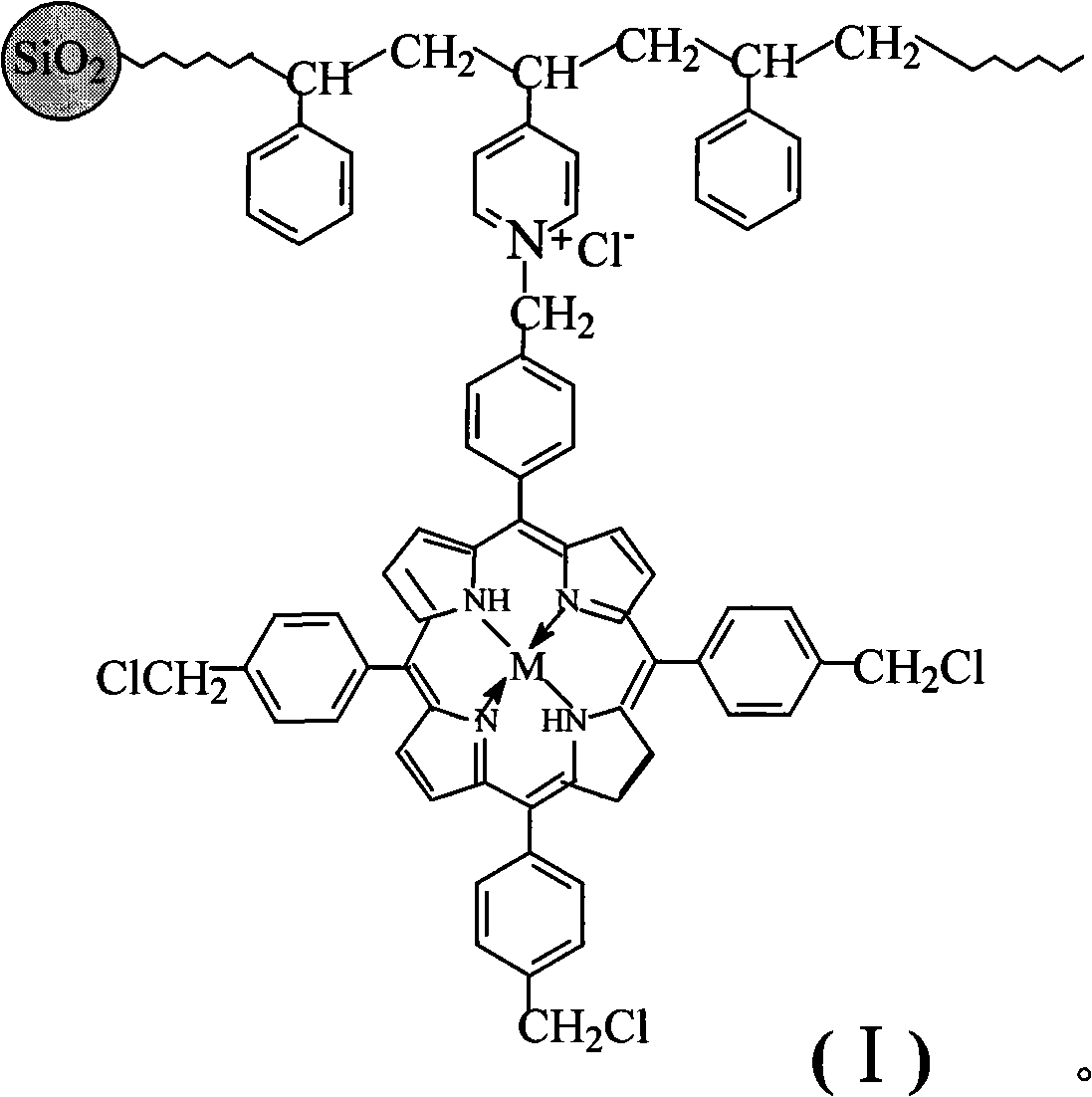

Preparation of silica gel supported metalloporphyrin compound and application method thereof

A metalloporphyrin, immobilized technology, applied in the preparation of organic compounds, the preparation of carbon-based compounds, catalyst activation/preparation, etc., can solve the problem that the catalyst cannot be reused, the catalytic performance lacks stability, and the yield of acetophenone Low problems, to achieve the effect of promoting catalytic performance, less catalyst dosage, and improving yield and selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1: Weigh 2.0000 g of the silica gel-immobilized porphyrin prepared in any of the above Examples 1, Example 2, and Example 3, soak in 45ml DMF, add 0.40g cobalt chloride, and react at 130°C for 1.5h, and reduce pressure A certain amount of solvent was recovered by distillation, the reaction solution was filtered while it was hot, washed with DMF, water, ethanol in turn, and dried to obtain 2.0159g of silica gel-supported metalloporphyrin, the metallization degree was 99.8%, and the solid load of cobalt porphyrin was 0.0903 g / g.

Embodiment 2

[0022] Example 2: Weigh 2.0000g of the silica gel immobilized porphyrin prepared in any of the above Examples 1, Example 2, and Example 3, soak in 40ml DMF, add 0.29g ferric chloride, react at 120°C for 2h, and distill under reduced pressure A certain amount of solvent is recovered, the reaction solution is filtered while it is hot, washed with DMF, water, ethanol, and dried to obtain 2.0151g of silica gel-supported metalloporphyrin, the degree of metallization is 99.5%, and the solid load of iron porphyrin is 0.0898g / g.

Embodiment 3

[0023]Example 3: Weigh 2.0000 g of the silica gel-immobilized porphyrin prepared in any of the above Examples 1, Example 2, and Example 3, soak in 50ml DMF, add 0.15g manganese chloride, and react at 110°C for 2.5 hours. A certain amount of solvent was recovered by distillation, the reaction solution was filtered while it was hot, washed with DMF, water, ethanol in turn, and dried to obtain 2.0134g of silica gel-supported metalloporphyrin, with a metallization degree of 99.0% and a solid loading of manganese porphyrin of 0.0811 g / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com