Lithium-sulfur battery and preparation method thereof

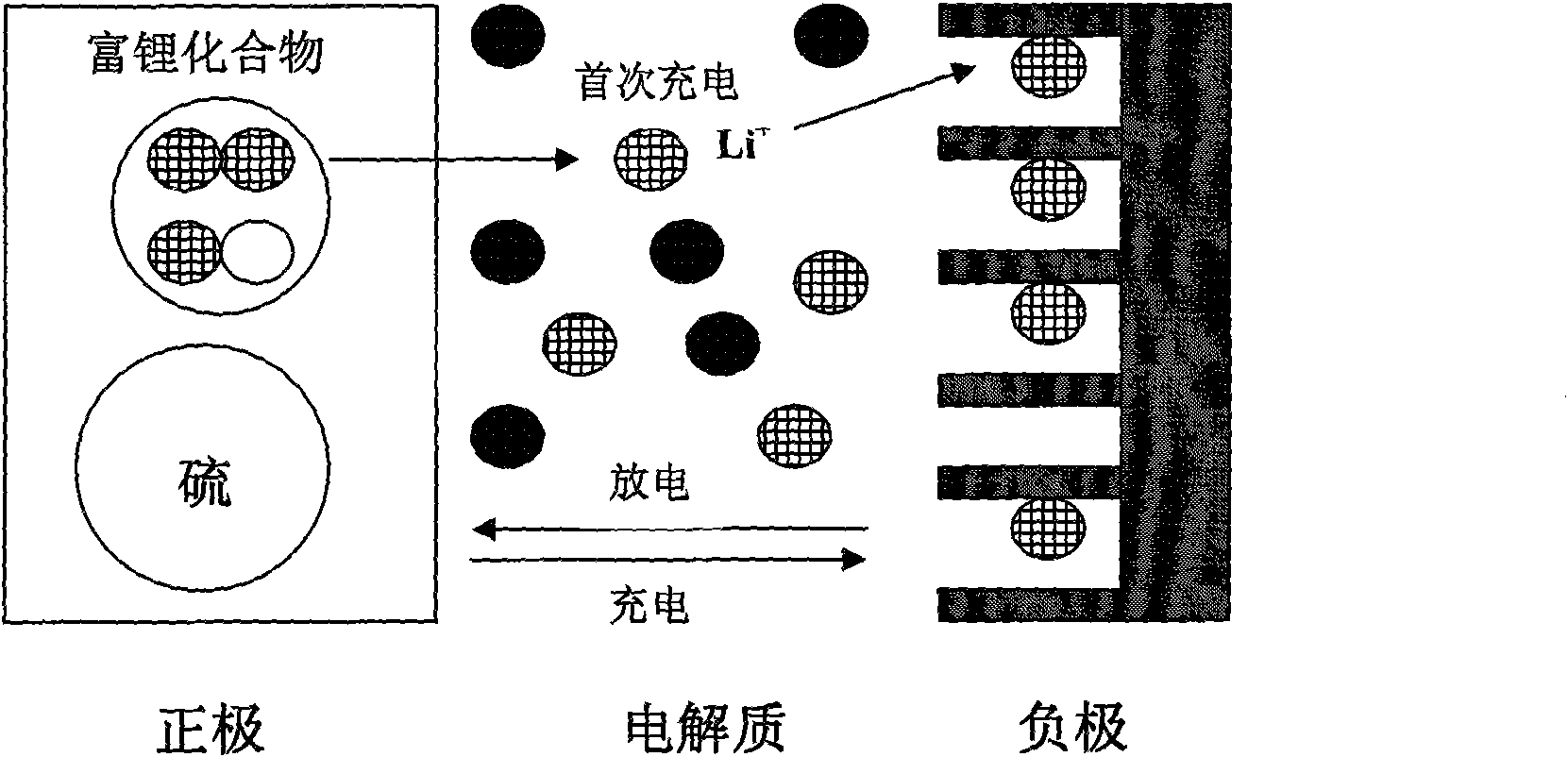

A lithium-sulfur battery, lithium-rich technology, applied in the field of electrochemical batteries, can solve the problems of electrolyte solution decomposition and capacity decline, unstable protective layer, cracking, etc., to achieve good application prospects, cycle performance and safety performance improvement, cost low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

