Method for directly preparing graphene/cadmium sulfide quantum dot nano composite material with one step by adopting graphite oxide as material

A nanocomposite material and graphene technology, applied in the direction of nanotechnology, nanotechnology, nanostructure manufacturing, etc., can solve the problems of low content of single-layer graphene, difficulty in preparation, high cost of preparation of graphene functional materials, etc., and achieve energy conversion efficiency The effect of high and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

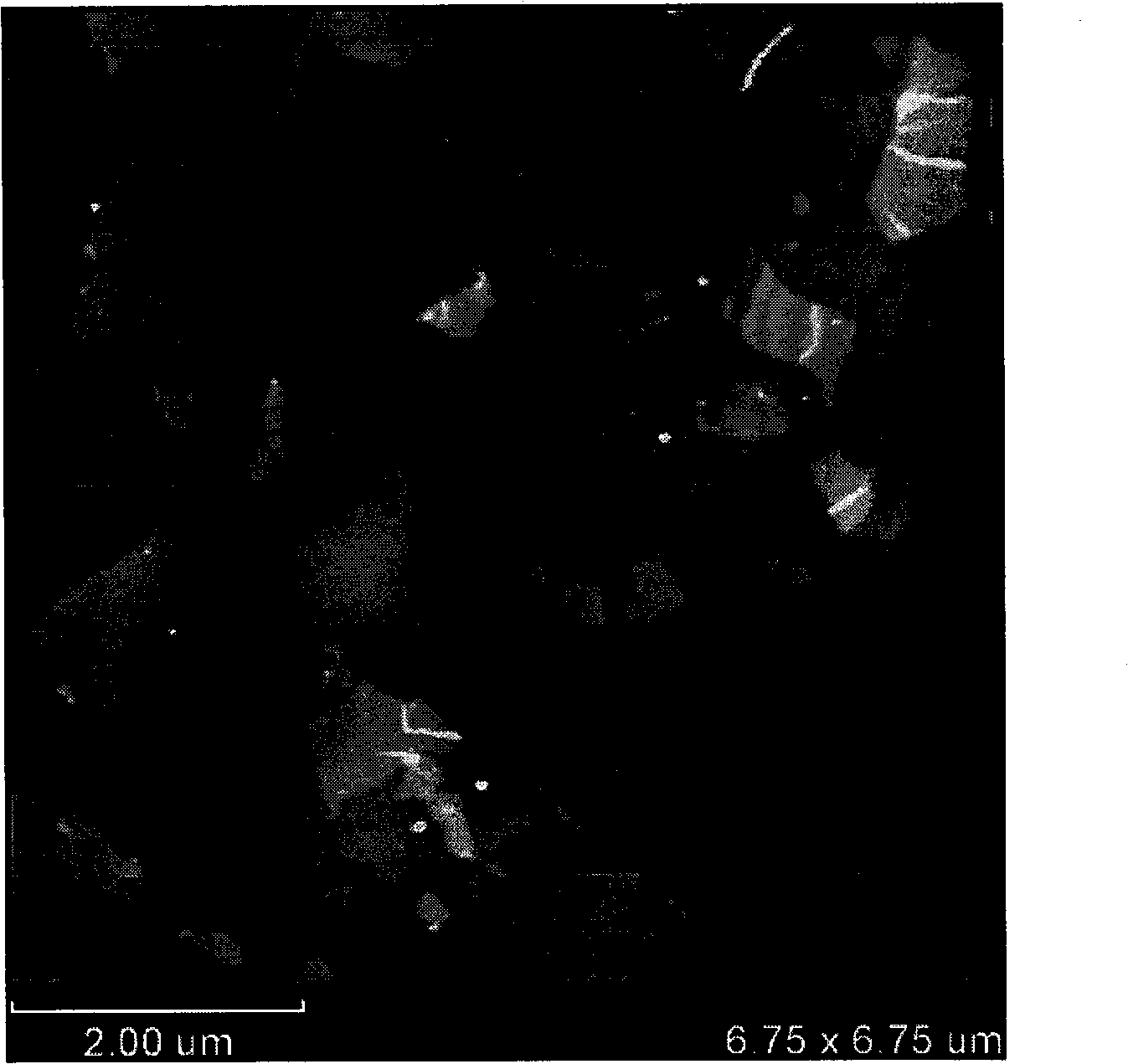

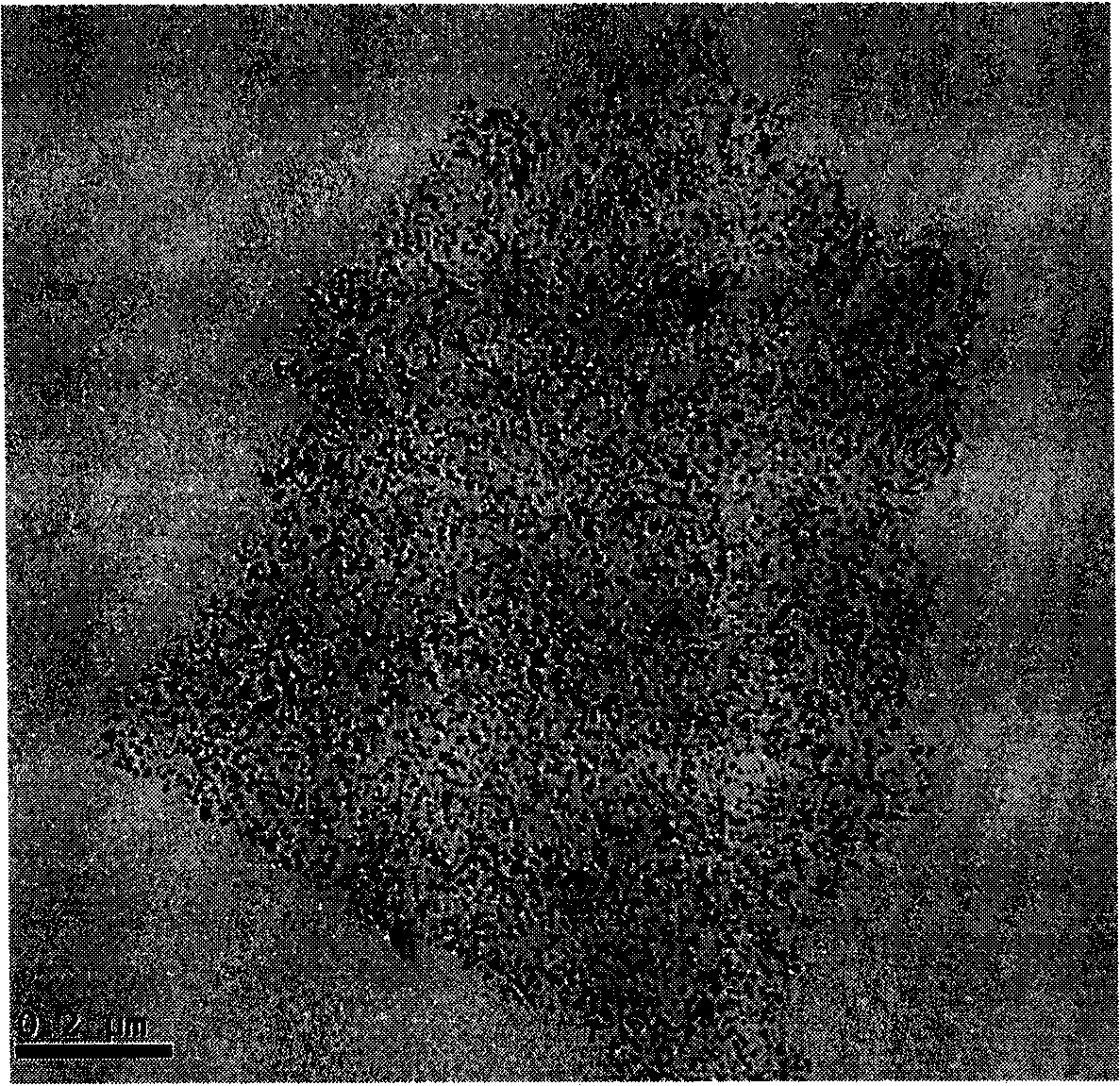

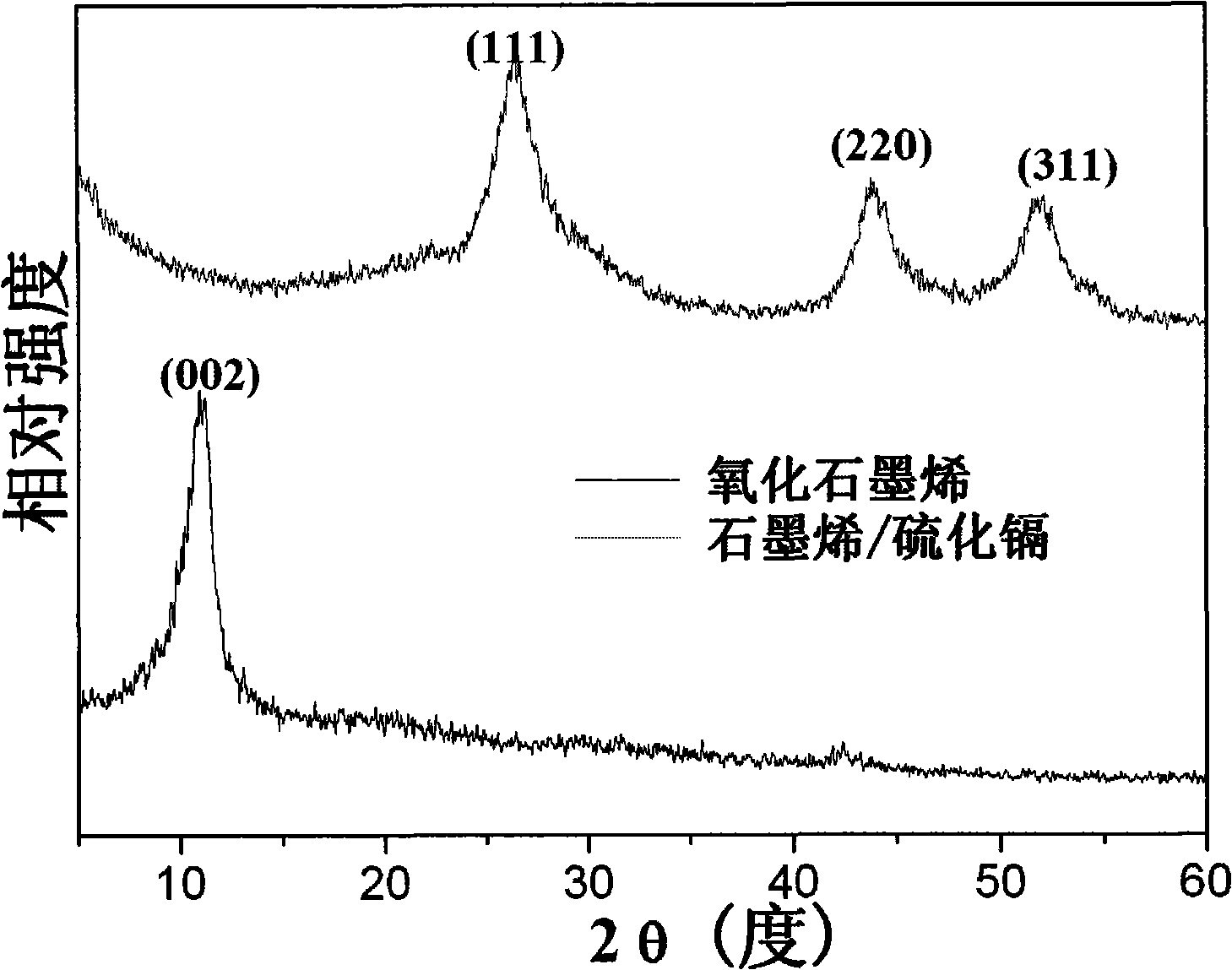

[0016] The preparation process and steps in this embodiment are as follows:

