Method for separating nano-particles at water-phase density gradient centrifugation rate

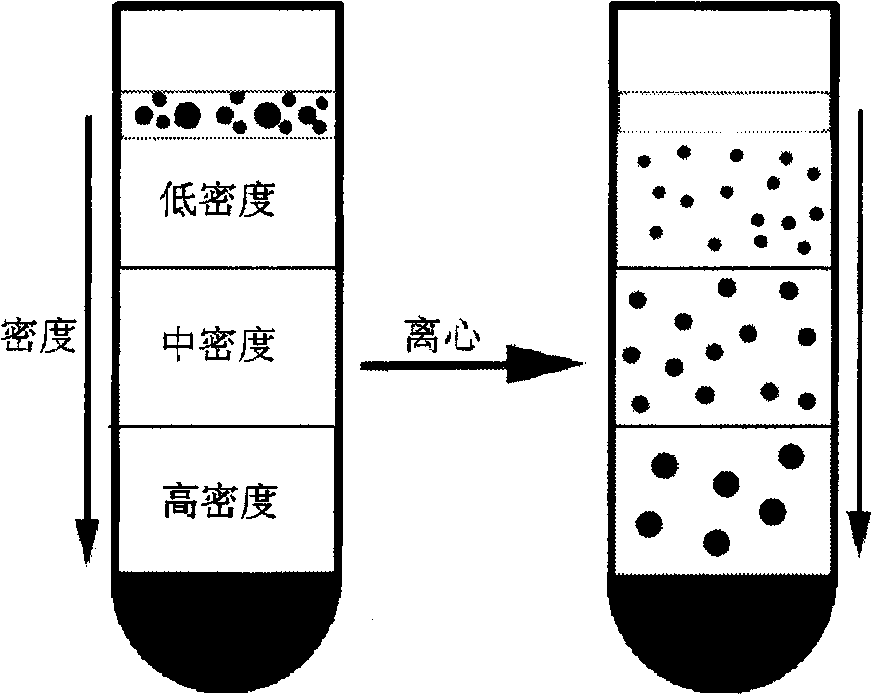

A nanoparticle and gradient centrifugation technology, which is applied in solid separation, wet separation, chemical instruments and methods, etc. The effect of wide size range, good separation effect and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] (1) First, 0.1 mg of Au nanoparticle suspension containing 5nm, 10nm and 20nm was added to mercapto-polyethylene glycol 5000 aqueous solution, ultrasonically dispersed, and then concentrated to reduce its volume to 0.2ml.

[0046](2) Make a density gradient: dilute with 60% iodixanol (density 1.32 g / ml) solution by mass percentage to prepare 30%, 40%, and 50% iodixanol solutions respectively. Take 0.75ml each to prepare a density gradient solution of 30%+40%+50%+60%.

[0047] (3) Slowly add 0.2 ml of mixed Au colloidal nanoparticle solution onto the density gradient solution.

[0048] (4) High-speed centrifugation at 15°C, 50,000 rpm, and 15 minutes.

[0049] (5) Take out the centrifuged colloidal nano-dispersion from the top in equal volumes in batches (100ul / time, marked as fn in turn). Finally, Au nanoparticles with different sizes were obtained.