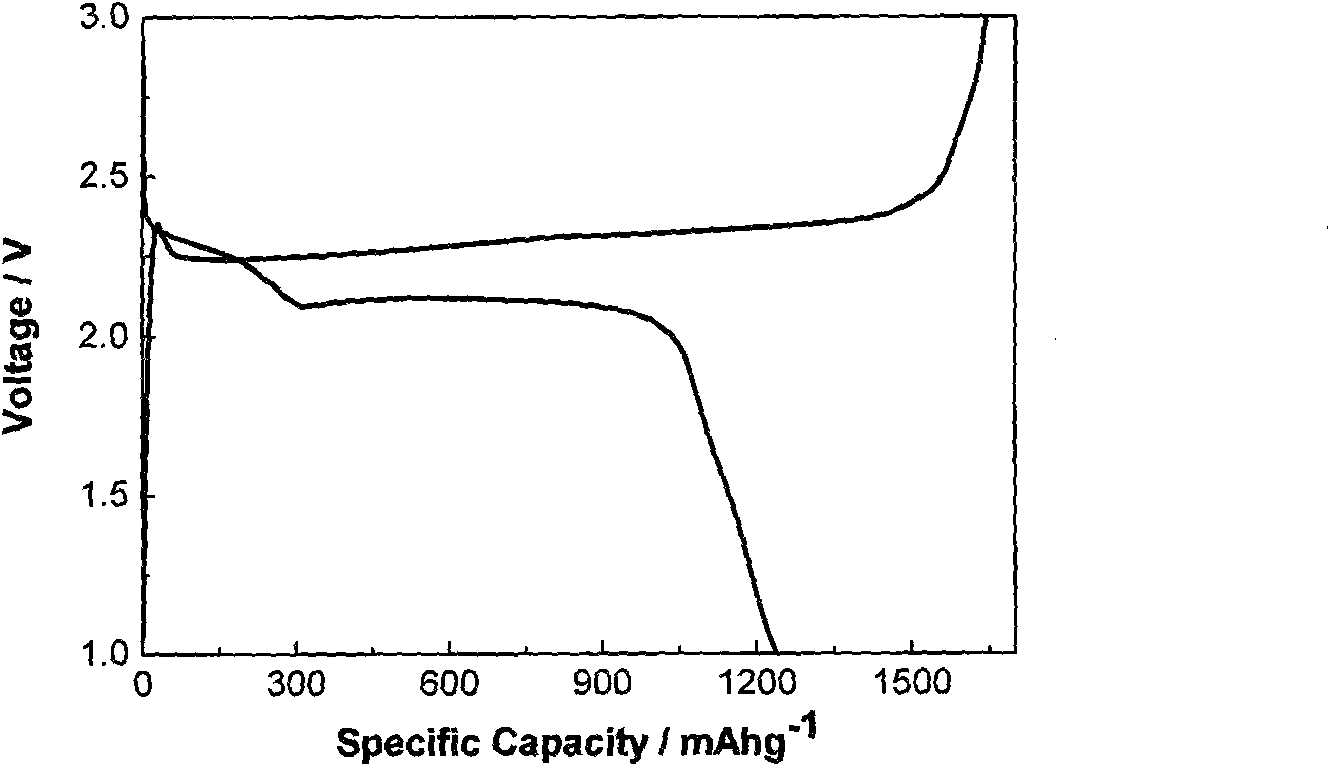

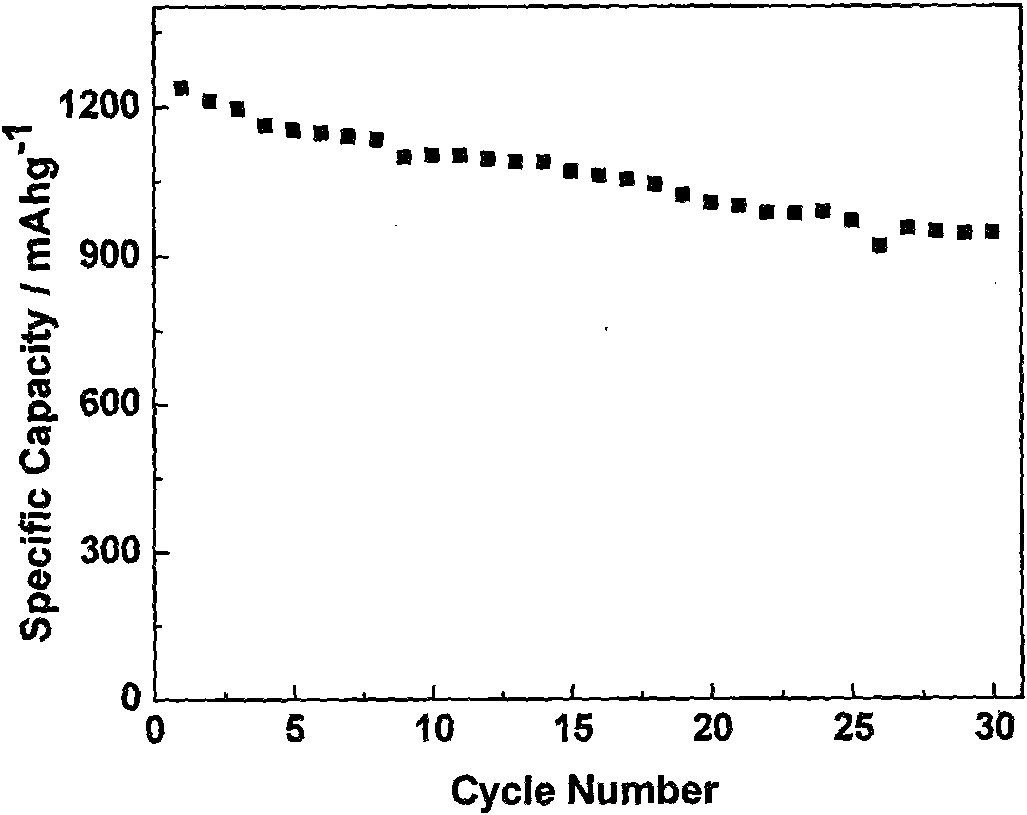

[0020] With sublimed sulfur as the positive electrode, doped with 10% LiNi 0.5 co 0.5 o 2 , the mixture was mixed uniformly with acetylene black and polyvinylidene fluoride (PVDF) in a mass ratio of 80:10:10, and N-methyl-2-pyrrolidone (NMP) was used as a solvent, and ball milled at a speed of 200 rpm for 4 h in a stainless steel ball mill tank , the obtained paste slurry was uniformly coated on the current collector Al foil, and then dried in a vacuum oven at 60°C for 20 hours for use. Graphite is used as the negative electrode material, mixed evenly with acetylene black and polyvinylidene fluoride (PVDF) at a mass ratio of 85:10:5, and N-methyl-2-pyrrolidone (NMP) is used as the solvent, and the temperature is 200 rpm in a stainless steel ball mill tank. The speed of ball milling was 2 hours, and the obtained paste slurry was evenly coated on the current collector Cu foil, and then dried in a vacuum oven at 60°C for 20 hours for use. The sulfur electrode is used as the po...

Embodiment 2

[0023] Using carbyne polysulfide as the positive electrode, doped with 40% LiNi 0.5 co 0.5 o 2 , the mixture was mixed with acetylene black and polyethylene oxide (PEO) in a mass ratio of 80:10:10, and deionized water was used as a solvent, and ball milled for 4 hours at a speed of 200 rpm in a stainless steel ball mill tank, and the obtained paste slurry was evenly coated Cloth it on the current collector Al foil, and then dry it in a vacuum oven at 60°C for 20 hours for