Sludge steel slag ultra light ceramsite and method for preparing same

A technology of ultra-light pottery and steel slag, applied in the field of environmental science, to achieve the effects of sustainable economic development, low water absorption, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) After the dewatered sludge is dried, the steel slag and clay are dried, the three raw materials are crushed, and sieved with a 100-mesh sieve (particle diameter ≤ 0.15mm);

[0033] (2) Weighing 10wt%, 80wt%, and 10wt% of the dried and pulverized sludge, clay, and converter steel slag, and mixing them evenly, adding an appropriate amount of water and stirring until it is sticky, and then making raw meal balls by conventional methods;

[0034] (3) Dry the raw meal balls at room temperature for 15 hours;

[0035] (4) Put the raw material balls into a 350°C box-type resistance furnace, preheat for 20 minutes; quickly transfer to a 1100°C tube-type resistance furnace and bake for 8 minutes; naturally cool to room temperature to obtain ultra-light ceramsite.

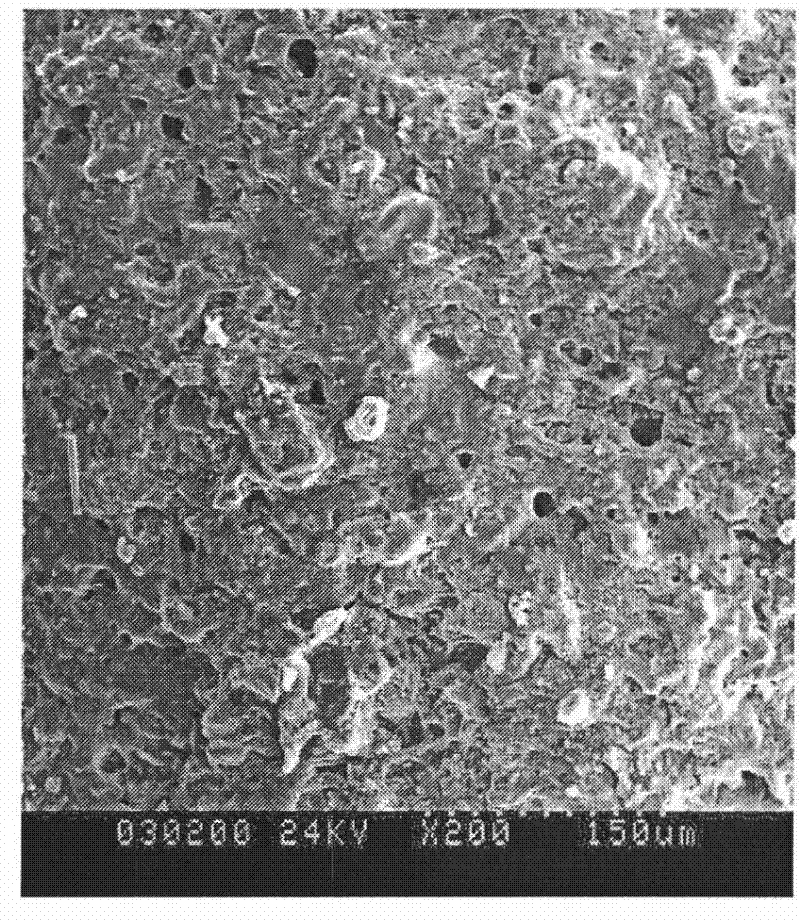

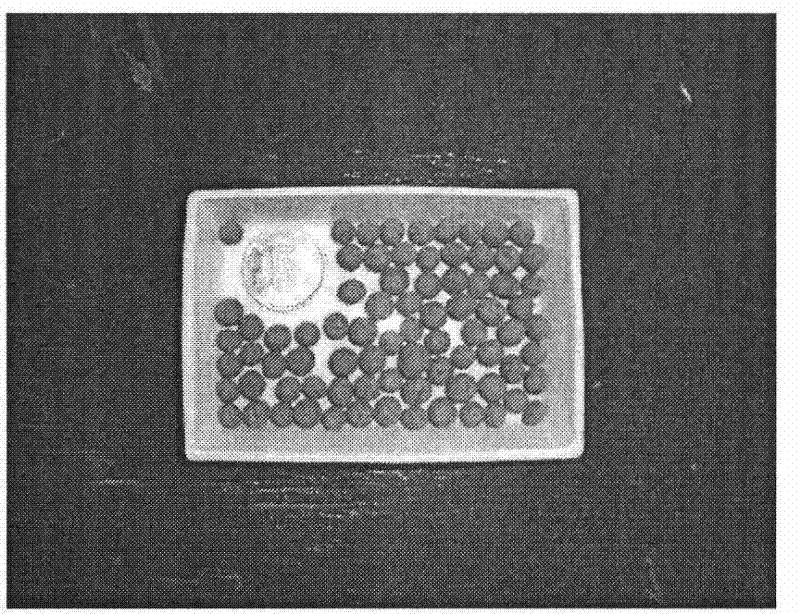

[0036] The appearance of the prepared ultra-light ceramsite is dark brown or bright black spherical solid with rough surface, and the bulk density is 421kg / m 3 , the particle density is 760kg / m 3 , can float in wa...

