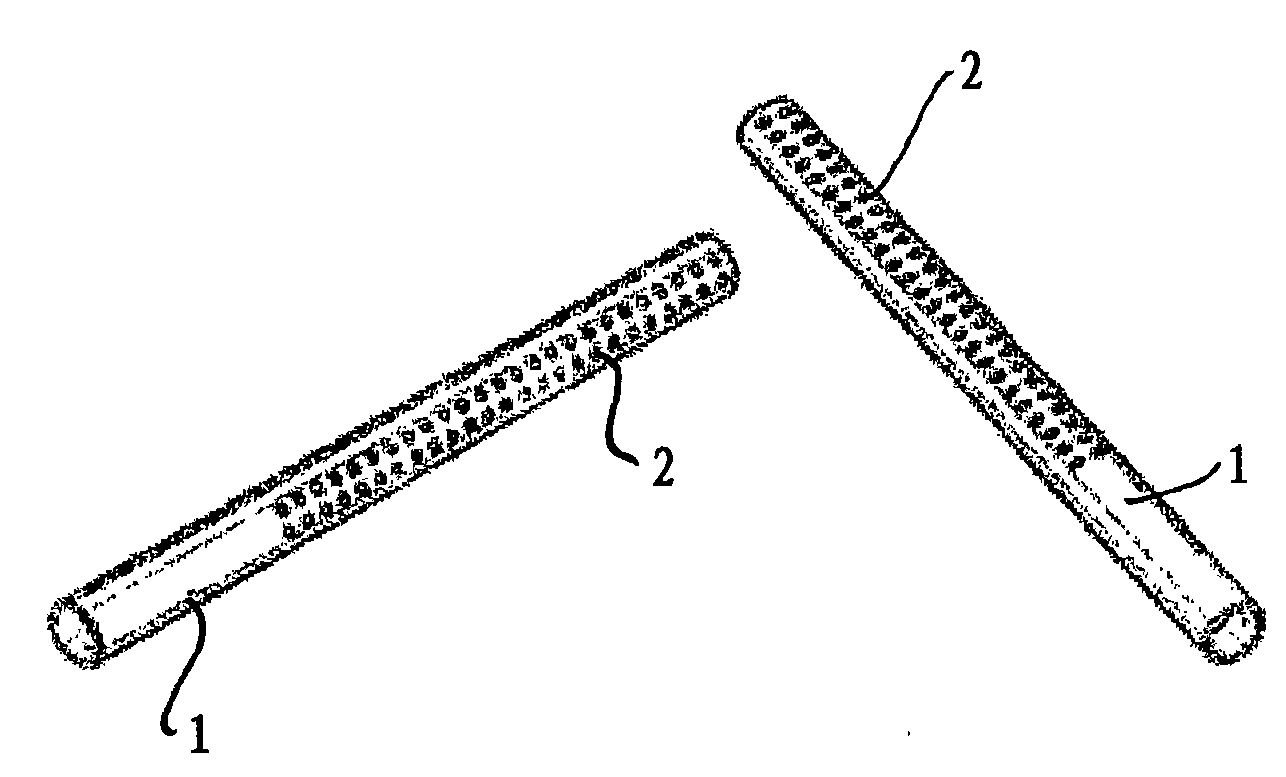

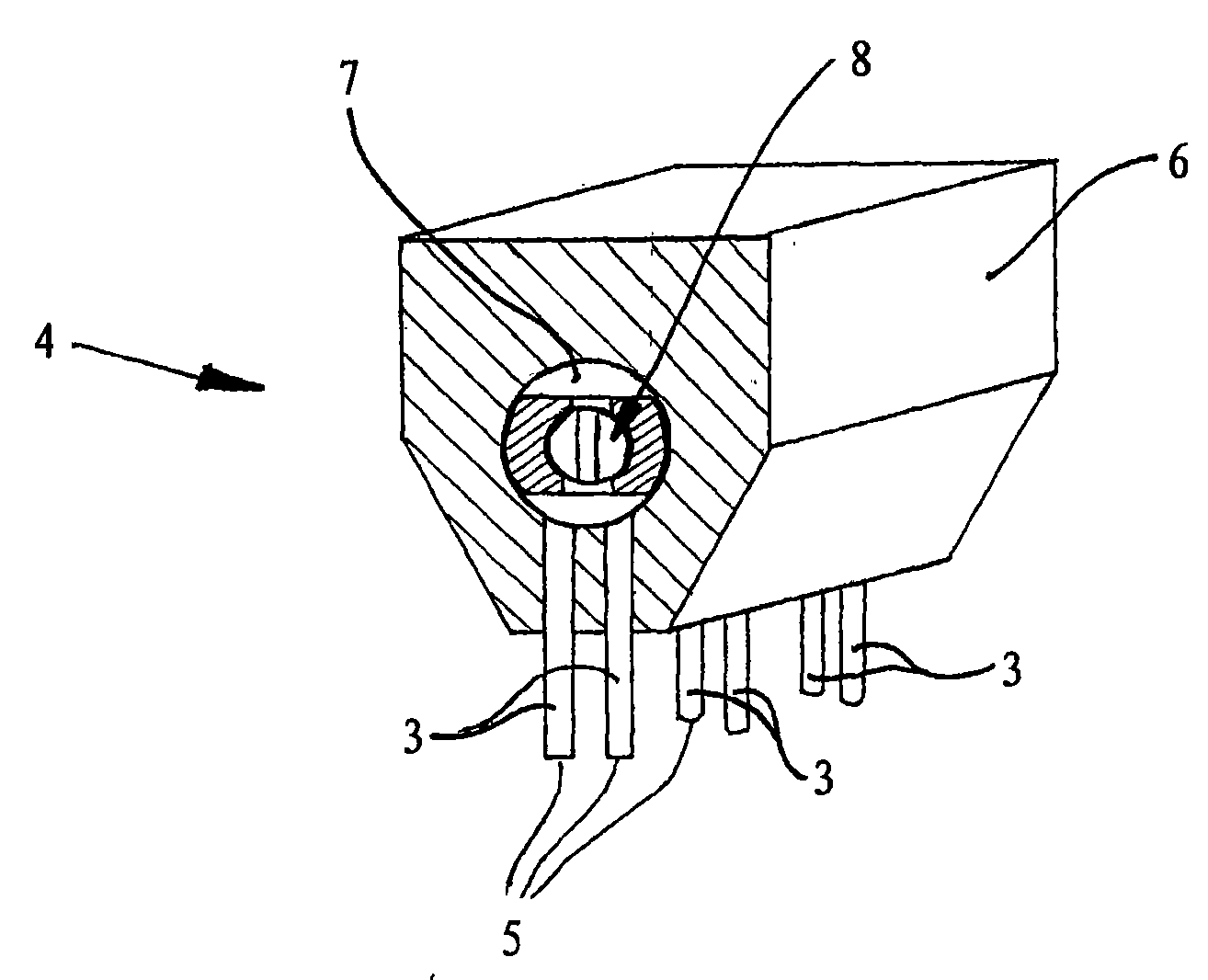

Method for producing raised structures on surface of pencil

A technology of plastics and preparations, which is applied in the field of producing raised structures on the surface of pens, which can solve the problems of nozzle wire parts pollution, untidy appearance, irregularities, etc., and achieve the effect of eliminating the increase in the viscosity of preparations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

