Preparation method of nano-diamond friction coat by laser coating

A nano-diamond and laser cladding technology, which is applied in the coating process and coating of metal materials, can solve the problems of poor matrix bonding performance, loose organization, particle shedding, etc., to achieve uniform composition, reduce crack sensitivity, Effect of avoiding loss of diamond material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Add 20% nano-diamond powder to the iron-based alloy powder, put the mixed powder into alcohol, and use a digital ultrasonic generator to generate 28 / 40KHz frequency ultrasound for ultrasonic vibration and mixing for 10 minutes; then evaporate the alcohol, and pass through Ball mill to mix. The workpiece to be clad is placed in the vacuum chamber first, and the mixed powder obtained in the previous step is preset on the surface of the workpiece to be clad by a gravity powder feeder, and the solid YAG pulsed laser is introduced into the vacuum chamber through an optical fiber for cladding. The cladding power is 400W, the pulse frequency is 10Hz, the pulse width is 3ms, and the vacuum degree is greater than 1×10 -3 Pa. The thickness of the obtained cladding layer reaches 1.5 mm, and the mass loss is 62% of that of GCr15 when it is rubbed against GCr15.

Embodiment 2

[0023] Add 10% nano-diamond powder to the Ni35 alloy powder, put the mixed powder into alcohol, and use a digital ultrasonic generator to generate 28 / 40KHz frequency ultrasound for ultrasonic vibration and mixing for 10 minutes; then evaporate the alcohol. Put the workpiece to be clad into the vacuum chamber first, pre-set the mixed powder obtained in the previous step on the surface of the workpiece to be clad by pre-spreading powder, and guide the solid YAG pulse laser into the vacuum chamber through the optical fiber for cladding. Laser cladding The power is 300W, the pulse frequency is 30Hz, the pulse width is 8ms, and the vacuum degree is greater than 1×10 -3 pa. The thickness of the obtained cladding layer is about 1 mm, and the mass loss is 56.3% of that of GCr15 when it is rubbed against GCr15.

Embodiment 3

[0025] Add 5% nano-diamond powder to the GH30 alloy powder, put the mixed powder into alcohol, and use a digital ultrasonic generator to generate 28 / 40KHz frequency ultrasound for ultrasonic vibration and mixing for 10 minutes; then evaporate the alcohol. Put the workpiece to be clad into the vacuum chamber first, pre-set the mixed powder obtained in the previous step on the surface of the workpiece to be clad by pre-spreading powder, and guide the solid YAG pulse laser into the vacuum chamber through the optical fiber for cladding. Laser cladding The power is 150W, the pulse frequency is 20Hz, the pulse width is 5ms, and the vacuum degree is greater than 1×10 -3 pa. The thickness of the obtained cladding layer is about 0.5mm, and the mass loss is 62% of the matrix when it is rubbed against the GH30 matrix.

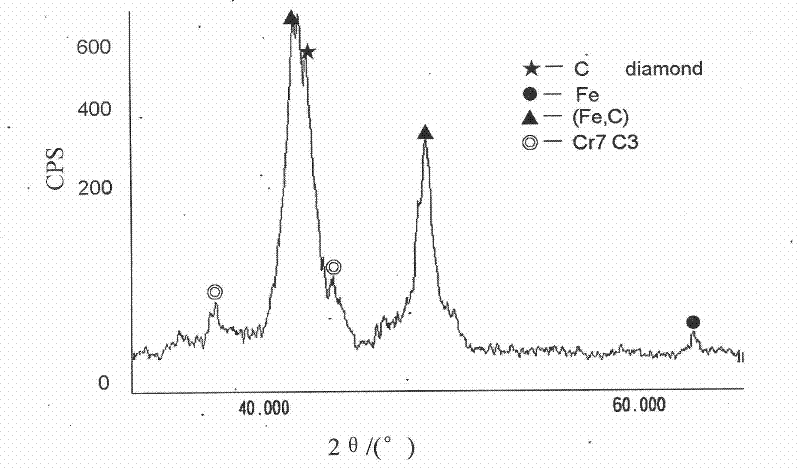

[0026] figure 1 It is the diamond phase diagram in the nano-diamond antifriction coating prepared in embodiment 1, and the magnification is 2×10 4 times from figure 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com