Embodiment 2

[0040] (1) the processing of three kinds of raw materials is with embodiment 1;

[0041] (2) Weigh and mix 20wt% of dried and pulverized sludge, 65wt% of clay and 15wt% of converter steel slag, stir evenly, then add water and stir until viscous, and make raw meal balls by conventional methods;

[0042] (3) Place the raw meal balls at room temperature and dry for 10 hours;

[0043] (4) Put the raw material balls into a 370°C box-type resistance furnace, preheat for 15 minutes; quickly transfer to a 1080°C tube-type resistance furnace and bake for 10 minutes; naturally cool to room temperature to obtain ultra-light ceramsite.

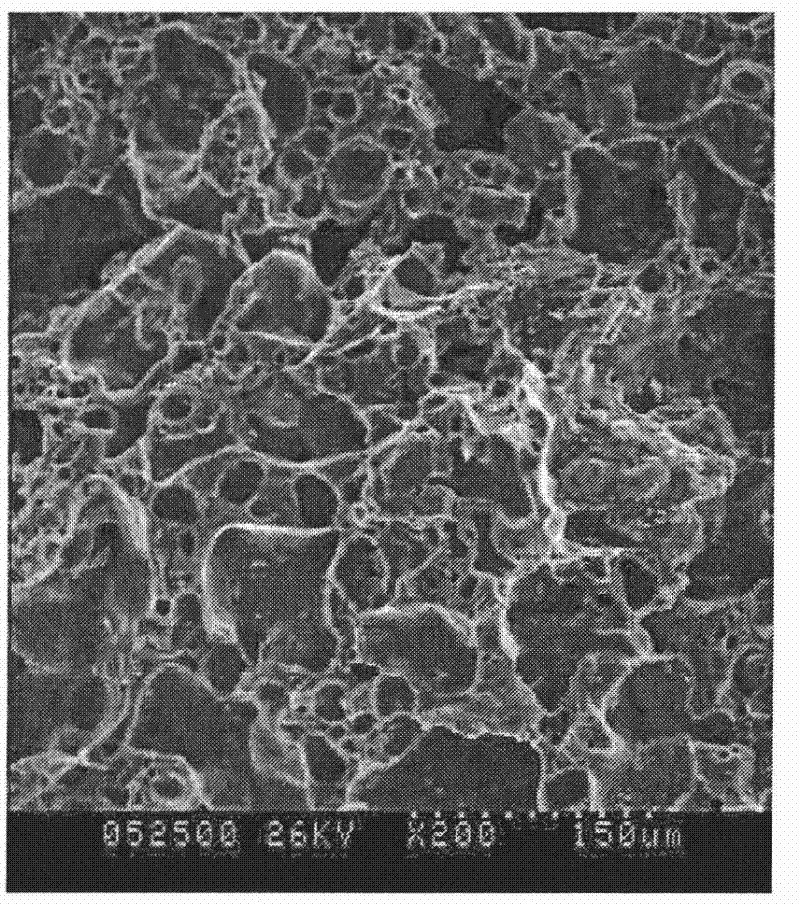

[0044] The appearance of the prepared ultra-light ceramsite is dark brown or dark brown spherical solid with rough surface. The bulk density is 454kg / m 3 , the particle density is 886kg / m 3 , can float in water, the water absorption rate is 5.5wt%, and the expansion rate is 27%.

Embodiment 3

[0048] (1) After the dewatered sludge is dried, the steel slag and clay are dried, the three raw materials are crushed, and sieved with a 100-mesh sieve, the particle diameter is ≤0.15mm;

[0049] (2) Weigh and mix 30wt% of dried and pulverized sludge, 45wt% of clay and 25wt% of converter steel slag, mix well, then add water and stir until viscous, and then make raw meal balls by conventional methods;

[0050] (3) Dry the raw meal balls at room temperature for 20 hours;

[0051] (4) Put the raw material balls into a 380°C box-type resistance furnace, preheat for 20 minutes; transfer to a 1050°C tube-type resistance furnace and bake for 15 minutes; naturally cool to room temperature to obtain ultra-light ceramsite.

[0052] The appearance of the prepared ultra-light ceramsite is dark brown or bright black spherical solid with rough surface, and the bulk density is 487kg / m 3 , the particle density is 925kg / m 3 , can float in water, the water absorption rate is 6.0wt%, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Sintering temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com