later use. Mesocarbon microspheres (MCMB) were used as the negative electrode material, mixed with acetylene black and polyvinylidene fluoride (PVDF) at a mass ratio of 85:10:5, and N-methyl-2-pyrrolidone (NMP) was used as the solvent. Ball milled at a speed of 200 rpm for 2 h in a stainless steel ball mill jar, and the obtained paste slurry was uniformly coated on the Cu foil of the current collector, and then dried in a vacuum oven at 60° C. for 20 hours for use. A lithium-sulfur battery was assembled wi...

Embodiment 3

[0026] With sublimed sulfur as the positive electrode, doped with 10% Li by mass 2.6 co 0.4 N, mix the mixture with acetylene black and polyvinylidene fluoride (PVDF) in a mass ratio of 80:10:10, use N-methyl-2-pyrrolidone (NMP) as solvent, and ball mill at a speed of 200rpm in a stainless steel ball mill tank 4h, the obtained paste slurry was uniformly coated on the current collector Al foil, and then dried in a vacuum oven at 60°C for 20 hours for later use. Hard carbon is used as the negative electrode material, mixed evenly with acetylene black and polyvinylidene fluoride (PVDF) in a mass ratio of 85:10:5, and N-methyl-2-pyrrolidone (NMP) is used as the solvent. Ball mill at a speed of 200rpm for 2h, and the obtained paste slurry is evenly coated on the Cu foil of the current collector, and then dried in a vacuum oven at 60°C for 20 hours for use. With the sulfur electrode as the positive electrode, the hard carbon electrode as the negative electrode, Celgrad2300 as the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com