Method for preparing nanoscale mesoporous silica spheres

A mesoporous silica, nano-scale technology, applied in the preparation of mesoporous silica spheres, particle size control and preparation of nano-scale mesoporous silica spheres, can solve the problem of long synthesis time and synthesis process Complicated, non-adjustable particle size and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

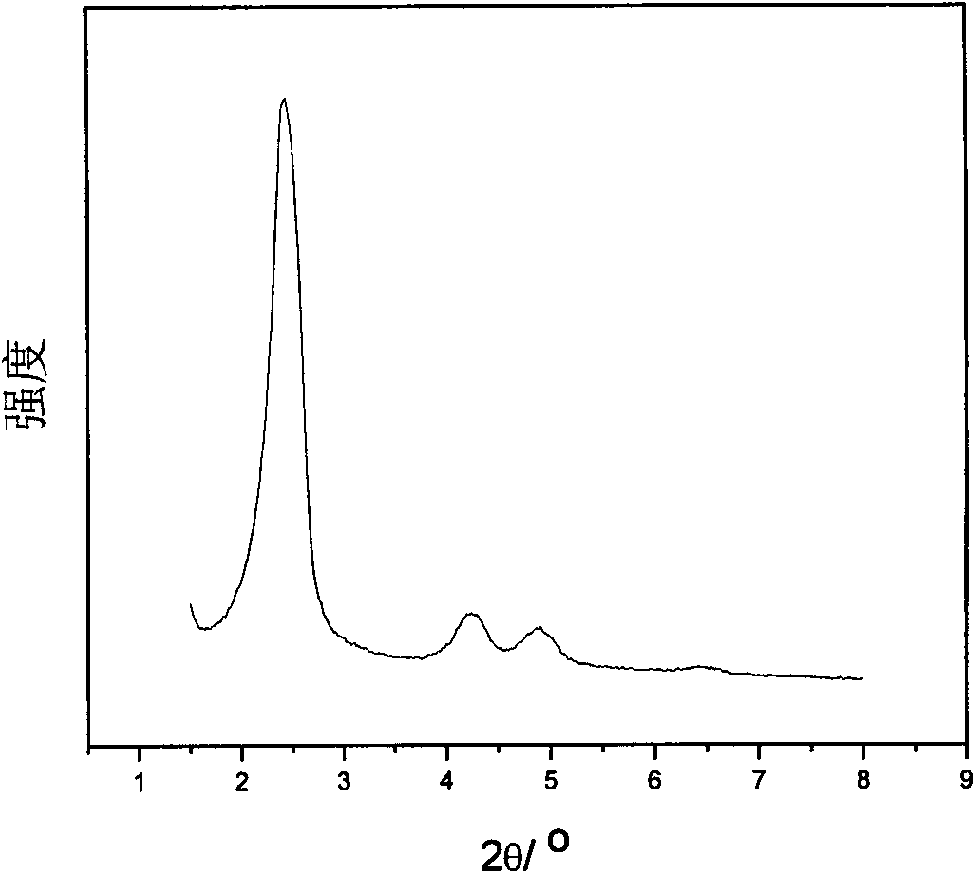

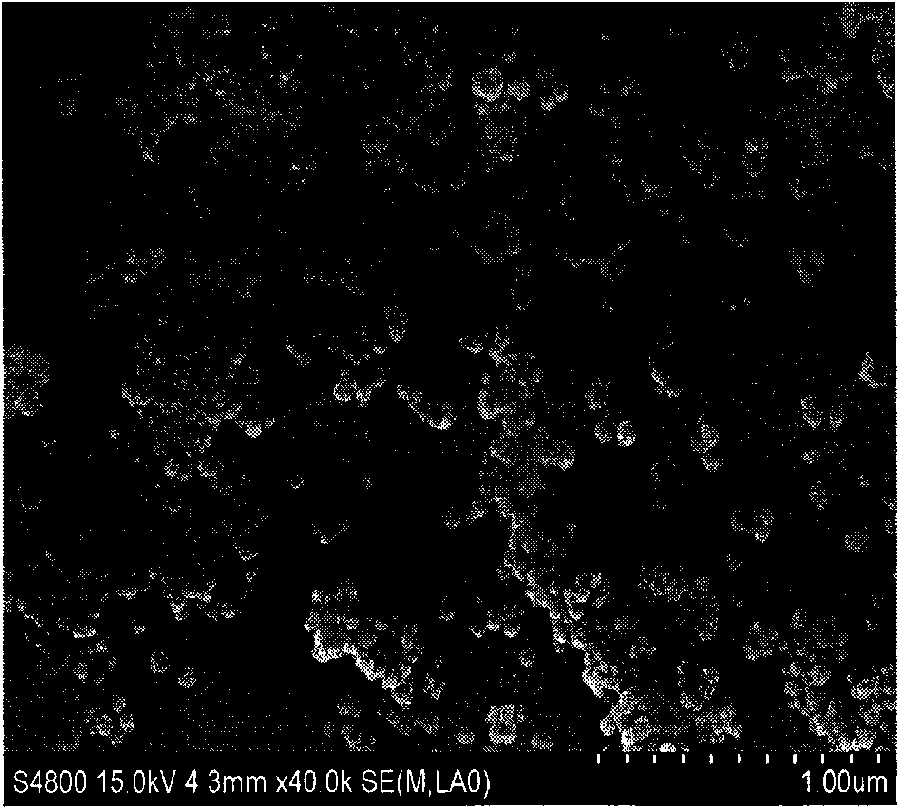

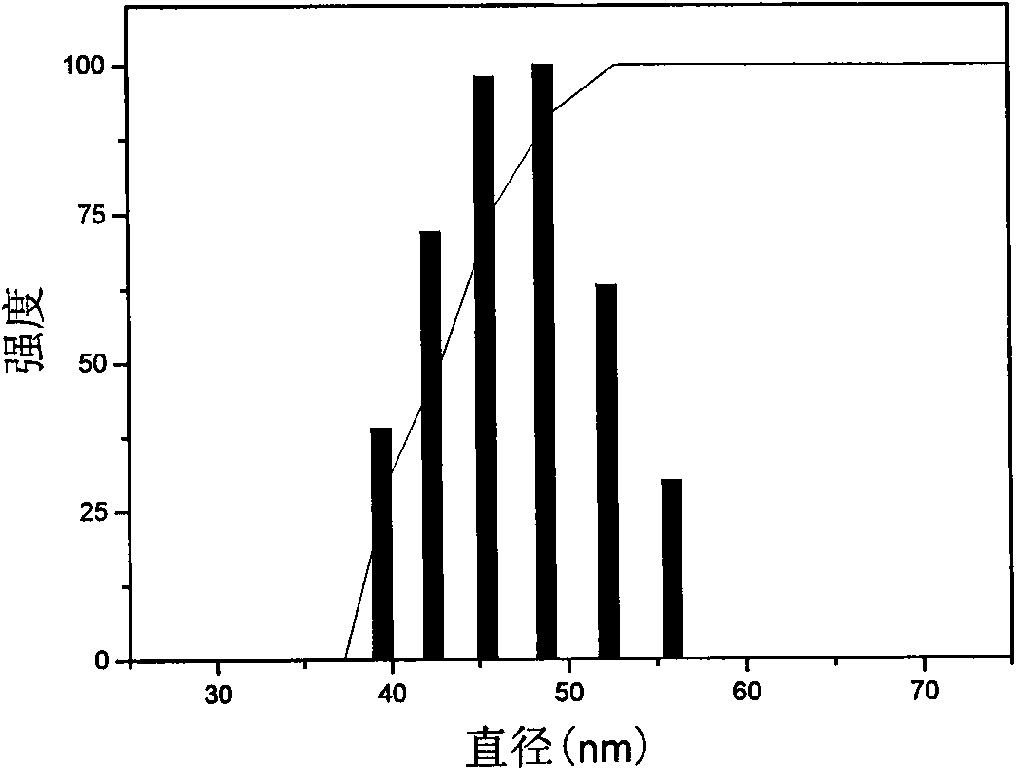

[0022] Dissolve 1.0g cetyltrimethylammonium bromide (CTAB) in 192ml deionized water, stir until clear, add 1.0ml 1mol / L NaOH solution dropwise, stir the above solution at 80°C, add 5.68ml Tetraethyl orthosilicate was kept under the above conditions and stirred for 2 hours to obtain a reaction solution containing a white precipitate. Then the mixed solution was filtered and dried at room temperature to obtain a white solid powder. The powder was put into a muffle furnace at 550° C. and roasted for 1 hour with nitrogen gas, and then with air for 4 hours to obtain the medium after the template agent was burned. Porous silica, analyzed and tested by XRD, HRSEM, BET, HRTEM, particle size distribution, etc., shows that its microscopic shape is spherical, the average particle size is 49nm, the particle size distribution range is 40-55nm, and the specific surface is 803m 2 / g, the pore size is 2.2nm, its XRD, FE-SEM, HRTEM and particle size distribution are as follows Figure 1-a , 1-...

example 2

[0024] Operate with embodiment 1, only change the amount of NaOH, drop the NaOH solution of 2.0ml 1mol / L, the average particle diameter of the sample obtained by reaction is 180nm, specific surface is 747m 2 / g, the pore size is 2.6nm.

example 3

[0026] The ratio of the reactants and the reaction conditions are the same as in Example 2, the template agent is changed to octaalkyltrimethylammonium bromide, the average particle diameter of the sample obtained from the reaction is 380nm, and the specific surface is: 971m 2 / g, the pore size is 1.9nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Specific surface | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com