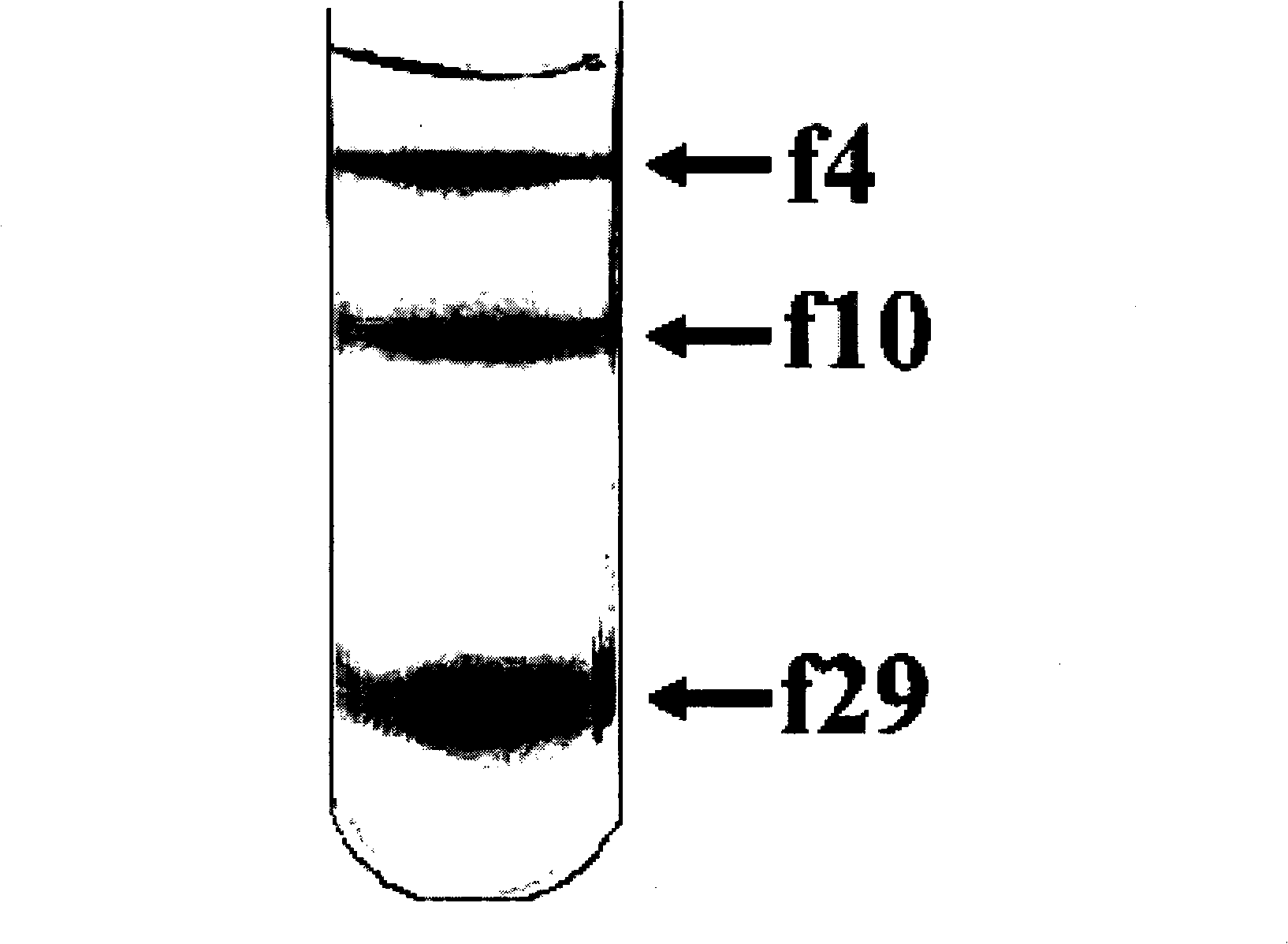

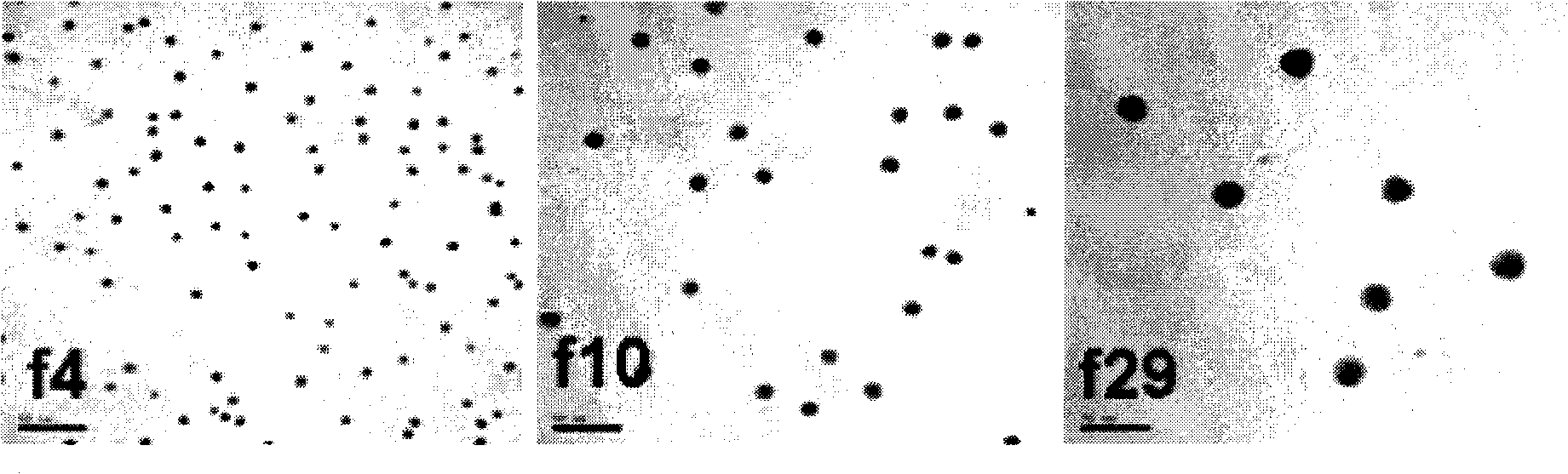

[0050] For separation results, see figure 2 , 3. Similar effects can be achieved by using sucrose, albumin, glycer...

Embodiment 2

[0052] (1) First, about 0.5 mg of 4 nm FeCo@C nanoparticles were ultrasonically dispersed in 5 ml of phospholipid-methylpolyethylene glycol 5000 surfactant solution with a concentration of 1 mg / ml to form 0.1 mg / ml FeCo@C colloids Nanoparticle solution.

[0053] (2) Make density gradient: dilute with 60% iodixanol (density 1.32g / ml) solution by mass percentage to prepare 10%, 20%, 30%, 40% iodixanol solutions respectively. Take 0.75ml each to prepare a density gradient solution of 10%+20%+30%+40%.

[0054] (3) Slowly add 0.2ml FeCo@C colloidal nanoparticle solution to the density gradient solution.

[0055] (4) High-speed centrifugation at 10°C, 45,000 rpm, and 210 minutes.

[0056] (5) Take out the centrifuged colloidal nano-dispersion from the top in equal volumes in batches (100ul / time, marked as fn in turn). Finally, FeCo@C nanoparticles with different sizes were obtained.

[0057] For separation results, see Figure 4 . Similar effects can be achieved by using album...

Embodiment 3

[0059] (1) First, graphite oxide is ultrasonicated in water to prepare a solution of about 2 mg / ml graphene oxide colloidal nanoparticles.

[0060] (2) Make a density gradient: first make a sucrose solution with a mass percentage of 70% (density of 1.34g / ml), then dilute the 70% sucrose solution to prepare 20%, 30%, 40%, 50%, 60% % sucrose solution. Take 0.5ml each to prepare a density gradient solution of 20%+30%+40%+50%+60%+70%.

[0061] (3) Slowly add 0.2ml graphene oxide colloidal nanoparticle solution to the density gradient solution.

[0062] (4) High-speed centrifugation at 15°C, 50,000 rpm, and 15 minutes.

[0063] (5) Take out the centrifuged colloidal nano-dispersion from the top in equal volumes in batches (100ul / time, marked as fn in turn). Finally, graphene oxide with different sizes is obtained.

[0064] For separation results, see Figure 5 . Similar effects can be achieved by using albumin, glycerol, sorbitol, meglumine, and iodixanol solutions with the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com