Solid borne ionic liquid Cu salt catalyst as well as preparation method thereof and application in synthesis of dimethyl carbonate

A technology of ionic liquid and catalyst, which is applied in the field of immobilized ionic liquid Cu salt catalyst and its preparation, can solve problems such as no reports, and achieve the effects of reducing equipment corrosion, avoiding large dosage, and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

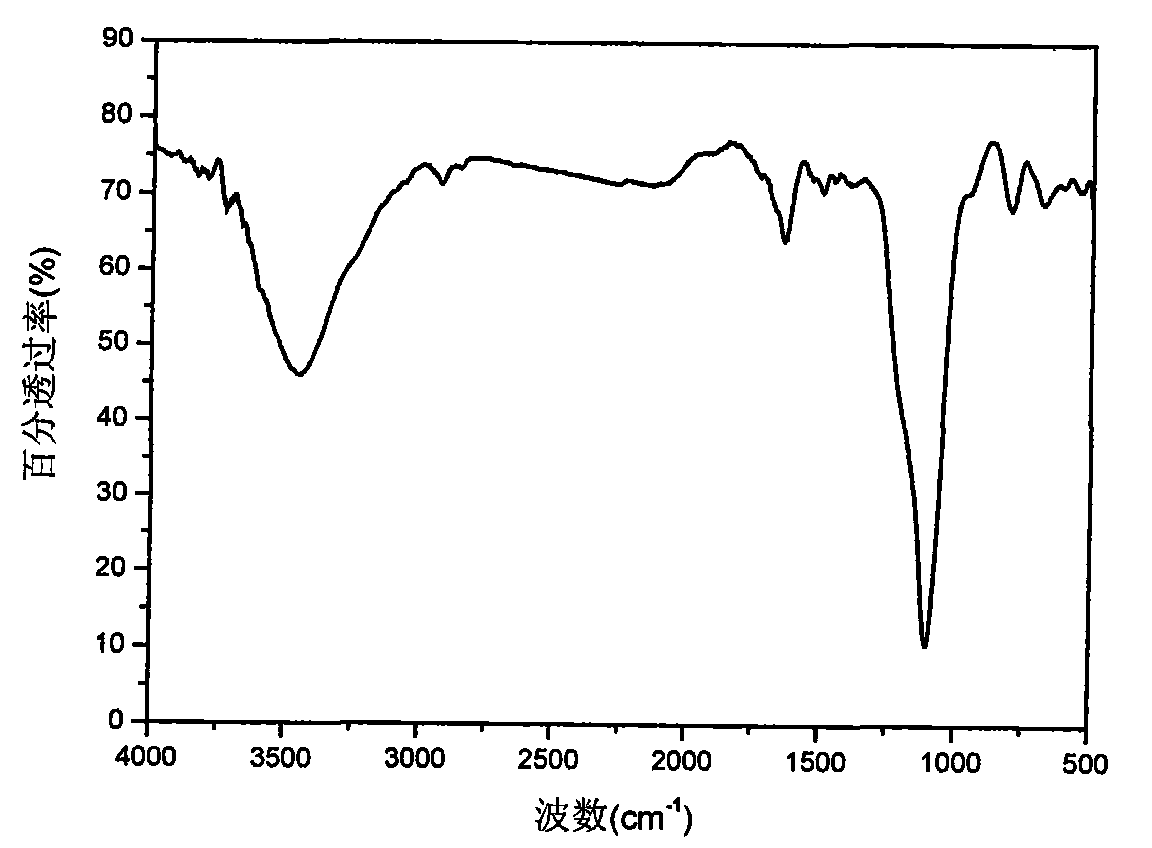

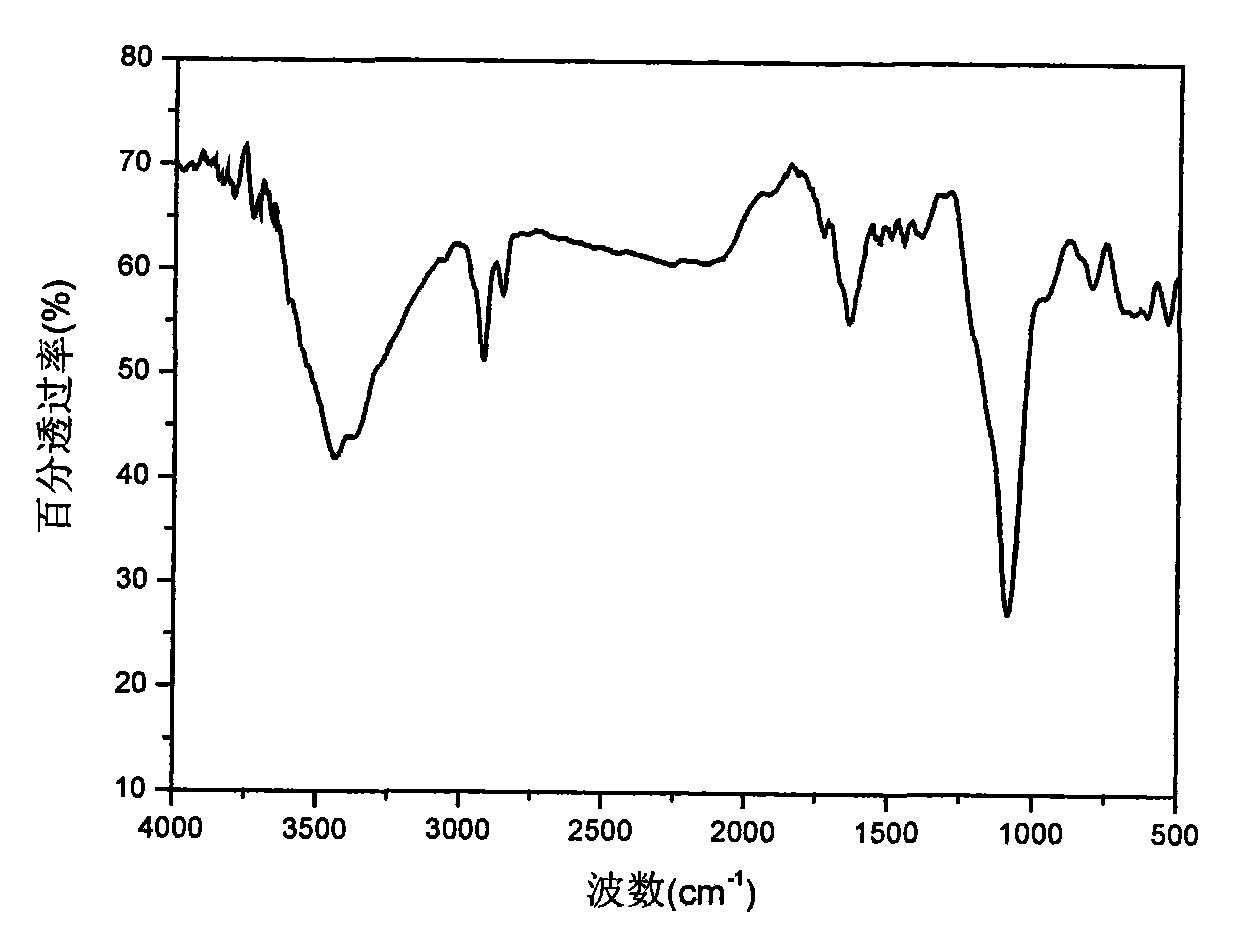

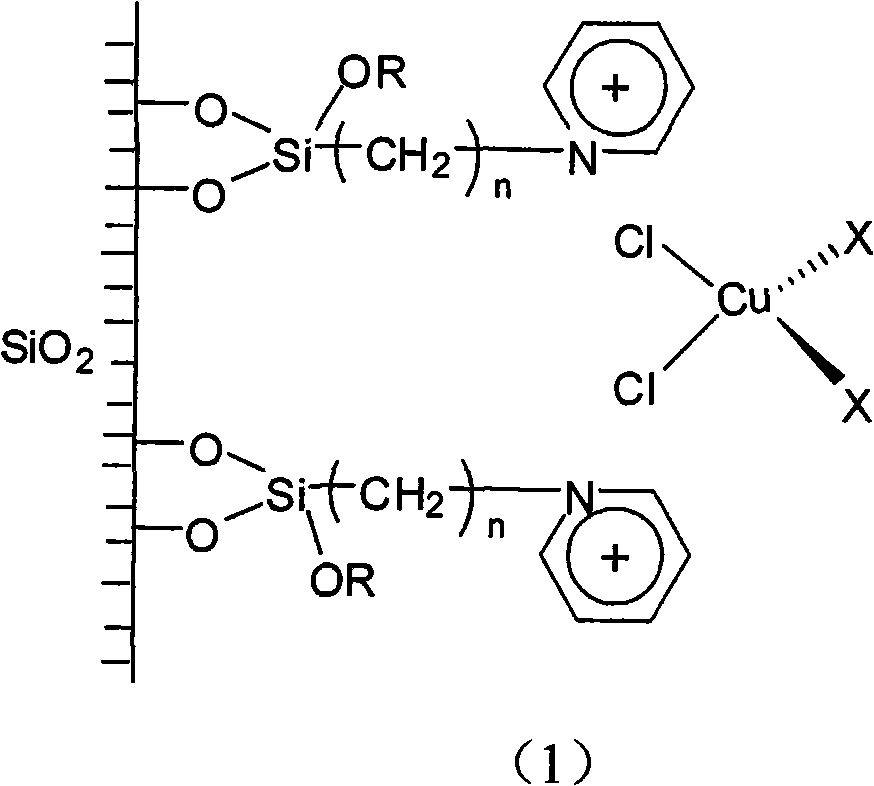

[0028] In the immobilized ionic liquid Cu salt catalyst represented by structural formula (1), the carrier is B-type silica gel, n is 3, and R is CH 3 , X is Br. The preparation method of the immobilized ionic liquid Cu salt catalyst of this structural formula is as follows:

[0029] 1. Preparation of pyridine ionic liquid

[0030]Add 59.62g of 3-chloropropyltrimethoxysilane and 47.46g of pyridine into a three-necked flask, the molar ratio of 3-chloropropyltrimethoxysilane to pyridine is 1:2, react at 95°C for 24 hours in an Ar atmosphere, Stand still, extract three times with 1,1,1-trichloroethane, and evaporate in a rotary evaporator to prepare trimethoxysilylpropylpyridinium chloride ionic liquid.

