Method for preparing processable BN complex phase ceramic capable of improving later-stage hardness

A composite ceramics, hardness technology, applied in the field of machinable BN composite ceramics preparation, to achieve the effect of simple and easy process, small particle size and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

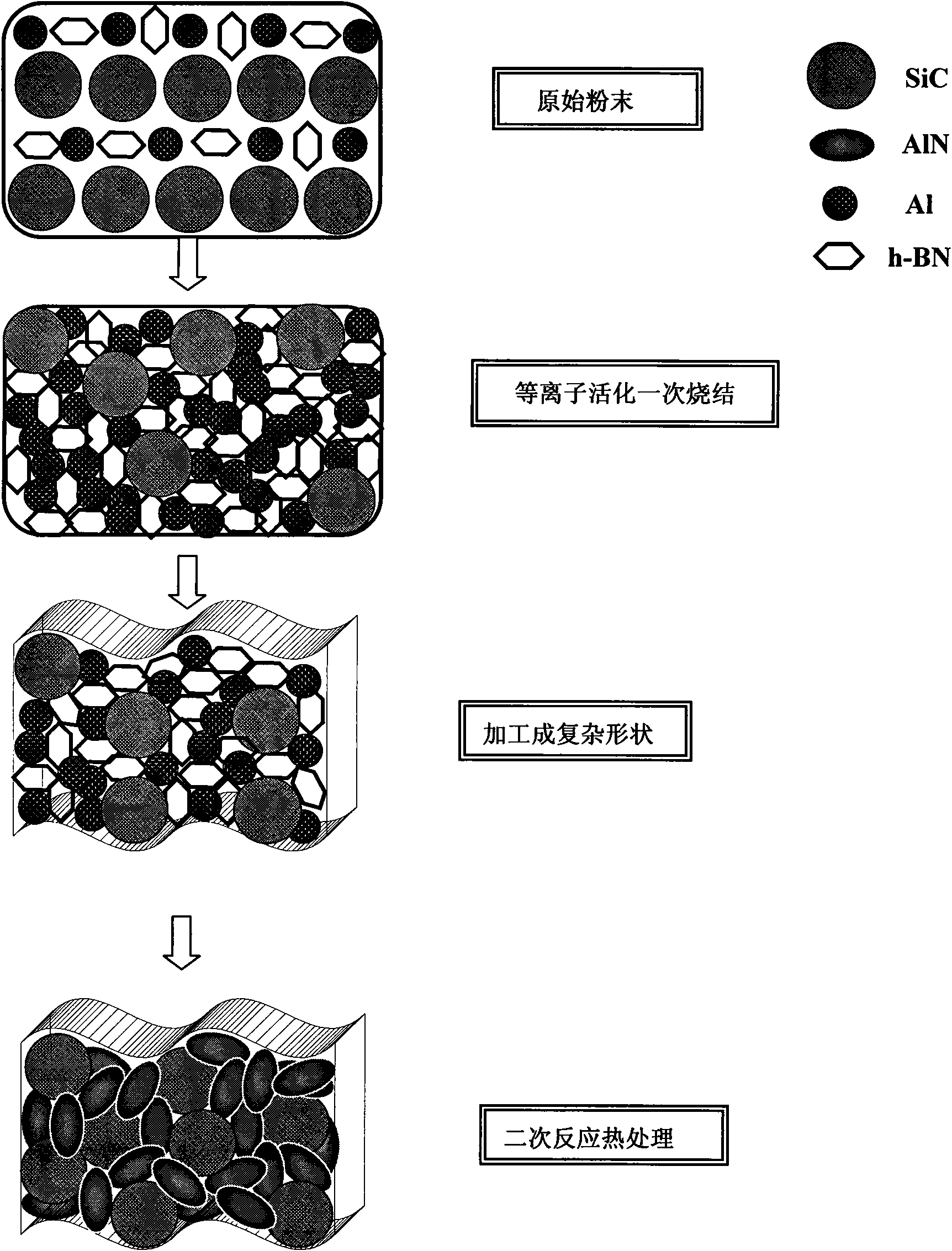

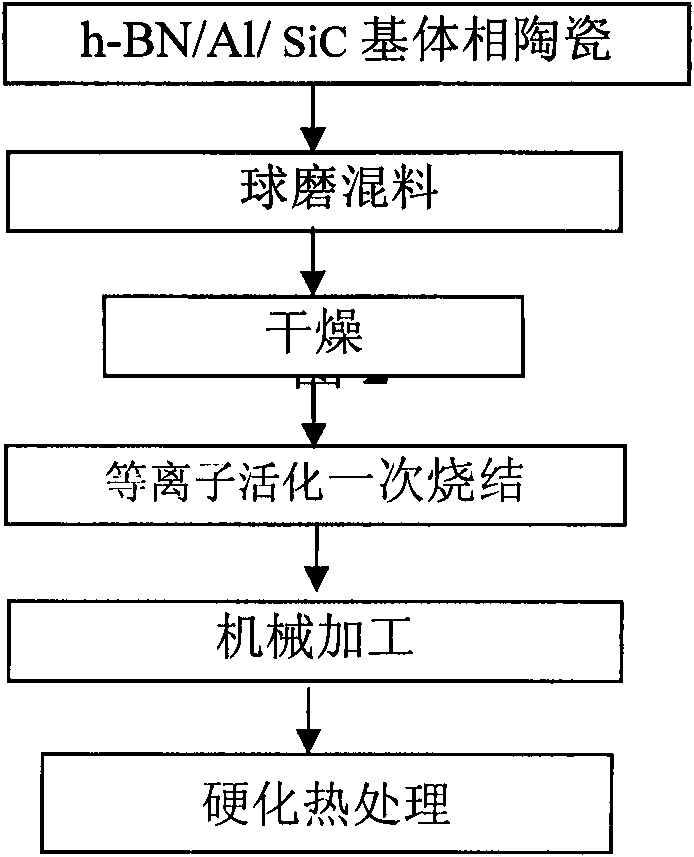

[0025] a. Primary sintering: SiC is used as the ceramic matrix phase, and Al and h-BN are used as toughening and reactive phases. The mass ratio of each component is: SiC: 40%, h-BN: 20%, Al: 40%. The mixed powder was wet milled in a ball mill jar for 24 hours, the medium was absolute ethanol (concentration 99.7%), the balls were agate balls, dried at 70° C., and passed through a 200-mesh sieve. Put the h-BN / Al / SiC mixed powder into a Φ30mm graphite mold, plasma activation and rapid sintering, the first sintering temperature is 1000°C, the heating rate is 300°C / min, the pressure is 30MPa, the vacuum degree is 10Pa, and the heat preservation is 2min. The sintering process adopts Infrared temperature measurement, the sample is cooled with the furnace.

[0026] b. Secondary reaction heat treatment: The h-BN / Al / SiC multiphase ceramics after the primary sintering are processed into the required shape by conventional metal processing, and put into a vacuum furnace. 2 Under gas pro...

Embodiment 2