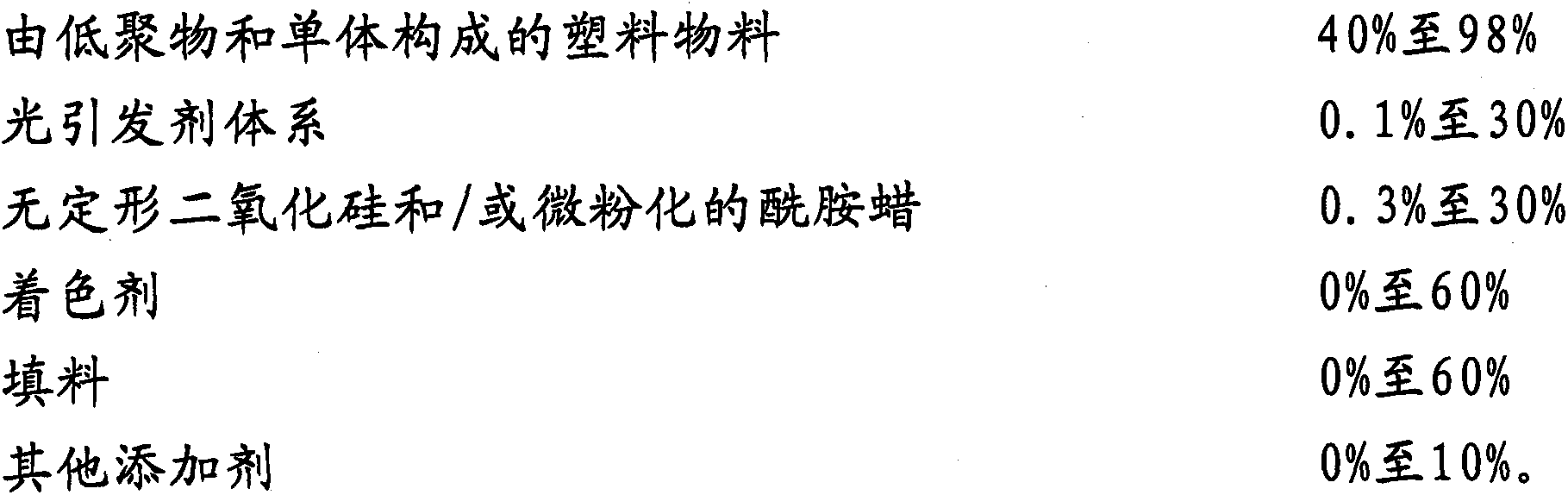

[0026] UV-crosslinkable plastic formulation for transparent or colorless gripping nubs with a diameter of 2 mm and a height of 0.5 mm for plastic rods.

[0027] raw material

Features

A

B

C

Roskydal UA VP LS

2258 (Bayer Material

Science)

Aliphatic Urethane-Propylene

esters, oligomers

77.3%

57.3%

57.3%

Roskydal UA XP 2491

(Bayer Material

Science)

Aliphatic Urethane-Propylene

esters, oligomers

20%

20%

20%

Laromer TPGDA (BASF)

Tripropylene glycol triacrylate,

-

20%

18%

Irgacure 2959 (Ciba)

Alpha-Hydroxyketone, Photoinitiator

2%

2%

2%

HDK T30 (Wacker

Chemie AG)

-

-

2%

Tego Glide 440

(Evonik)

surfactants, leveling agents and

0.5%

...

Embodiment 2

[0038] UV-crosslinkable plastic formulation for black-dyed grasping nubs with dimensions as in Example 1.

[0039] raw material

Features

D

E

F

G

H

I

Roskydal UA VP LS 2258

(Bayer Material

Science)

aliphatic carbamate

ester acrylate,

75.8%

54.8%

54.8%

54.8%

73.8%

52.8%

Roskydal UA XP 2491

(Bayer Material

Science)

aliphatic carbamate

ester acrylate,

20%

20%

20%

20%

20%

20%

Laromer TPGDA (BASF)

Tripropylene Glycol Tripropylene

Acrylic esters, reactive

-

20%

18%

18%

-

20%

Irgacure 2959 (Ciba)

Alpha-Hydroxyketone, Light

Initiator

2%

2%

2%

2%

2%

2%

Irgac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com