[0031] 2. Preparation of Immobilized Ionic Liquid Matrix

[0032] Add 6g of B-type silica gel and 3g of trimethoxysilyl propylpyridinium chloride ionic liquid into a three-necked flask, then add 54g of acetonitrile, in an Ar atmosphere, react at 70°C for 24 hours, filter with...

Embodiment 2

[0036] In the immobilized ionic liquid Cu salt catalyst represented by structural formula (1), the carrier is B-type silica gel, n is 3, and R is CH 3 , X is Br. The preparation method of the immobilized ionic liquid Cu salt catalyst of this structural formula is as follows:

[0037] In step 1 of the preparation method of the present invention, 19.87g of 3-chloropropyltrimethoxysilane and 7.91g of pyridine were added to a three-necked flask, and the molar ratio of 3-chloropropyltrimethoxysilane to pyridine was 1:1. React at 80°C for 48 hours in an Ar atmosphere, let stand, extract 3 times with 1,1,1-trichloroethane, evaporate in a rotary evaporator, and prepare trimethoxysilylpropylpyridinium chloride ionic liquid . In step 2 of the preparation method of the present invention, 6 g of B-type silica gel and 1.8 g of trimethoxysilylpropylpyridinium chloride ionic liquid were added to a three-necked flask, and then 32.4 g of acetonitrile were added, and reacted at 60 ° C for 20 ...

Embodiment 3

[0039] In the immobilized ionic liquid Cu salt catalyst represented by structural formula (1), the carrier is B-type silica gel, n is 3, and R is CH 3 , X is Br. The preparation method of the immobilized ionic liquid Cu salt catalyst of this structural formula is as follows:

[0040] In step 1 of the preparation method of the present invention, 19.87g of 3-chloropropyltrimethoxysilane and 23.73g of pyridine were added to a three-necked flask, and the molar ratio of 3-chloropropyltrimethoxysilane to pyridine was 1:3. React at 110°C for 20 hours in an Ar atmosphere, let stand, extract three times with 1,1,1-trichloroethane, evaporate in a rotary evaporator, and prepare trimethoxysilylpropylpyridinium chloride ionic liquid. In step 2 of the preparation method of the present invention, 3 g of B-type silica gel and 3 g of trimethoxysilylpropylpyridinium chloride ionic liquid were added to a three-necked flask, and then 54 g of acetonitrile was added, and reacted at 80° C. for 16 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com