Method for producing xylo-oligosaccharide by utilizing cotton seed hulls

A technology of xylooligosaccharides and cottonseed hulls, which is applied in the field of xylooligosaccharides production, can solve the problems of no bifidobacteria value-added factor functionality, complex composition, and weak functionality, etc., to shorten the processing time and shorten the processing time , the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

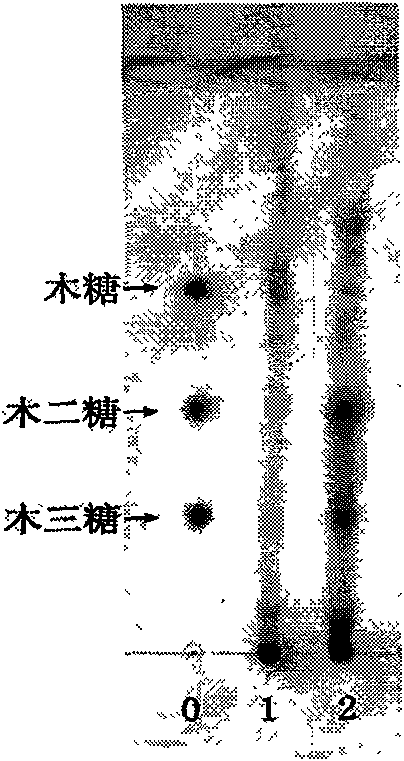

Embodiment 1

[0028] Step 1: Weigh a certain amount of cottonseed hulls, soak in 0.2% (m / v) sulfuric acid solution with a solid-to-liquid ratio of 1:10, pretreat at room temperature for 24 hours, and rinse with water for 3 times, which can effectively remove the pigment substances in the raw materials .

[0029] Step 2: The wet cottonseed hulls are then treated with high-pressure steam at 180°C for 15 minutes.

[0030] Step 3: Add 1.0% (m / m) xylanase after cooling to 50°C with water (based on the dry weight of cottonseed hulls, xylanase is the commercial enzyme Novozymes Pentopan Mono BG), at a temperature of 45-50°C Under the condition of pH 4.0-pH 5.5, the enzyme was hydrolyzed for 36 hours under the condition of slow stirring or shaking.

[0031] Step 4: After the enzymolysis solution is boiled for 10 minutes to kill the enzyme, it is then filtered (filtered by a plate and frame filter) and vacuum concentrated (three-effect or four-effect vacuum concentration) to a sugar concentration o...

Embodiment 2

[0033] Step 1: Weigh a certain amount of cottonseed hulls, soak in 0.5% (m / v) sulfuric acid solution with a solid-to-liquid ratio of 1:10, pretreat at room temperature for 20 hours, and rinse with water for 5 times, which can effectively remove the pigment substances in the raw materials .

[0034] Step 2: The wet cottonseed hulls are then treated with high-pressure steam at 190°C for 7 minutes.

[0035] Step 3: Add 2.5% (m / m) xylanase after cooling to 50°C with water (based on the dry weight of cottonseed hulls, xylanase is the commercial enzyme Novozymes Pentopan Mono BG), at a temperature of 45-50°C And under the condition of pH4.0-pH5.5, after 24 hours of enzymatic hydrolysis under the condition of slow stirring or shaking.

[0036] Step 4: Boil the enzymatic solution for 10 minutes to kill enzymes, then filter and vacuum concentrate to a sugar concentration above 75% (m / m) to obtain xylooligosaccharide syrup.

Embodiment 3

[0038] Step 1: Weigh a certain amount of cottonseed hulls, soak in 0.3% (m / v) sulfuric acid solution with a solid-to-liquid ratio of 1:10, pretreat at room temperature for 24 hours, and rinse with water for 3 times, which can effectively remove the pigment substances in the raw materials .

[0039] Step 2: The wet cottonseed hulls are then treated with high-pressure steam at 185°C for 10 minutes.

[0040] Step 3: Add 1.0% (m / m) xylanase after cooling to 50°C with water (based on the dry weight of cottonseed hulls, xylanase is the commercial enzyme Novozymes Pentopan Mono BG), at a temperature of 45-50°C And under the condition of pH4.0-pH5.5, after 36 hours of enzymatic hydrolysis under the condition of slow stirring or shaking.

[0041] Step 4: Boil the enzymatic solution for 10 minutes to kill enzymes, then filter and vacuum concentrate to a sugar concentration above 75% (m / m) to obtain xylooligosaccharide syrup.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com