[0017] 1. Preparation of graphite oxide and graphene oxide solution: use natural graphite powder as raw material, get 3 grams of natural graphite powder with a fineness of 325 meshes, add 12 milliliters of concentrated sulfuric acid, 2.5 grams of potassium persulfate and 2.5 grams of phosphorus pentoxide , mixed evenly at 80°C, and allowed to react for 4.5 hours; the mixture was cooled to room temperature, diluted with deionized water and allowed to stand overnight, then separated by filtration with a cellulose acetate membrane with 0.2 micron pores, and washed with a large amount of deionized water , the product was left standing overnight at room temperature; the above product, namely pre-oxidized graphite, was stirred and slowly added to a mixed solution of 120 ml of cooled concentrated sulfuric acid at 0°C and 15 grams of potassium permanganate, and stirred at 35°C After 2 hours, dilute with 250 ...

Embodiment 2

[0020] The preparation process and steps in this example are exactly the same as those in Example 1 above. The difference is: the annealing temperature in the high-temperature reactor is 150° C., and the annealing time is 8 hours, and finally the composite material is obtained.

Embodiment 3

[0022] The preparation process and steps in this example are exactly the same as those in Example 1 above. The difference is: the annealing temperature in the high-temperature reactor is 200° C., and the annealing time is 16 hours, and finally the composite material is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com