[0028] SiC is used as the ceramic matrix phase, and Ti and h-BN are used as toughening and reactive phases. The mass ratio of the components is: SiC: 60%, h-BN: 20%, Ti: 20%. Plasma activation fast primary sintering temperature is 900°C, heat preservation 3min; secondary reaction heat treatment temperature 1550°C: heat preservation 1.5h. All the other are with embodiment 1.

Embodiment 3

[0030] to Si 3 N 4 It is the ceramic matrix phase, and Al and h-BN are the toughening and reaction phases. The mass ratio of the components is: Si 3 N 4 : 80%, h-BN: 10%, Al: 10%. Plasma activation fast primary sintering temperature is 800°C, heat preservation 1min; secondary reaction heat treatment temperature 1500°C: heat preservation 1h. All the other are with embodiment 1.

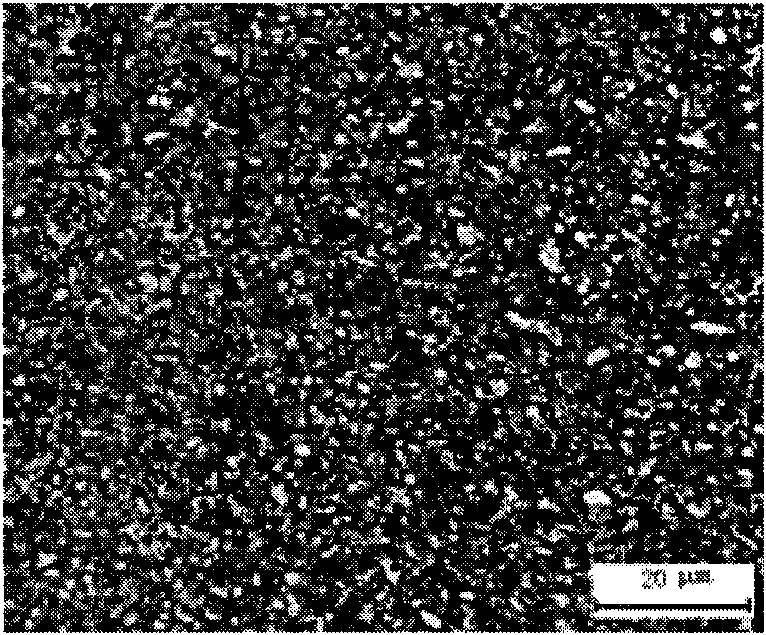

[0031] The surfaces of the samples prepared in the above examples 1 and 2 were polished and subjected to Vickers hardness testing and microstructure research. Table 1 lists the Vickers hardness before and after heat treatment of Example 1: h-BN / Al / SiC Example 2: h-BN / Ti / SiC composite ceramics. It can be seen from Table 1 that after post-reaction heat treatment, the hardness of the machinable ceramics after sintering is greatly improved.

[0032] Table 1 Hardness changes of composite ceramics after primary sintering and secondary hardening treatment by plasma activation

[0033]

[0034] Comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com